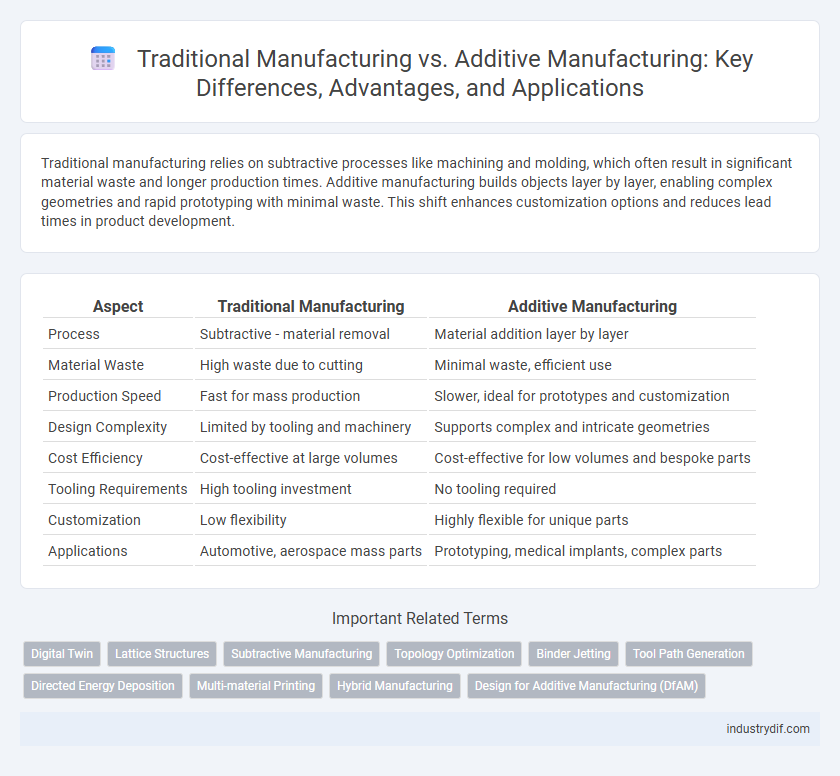

Traditional manufacturing relies on subtractive processes like machining and molding, which often result in significant material waste and longer production times. Additive manufacturing builds objects layer by layer, enabling complex geometries and rapid prototyping with minimal waste. This shift enhances customization options and reduces lead times in product development.

Table of Comparison

| Aspect | Traditional Manufacturing | Additive Manufacturing |

|---|---|---|

| Process | Subtractive - material removal | Material addition layer by layer |

| Material Waste | High waste due to cutting | Minimal waste, efficient use |

| Production Speed | Fast for mass production | Slower, ideal for prototypes and customization |

| Design Complexity | Limited by tooling and machinery | Supports complex and intricate geometries |

| Cost Efficiency | Cost-effective at large volumes | Cost-effective for low volumes and bespoke parts |

| Tooling Requirements | High tooling investment | No tooling required |

| Customization | Low flexibility | Highly flexible for unique parts |

| Applications | Automotive, aerospace mass parts | Prototyping, medical implants, complex parts |

Definition of Traditional Manufacturing

Traditional manufacturing refers to subtractive processes such as machining, casting, and molding, where raw materials are shaped by removing excess material or forming through molds. It typically involves mass production with established tooling and equipment optimized for high-volume output. This method excels in producing parts with consistent mechanical properties but often results in material waste and longer lead times compared to additive manufacturing.

Overview of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, builds components layer by layer directly from digital models, enabling complex geometries unachievable with traditional subtractive methods. This process reduces material waste and shortens production lead times, making it ideal for rapid prototyping and low-volume production runs. Industries such as aerospace, automotive, and healthcare increasingly adopt additive manufacturing to enhance customization, lightweight design, and supply chain flexibility.

Key Processes in Traditional Manufacturing

Traditional manufacturing primarily involves subtractive processes such as machining, casting, and forging, where raw materials are cut, shaped, or molded into final products. These methods rely heavily on tooling, molds, and dies to produce consistent and high-volume outputs with established material properties. The key processes emphasize precision, repeatability, and efficiency in mass production while often requiring longer lead times and higher waste compared to additive manufacturing.

Core Technologies of Additive Manufacturing

Additive Manufacturing relies on core technologies such as Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA), enabling layer-by-layer construction of parts directly from 3D CAD models. These technologies offer enhanced design flexibility, complex geometries, and material efficiency that traditional subtractive manufacturing methods cannot achieve. Rapid prototyping, customization, and reduced material waste are key advantages driven by the fundamental processes of additive manufacturing technologies.

Material Usage and Waste Comparison

Traditional manufacturing typically relies on subtractive processes that remove material from a solid block, resulting in significant waste and higher raw material consumption. Additive manufacturing builds components layer-by-layer, optimizing material usage by depositing only the necessary amount, thereby minimizing waste. This efficiency in material utilization translates into cost savings and sustainability benefits, especially in industries utilizing expensive or scarce materials.

