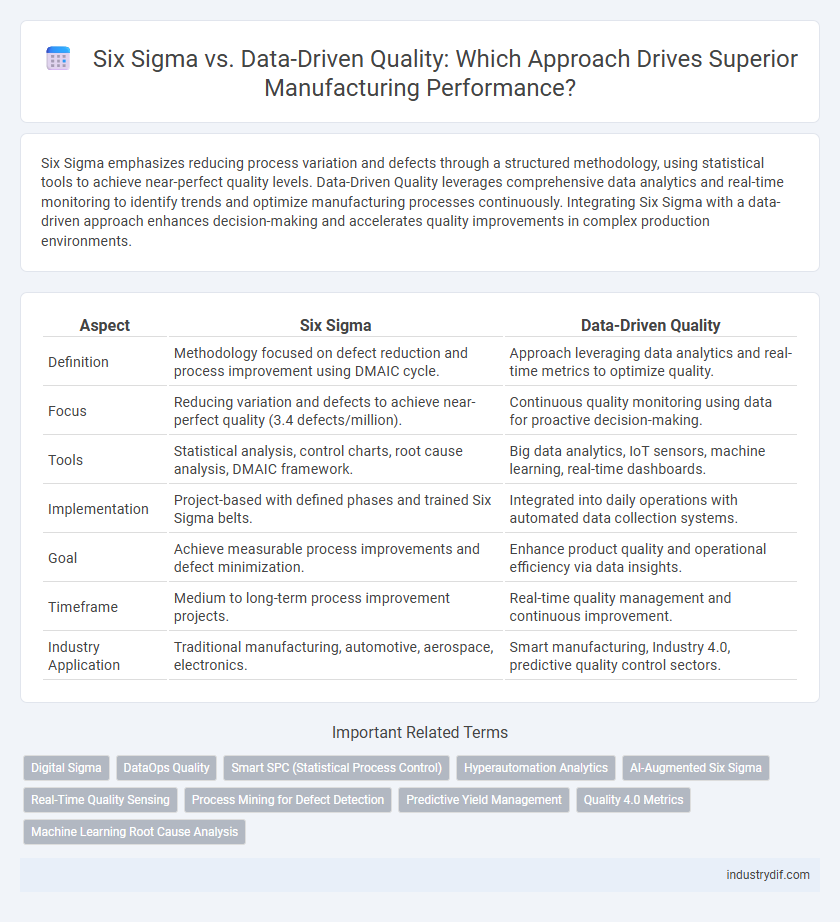

Six Sigma emphasizes reducing process variation and defects through a structured methodology, using statistical tools to achieve near-perfect quality levels. Data-Driven Quality leverages comprehensive data analytics and real-time monitoring to identify trends and optimize manufacturing processes continuously. Integrating Six Sigma with a data-driven approach enhances decision-making and accelerates quality improvements in complex production environments.

Table of Comparison

| Aspect | Six Sigma | Data-Driven Quality |

|---|---|---|

| Definition | Methodology focused on defect reduction and process improvement using DMAIC cycle. | Approach leveraging data analytics and real-time metrics to optimize quality. |

| Focus | Reducing variation and defects to achieve near-perfect quality (3.4 defects/million). | Continuous quality monitoring using data for proactive decision-making. |

| Tools | Statistical analysis, control charts, root cause analysis, DMAIC framework. | Big data analytics, IoT sensors, machine learning, real-time dashboards. |

| Implementation | Project-based with defined phases and trained Six Sigma belts. | Integrated into daily operations with automated data collection systems. |

| Goal | Achieve measurable process improvements and defect minimization. | Enhance product quality and operational efficiency via data insights. |

| Timeframe | Medium to long-term process improvement projects. | Real-time quality management and continuous improvement. |

| Industry Application | Traditional manufacturing, automotive, aerospace, electronics. | Smart manufacturing, Industry 4.0, predictive quality control sectors. |

Understanding Six Sigma in Modern Manufacturing

Six Sigma in modern manufacturing focuses on minimizing defects and process variability through data-driven methodologies and statistical analysis. This approach uses DMAIC (Define, Measure, Analyze, Improve, Control) to improve production efficiency and product quality. Integrating Six Sigma with real-time data collection enhances decision-making and drives continuous improvement in manufacturing operations.

Defining Data-Driven Quality Approaches

Data-driven quality approaches leverage real-time analytics and statistical tools to enhance manufacturing processes by identifying root causes of defects and optimizing production parameters. Unlike traditional Six Sigma, which follows a structured DMAIC methodology, data-driven quality emphasizes continuous data collection and machine learning integration for adaptive decision-making. This paradigm shift enables manufacturers to predict quality issues proactively and improve yield with minimal human intervention.

Historical Evolution: Six Sigma and Data-Driven Quality

Six Sigma originated in the 1980s as a data-driven methodology aimed at reducing defects to improve manufacturing quality by utilizing statistical tools and DMAIC processes. Data-Driven Quality has evolved from Six Sigma by integrating real-time data analytics, machine learning, and Industry 4.0 technologies to enhance predictive quality control and decision-making. The historical evolution reflects a shift from traditional statistical approaches to advanced data science techniques that optimize manufacturing efficiency and product quality.

