CNC machining offers precise, high-quality cuts using subtractive processes ideal for complex geometries and tight tolerances. Hybrid manufacturing combines additive and subtractive techniques, enhancing flexibility by building parts layer-by-layer before machining critical features. This integration reduces material waste and production time while enabling the creation of intricate designs that traditional CNC alone cannot achieve.

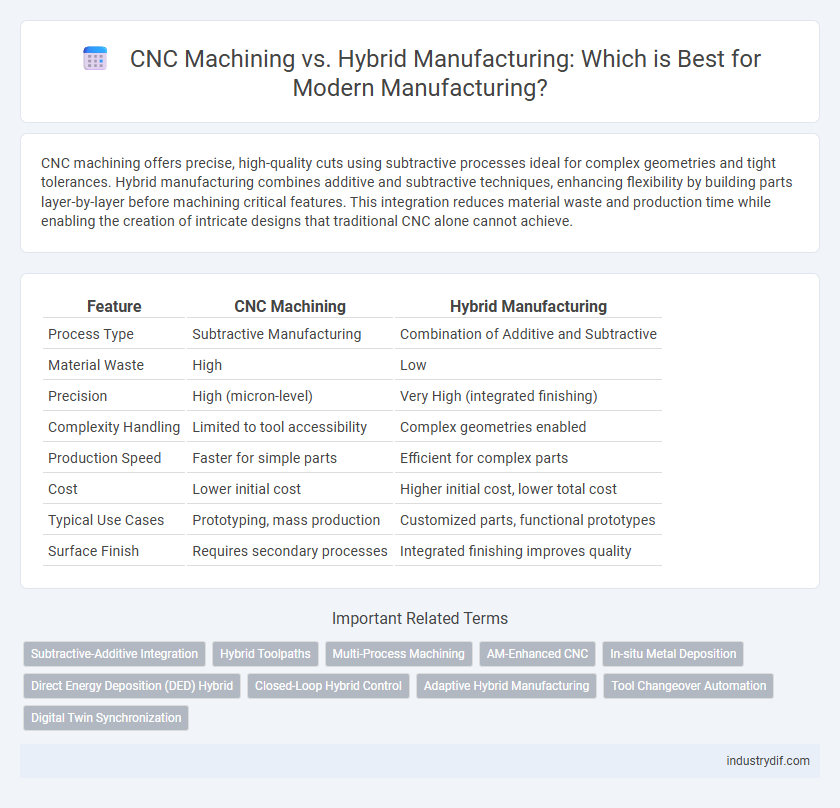

Table of Comparison

| Feature | CNC Machining | Hybrid Manufacturing |

|---|---|---|

| Process Type | Subtractive Manufacturing | Combination of Additive and Subtractive |

| Material Waste | High | Low |

| Precision | High (micron-level) | Very High (integrated finishing) |

| Complexity Handling | Limited to tool accessibility | Complex geometries enabled |

| Production Speed | Faster for simple parts | Efficient for complex parts |

| Cost | Lower initial cost | Higher initial cost, lower total cost |

| Typical Use Cases | Prototyping, mass production | Customized parts, functional prototypes |

| Surface Finish | Requires secondary processes | Integrated finishing improves quality |

Introduction to CNC Machining and Hybrid Manufacturing

CNC machining uses computer-controlled tools to precisely cut and shape metal or plastic parts, offering high accuracy and repeatability in manufacturing processes. Hybrid manufacturing combines additive manufacturing (3D printing) with subtractive methods like CNC machining, enabling complex geometries and enhanced material properties in a single workflow. This integration improves production efficiency, reduces lead times, and expands design possibilities across aerospace, automotive, and medical industries.

Core Principles of CNC Machining

CNC machining operates on the core principle of subtractive manufacturing, where precise computer-controlled cutting tools remove material from a solid block to create complex parts. It relies on high-precision machine programming and rigid tool paths to achieve dimensional accuracy and surface finish critical for aerospace, automotive, and medical applications. Unlike hybrid manufacturing, which combines additive and subtractive processes, CNC machining focuses exclusively on material removal for repeatable, high-tolerance production runs.

Fundamental Concepts of Hybrid Manufacturing

Hybrid manufacturing integrates CNC machining with additive manufacturing processes to combine precise subtractive techniques and complex geometric building in a single workflow. This approach optimizes production efficiency by enabling layer-by-layer material addition followed by CNC-based finishing, enhancing dimensional accuracy and surface quality. The fundamental concept revolves around leveraging the strengths of both methods to fabricate components with complex shapes and fine tolerances that are challenging for conventional machining alone.

Key Differences Between CNC and Hybrid Manufacturing

CNC machining relies exclusively on subtractive processes to shape materials with high precision, while hybrid manufacturing combines additive and subtractive techniques to enhance versatility and reduce production time. Hybrid systems enable complex geometries and internal features that are difficult to achieve with CNC machining alone, improving design flexibility and material efficiency. Key differences also include CNC's emphasis on repeatability and surface finish, whereas hybrid manufacturing offers improved customization and reduced waste through integrated processes.

Advantages of CNC Machining in Modern Manufacturing

CNC machining offers unparalleled precision and repeatability, making it essential for producing high-quality components with tight tolerances in modern manufacturing. Its automation capabilities reduce labor costs and increase production speed, enhancing overall efficiency in industries like aerospace, automotive, and electronics. CNC machines also support a wide range of materials, enabling versatility and scalability in manufacturing complex parts.

