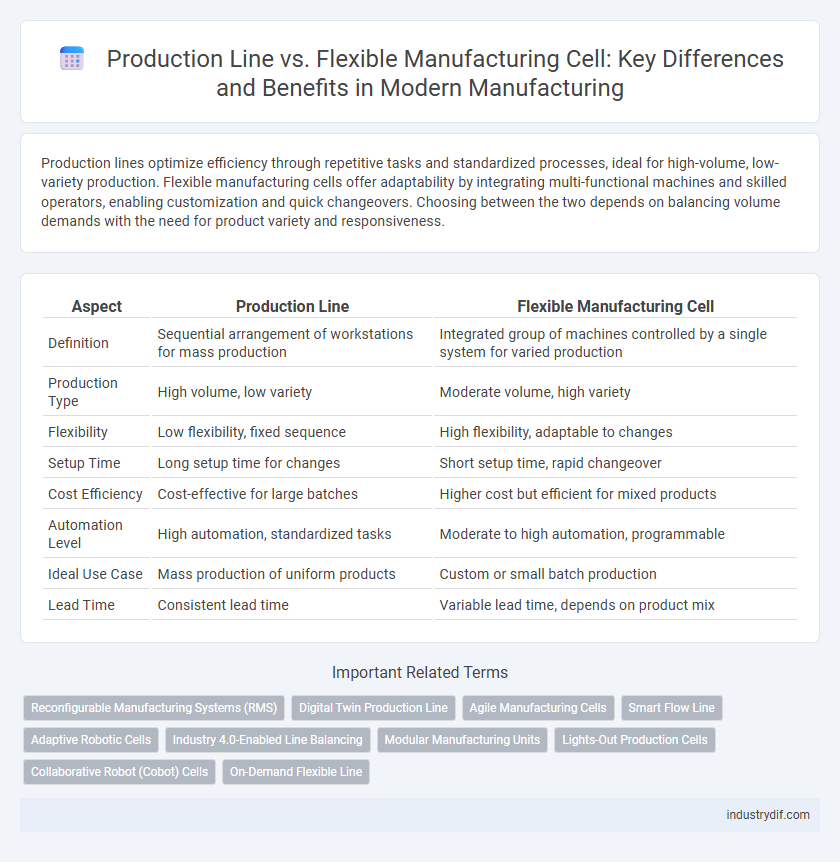

Production lines optimize efficiency through repetitive tasks and standardized processes, ideal for high-volume, low-variety production. Flexible manufacturing cells offer adaptability by integrating multi-functional machines and skilled operators, enabling customization and quick changeovers. Choosing between the two depends on balancing volume demands with the need for product variety and responsiveness.

Table of Comparison

| Aspect | Production Line | Flexible Manufacturing Cell |

|---|---|---|

| Definition | Sequential arrangement of workstations for mass production | Integrated group of machines controlled by a single system for varied production |

| Production Type | High volume, low variety | Moderate volume, high variety |

| Flexibility | Low flexibility, fixed sequence | High flexibility, adaptable to changes |

| Setup Time | Long setup time for changes | Short setup time, rapid changeover |

| Cost Efficiency | Cost-effective for large batches | Higher cost but efficient for mixed products |

| Automation Level | High automation, standardized tasks | Moderate to high automation, programmable |

| Ideal Use Case | Mass production of uniform products | Custom or small batch production |

| Lead Time | Consistent lead time | Variable lead time, depends on product mix |

Introduction to Production Lines and Flexible Manufacturing Cells

Production lines consist of sequential workstations designed for high-volume, repetitive manufacturing processes, optimizing efficiency through standardized tasks. Flexible manufacturing cells are configured with multiple machines and robotic systems allowing for rapid changeovers and customized production runs. Both approaches enhance productivity; production lines favor consistency and scale, while flexible cells prioritize adaptability and product variation.

Key Differences between Production Lines and Flexible Manufacturing Cells

Production lines are designed for high-volume, repetitive manufacturing with fixed sequences and specialized workstations, ensuring consistent output and low unit costs. Flexible manufacturing cells incorporate programmable machines and robotic systems allowing rapid changeovers and customization for varied product types, enhancing adaptability and reducing downtime. The key difference lies in production lines prioritizing efficiency through standardization, while flexible manufacturing cells emphasize versatility for mixed production demands.

Workflow and Layout Comparison

Production lines use a linear workflow designed for high-volume, consistent output, with fixed machines arranged in sequence to optimize efficiency and minimize downtime. Flexible manufacturing cells feature a modular layout with robotic arms and CNC machines configured for quick changeovers, supporting batch production and customization with reduced setup time. Workflow in flexible cells adapts dynamically to product variations, while production lines emphasize standardized processes to maintain steady throughput.

Automation Levels in Production Lines vs Flexible Manufacturing Cells

Production lines typically feature high levels of automation designed for repetitive, high-volume manufacturing tasks, enabling consistent output with minimal human intervention. Flexible manufacturing cells incorporate moderate to advanced automation but emphasize adaptability, allowing quick changeovers and customized production runs with robotic workstations and programmable machinery. Automation in production lines maximizes efficiency for standardized products, whereas flexible manufacturing cells balance automation with versatility to handle varied product types and smaller batch sizes.

Adaptability to Product Variations

Production lines offer high efficiency for mass production but lack adaptability to product variations, making them less suitable for custom or small-batch manufacturing. Flexible manufacturing cells excel in handling diverse product types due to their modular setup and programmable machinery, allowing quick adjustments without major downtime. This adaptability reduces changeover times and supports a wider range of product variants, enhancing responsiveness to market demands.