Production Speed and Flexibility

Traditional manufacturing typically involves slower production speeds due to tooling setup and longer lead times, whereas additive manufacturing accelerates the process by enabling direct, layer-by-layer fabrication from digital files. Additive manufacturing offers superior flexibility by allowing rapid design modifications without the need for retooling, facilitating customization and small batch production. Production speed in additive manufacturing is especially advantageous for complex geometries and prototyping, while traditional methods excel in high-volume, standardized manufacturing.

Cost Efficiency and Scalability

Traditional manufacturing typically incurs higher upfront costs due to expensive tooling and longer setup times, making it less cost-efficient for small production runs but scalable for mass production. Additive manufacturing reduces material waste and tooling expenses, offering greater cost efficiency for custom or low-volume parts while enabling rapid scalability through digital workflows. Both methods present distinct economic advantages depending on production volume and complexity requirements in the manufacturing industry.

Applications in Modern Industries

Traditional manufacturing techniques such as casting, forging, and machining dominate mass production in automotive and aerospace industries due to their reliability in high-volume output and material strength. Additive manufacturing excels in producing complex, customized parts with reduced waste, making it ideal for prototyping, medical implants, and aerospace components requiring intricate geometries. Modern industries leverage these methods strategically, combining traditional manufacturing for large-scale production and additive manufacturing for rapid innovation and lightweight, bespoke solutions.

Environmental Impact and Sustainability

Traditional manufacturing often generates significant waste material and consumes large amounts of energy, contributing to higher carbon emissions and resource depletion. Additive manufacturing, also known as 3D printing, reduces material waste by building products layer by layer and can use sustainable or recycled materials, enhancing resource efficiency. The shift to additive manufacturing supports lower greenhouse gas emissions and promotes circular economy principles, making it a more sustainable choice in modern production processes.

Future Trends in Manufacturing Technologies

Future trends in manufacturing technologies emphasize the integration of additive manufacturing with traditional methods to enhance customization and reduce production cycles. Advanced materials and real-time data analytics drive innovation in hybrid manufacturing systems, enabling greater efficiency and precision. The convergence of IoT and AI in smart factories paves the way for predictive maintenance and adaptive manufacturing processes.

Related Important Terms

Digital Twin

Traditional manufacturing relies on physical prototypes and linear processes, limiting real-time monitoring and iterative improvements. Additive manufacturing integrated with digital twin technology enables continuous simulation, predictive maintenance, and rapid design optimization, significantly enhancing production efficiency and reducing time-to-market.

Lattice Structures

Lattice structures in additive manufacturing offer superior weight reduction and material efficiency compared to traditional manufacturing methods, enabling complex geometries that are otherwise impossible to produce. These optimized lattice designs enhance strength-to-weight ratios and thermal management, making them ideal for aerospace, automotive, and medical device applications.

Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block through machining processes like milling, turning, and drilling to create precise components. This method excels in producing high-strength parts with tight tolerances but often results in significant material waste compared to additive manufacturing techniques.

Topology Optimization

Topology optimization in additive manufacturing enables the production of complex, lightweight structures that traditional manufacturing cannot achieve due to tooling and material constraints. This technique reduces material waste and enhances performance by strategically distributing material based on stress analysis, offering a significant advantage over conventional subtractive methods.

Binder Jetting

Binder Jetting in additive manufacturing enables complex geometries and rapid prototyping with reduced material waste compared to traditional subtractive methods. This layer-by-layer deposition process uses a liquid binding agent to fuse powder particles, offering cost-effective production for metal and ceramic parts with minimal thermal distortion.

Tool Path Generation

Traditional manufacturing relies on predetermined tool path generation using CNC machining with fixed tool movements based on subtractive processes, while additive manufacturing utilizes dynamic tool path generation that adapts to layer-by-layer material deposition. Optimized tool path algorithms in additive manufacturing enhance precision, reduce material waste, and allow complex geometries unattainable by conventional methods.

Directed Energy Deposition

Directed Energy Deposition (DED) in additive manufacturing enables precise metal part fabrication by using focused thermal energy to melt materials as they are deposited, offering superior control and material efficiency compared to traditional subtractive manufacturing methods. This technology allows complex geometries and repairs of high-value components that are challenging or impossible to achieve through conventional machining or casting.

Multi-material Printing

Traditional manufacturing relies on subtractive techniques that often limit the integration of multiple materials in a single component, resulting in higher assembly costs and reduced design flexibility. Additive manufacturing, particularly multi-material printing, enables the precise deposition of diverse materials within one build process, enhancing product customization, reducing material waste, and enabling complex functional gradients.

Hybrid Manufacturing

Hybrid manufacturing integrates traditional subtractive processes like CNC machining with additive manufacturing techniques such as 3D printing, enabling complex geometries and enhanced material properties in a single workflow. This approach reduces production time, lowers material waste, and improves overall manufacturing precision compared to using either method independently.

Design for Additive Manufacturing (DfAM)

Design for Additive Manufacturing (DfAM) leverages the layer-by-layer building process to create complex geometries and lightweight structures that traditional manufacturing cannot achieve due to material removal constraints and tooling limitations. Optimizing part orientation, support structures, and material usage in DfAM enhances performance, reduces waste, and enables rapid prototyping and customization unmatched by subtractive or formative manufacturing methods.

Traditional Manufacturing vs Additive Manufacturing Infographic

industrydif.com

industrydif.com