Benefits of Hybrid Manufacturing Technologies

Hybrid manufacturing technologies combine additive and subtractive processes in a single machine, enhancing precision and reducing production time. These systems enable complex geometries with improved surface finishes and tighter tolerances compared to traditional CNC machining alone. The integration of both methods minimizes material waste and increases flexibility, supporting rapid prototyping and low-volume production efficiently.

Comparative Analysis: Cost, Speed, and Precision

CNC machining offers high precision and consistent quality with moderate operational costs, making it ideal for small to medium batch productions. Hybrid manufacturing combines additive and subtractive processes, reducing lead times and material waste while enhancing complex geometries, but typically involves higher initial investment. Cost-efficiency varies depending on production volume and complexity, with hybrid manufacturing excelling in speed and versatility for advanced, custom components.

Application Areas for CNC and Hybrid Manufacturing

CNC machining is extensively utilized in aerospace, automotive, and medical device manufacturing for producing high-precision components with complex geometries from metals and plastics. Hybrid manufacturing combines additive and subtractive processes, enabling the production of intricate parts with enhanced mechanical properties, ideal for aerospace, tooling, and customized medical implants. Both methods serve high-precision industries, but hybrid manufacturing excels in applications requiring complex internal structures and material efficiency.

Challenges and Limitations of Each Approach

CNC machining faces challenges including high tooling costs, limited complexity for internal features, and material waste from subtractive processes. Hybrid manufacturing struggles with integrating additive and subtractive steps, leading to increased setup times and equipment costs. Both approaches require skilled operators, but hybrid systems often demand advanced expertise due to process complexity.

Future Trends in CNC and Hybrid Manufacturing

Future trends in CNC machining emphasize increased automation, integration with AI-driven predictive maintenance, and the adoption of advanced materials to enhance precision and efficiency. Hybrid manufacturing combines additive and subtractive processes, enabling more complex geometries and reduced production times, which is becoming critical for aerospace and medical industries. The convergence of digital twins, real-time monitoring, and adaptive control systems will drive the evolution of both CNC and hybrid manufacturing processes toward smarter, more flexible production environments.

Related Important Terms

Subtractive-Additive Integration

CNC machining excels in precision subtractive processes by removing material from a solid block, delivering high-quality surface finishes and tight tolerances. Hybrid manufacturing integrates additive manufacturing techniques with CNC machining, enabling complex part creation by depositing material and then precisely machining it, which reduces waste and shortens production cycles.

Hybrid Toolpaths

Hybrid toolpaths in CNC machining combine additive and subtractive processes within a single setup, enhancing manufacturing flexibility and precision. This integration reduces cycle times and material waste, making hybrid manufacturing ideal for complex geometries and customized production runs.

Multi-Process Machining

Multi-process machining integrates CNC machining with additive and subtractive methods, enhancing manufacturing precision and efficiency by consolidating multiple operations into a single setup. Hybrid manufacturing combines these technologies to reduce production time, improve surface finish, and enable complex geometries unattainable through traditional CNC machining alone.

AM-Enhanced CNC

AM-enhanced CNC combines additive manufacturing with traditional subtractive CNC machining, enabling complex geometries, reduced material waste, and shorter production cycles in manufacturing. This hybrid approach optimizes precision and flexibility, enhancing surface finish quality and allowing rapid prototyping alongside mass production scalability.

In-situ Metal Deposition

In-situ metal deposition in hybrid manufacturing combines additive and subtractive processes directly on the CNC machine, enhancing precision and reducing production time compared to traditional CNC machining alone. This integration allows for complex geometries and repair applications by enabling layer-by-layer metal build-up followed by high-accuracy machining in a single setup.

Direct Energy Deposition (DED) Hybrid

Direct Energy Deposition (DED) hybrid manufacturing integrates CNC machining with additive processes to enhance precision and reduce material waste by building complex geometries layer-by-layer before finishing with subtractive methods. This combination improves production efficiency and enables the creation of parts with superior mechanical properties and intricate internal features unattainable through traditional CNC machining alone.

Closed-Loop Hybrid Control

Closed-loop hybrid control in CNC machining integrates real-time feedback from sensors to dynamically adjust machining parameters, enhancing precision and reducing defects. This approach contrasts with traditional CNC processes by combining additive and subtractive methods within a single system, improving efficiency and enabling the manufacture of complex geometries with tighter tolerances.

Adaptive Hybrid Manufacturing

Adaptive Hybrid Manufacturing integrates CNC machining with additive processes, optimizing precision and flexibility by dynamically adjusting toolpaths and deposition based on real-time feedback. This approach enhances material utilization and reduces production time, surpassing traditional CNC machining by enabling complex geometries and on-demand customization.

Tool Changeover Automation

CNC machining offers precise tool changeover automation through pre-programmed sequences, minimizing downtime and ensuring consistent production quality. Hybrid manufacturing integrates additive and subtractive processes with automated tool change systems, enabling seamless transitions that enhance efficiency and reduce manual intervention.

Digital Twin Synchronization

CNC machining relies on precise programming and tool paths to shape materials, while hybrid manufacturing integrates additive and subtractive processes for complex geometries. Digital twin synchronization ensures real-time data exchange and process monitoring, optimizing both CNC machining accuracy and hybrid manufacturing flexibility for enhanced production efficiency.

CNC Machining vs Hybrid Manufacturing Infographic

industrydif.com

industrydif.com