Cost Implications: Initial Investment and Operational Expenses

Production lines generally require higher initial investment due to extensive dedicated machinery and infrastructure, while flexible manufacturing cells involve lower startup costs driven by versatile equipment and modular setups. Operational expenses in production lines tend to be stable but can escalate with changes in product demand or design, whereas flexible cells offer cost efficiency through adaptability, reducing downtime and tooling changes. Analyzing specific production volumes and product variety is essential to determine long-term cost benefits between these approaches.

Impact on Labor and Workforce Requirements

Production lines require specialized labor with repetitive task skills, leading to a stable but less adaptable workforce profile. Flexible manufacturing cells demand multi-skilled workers capable of operating varied equipment, increasing workforce versatility and reducing downtime. This shift impacts labor costs and training programs, necessitating investment in cross-functional skills development.

Quality Control Approaches in Both Systems

Production lines prioritize standardized quality control through continuous inspection and automated testing, ensuring uniform product consistency across high-volume output. Flexible manufacturing cells employ adaptable quality control methods, leveraging real-time monitoring and adjustable process parameters to maintain quality amidst varied product configurations. Both systems integrate statistical process control (SPC) tools, but flexible cells emphasize rapid response to deviations due to their dynamic production environment.

Industry Applications and Use Cases

Production lines excel in high-volume, standardized manufacturing such as automotive assembly, where consistent output and efficiency are critical. Flexible manufacturing cells suit industries requiring customization and variety, like aerospace or electronics, enabling rapid switching between products with minimal downtime. The choice depends on production scale, product complexity, and demand variability within industry-specific applications.

Choosing the Right System for Your Manufacturing Needs

Evaluating production line systems versus flexible manufacturing cells requires analyzing product volume, variety, and changeover frequency. Production lines excel in high-volume, standardized manufacturing with minimal variation, maximizing efficiency and throughput. Flexible manufacturing cells are ideal for lower-volume, high-mix environments, offering adaptability and rapid reconfiguration to meet evolving production demands.

Related Important Terms

Reconfigurable Manufacturing Systems (RMS)

Reconfigurable Manufacturing Systems (RMS) integrate the efficiency of traditional production lines with the adaptability of flexible manufacturing cells, enabling rapid reconfiguration to meet changing production demands. RMS optimize resource utilization, reduce downtime, and enhance scalability by allowing modular equipment and programmable control systems tailored for dynamic product customization and volume variations.

Digital Twin Production Line

Digital Twin Production Line integrates real-time data and virtual simulations to optimize manufacturing efficiency, enabling precise monitoring and predictive maintenance in contrast to traditional Flexible Manufacturing Cells that prioritize adaptability over digital feedback. This technology enhances decision-making by creating a dynamic virtual replica of the production process, reducing downtime and improving product quality through continuous digital optimization.

Agile Manufacturing Cells

Agile manufacturing cells enhance production efficiency by enabling quick reconfiguration of machinery and workflows to accommodate varying product designs and volumes, contrasting with traditional production lines that are often rigid and optimized for mass production. These flexible cells reduce downtime and increase responsiveness to market demand, supporting just-in-time manufacturing and minimizing inventory costs.

Smart Flow Line

Smart Flow Line enhances traditional production lines by integrating automated systems and real-time data analytics, boosting efficiency and reducing downtime. Unlike flexible manufacturing cells, it maintains high-volume output while allowing quick adjustments to product variations through intelligent workflow management.

Adaptive Robotic Cells

Adaptive robotic cells in flexible manufacturing systems enhance production efficiency by enabling rapid reconfiguration for diverse product types, unlike traditional production lines designed for repetitive tasks. These robotic cells integrate advanced sensors and AI to optimize workflows, reduce downtime, and improve customization in high-mix, low-volume manufacturing environments.

Industry 4.0-Enabled Line Balancing

Industry 4.0-enabled line balancing in production lines leverages real-time data analytics, IoT sensors, and AI-driven automation to optimize workflow efficiency and minimize downtime. Flexible manufacturing cells enhance adaptability by integrating smart robotics and modular systems, allowing rapid reconfiguration to meet changing production demands while maintaining balanced workloads.

Modular Manufacturing Units

Modular manufacturing units enhance production line efficiency by enabling reconfigurable setups that adapt quickly to changing product designs and volumes. Flexible manufacturing cells improve responsiveness and reduce downtime by integrating automated machinery and robotics within modular units, optimizing workflow and resource utilization.

Lights-Out Production Cells

Lights-out production cells in manufacturing leverage automated, unattended operation to maximize efficiency and reduce labor costs, outperforming traditional production lines with fixed workflows. Flexible manufacturing cells adapt quickly to product variations, but lights-out cells specifically enable 24/7 operation with minimal human intervention, boosting throughput and precision in high-volume environments.

Collaborative Robot (Cobot) Cells

Collaborative robot (cobot) cells in flexible manufacturing environments enhance adaptability by seamlessly integrating with human operators for customized production, contrasting traditional production lines that prioritize high-volume, repetitive tasks with limited flexibility. Cobot cells optimize space and workflow efficiency, enabling rapid reconfiguration to accommodate varying product models and reduce downtime, driving agility in modern manufacturing processes.

On-Demand Flexible Line

An On-Demand Flexible Line integrates adaptable machinery and modular setups to efficiently switch between diverse product types, minimizing downtime compared to traditional production lines. This approach enhances responsiveness to market fluctuations while maintaining high throughput and consistent quality control in manufacturing environments.

Production Line vs Flexible Manufacturing Cell Infographic

industrydif.com

industrydif.com