Key Methodologies: DMAIC vs Data Analytics

The DMAIC methodology in Six Sigma emphasizes a structured problem-solving approach through Define, Measure, Analyze, Improve, and Control phases to reduce defects in manufacturing processes. Data-Driven Quality relies extensively on advanced data analytics techniques, including machine learning and predictive modeling, to identify patterns and optimize process parameters in real-time. Integrating DMAIC's systematic framework with robust data analytics enhances precision in quality improvements and operational efficiency.

Metrics and Measurement Tools in Each Approach

Six Sigma employs specific metrics such as Defects Per Million Opportunities (DPMO) and Sigma Levels to quantitatively measure process improvements, utilizing tools like Control Charts and Failure Mode and Effects Analysis (FMEA) for precise defect identification. Data-Driven Quality focuses on real-time data analytics and key performance indicators (KPIs) derived from machine sensors and production databases, leveraging advanced tools such as Statistical Process Control (SPC) software and predictive analytics platforms. Both approaches emphasize accurate measurement but differ in their reliance on predefined statistical methodologies versus adaptive, continuous data monitoring.

Benefits of Six Sigma in Industrial Operations

Six Sigma enhances industrial operations by systematically reducing process variation and defects, leading to improved product quality and higher customer satisfaction. Its data-driven methodology drives cost savings through waste elimination and optimized resource utilization, boosting overall operational efficiency. Implementation of Six Sigma fosters a culture of continuous improvement and robust problem-solving skills among employees, which elevates production consistency and competitiveness in the manufacturing sector.

Advantages of Data-Driven Quality for Manufacturing

Data-driven quality in manufacturing harnesses real-time data analytics and advanced sensor technologies to enhance product consistency and reduce defects more efficiently than traditional Six Sigma methods. It enables proactive decision-making by identifying process variations promptly, leading to improved operational agility and reduced downtime. Leveraging big data and machine learning algorithms optimizes production workflows, driving higher yield rates and cost savings in complex manufacturing environments.

Implementing Six Sigma vs Data-Driven Strategies

Implementing Six Sigma in manufacturing centers on reducing defects through DMAIC (Define, Measure, Analyze, Improve, Control) methodology, relying heavily on statistical tools and process mapping to achieve near-perfect quality levels. Data-driven quality strategies prioritize real-time data analytics, machine learning, and IoT integration to continuously monitor production variables and predict potential failures before they occur. Combining Six Sigma's structured problem-solving with advanced data analytics enhances process improvements, maximizes yield, and reduces operational costs by enabling proactive decision-making.

Integration and Hybrid Models in Quality Management

Integrating Six Sigma methodologies with data-driven quality management enhances manufacturing performance by combining statistical rigor with real-time analytics for proactive defect reduction. Hybrid models leverage Six Sigma's DMAIC framework alongside advanced data visualization and machine learning, facilitating faster identification of variation sources and improving process optimization. This synergy supports continuous improvement by enabling data-backed decision-making and fostering a culture of quality excellence across manufacturing operations.

Future Trends: Six Sigma and Data-Driven Quality

Future trends in manufacturing emphasize integrating Six Sigma with data-driven quality approaches, leveraging advanced analytics and artificial intelligence to enhance process optimization. Predictive maintenance and real-time data monitoring enable proactive defect reduction and continuous improvement, aligning with Industry 4.0 standards. The fusion of Six Sigma methodologies with big data analytics accelerates decision-making and drives higher operational efficiency in smart factories.

Related Important Terms

Digital Sigma

Digital Sigma integrates Six Sigma principles with advanced data analytics to optimize manufacturing processes, reducing defects and enhancing product quality. Emphasizing real-time data-driven decision-making, Digital Sigma leverages IoT sensors and AI algorithms to identify process inefficiencies and enable continuous quality improvements.

DataOps Quality

DataOps Quality integrates Six Sigma's precision by emphasizing real-time data management and continuous improvement in manufacturing processes, enhancing defect detection and root cause analysis with automated data pipelines and analytics. Leveraging DataOps Quality accelerates decision-making and operational agility, outperforming traditional Six Sigma methodologies in handling complex, high-volume manufacturing data environments.

Smart SPC (Statistical Process Control)

Smart SPC integrates Six Sigma methodologies with data-driven quality measures, leveraging real-time analytics and machine learning to detect process variations and reduce defects effectively. This approach enhances decision-making by providing precise statistical insights, optimizing manufacturing processes, and achieving higher operational efficiency.

Hyperautomation Analytics

Six Sigma leverages statistical methods to reduce defects and improve process quality, while data-driven quality in hyperautomation analytics integrates AI and machine learning to analyze massive datasets in real-time for predictive insights. Hyperautomation enhances Six Sigma initiatives by automating data collection, enabling continuous monitoring and faster decision-making to drive operational excellence.

AI-Augmented Six Sigma

AI-augmented Six Sigma enhances traditional Six Sigma methodologies by integrating advanced machine learning algorithms and real-time data analytics, enabling more precise defect detection and process optimization in manufacturing. This fusion accelerates continuous improvement cycles and drives higher yield rates compared to conventional data-driven quality approaches reliant solely on historical data analysis.

Real-Time Quality Sensing

Six Sigma utilizes statistical analysis to reduce defects and improve process control, but Real-Time Quality Sensing leverages continuous data streams and sensor integration for immediate detection and correction of quality issues. This data-driven approach enhances responsiveness and enables proactive decision-making, surpassing traditional batch analysis by providing instant insights during manufacturing operations.

Process Mining for Defect Detection

Six Sigma utilizes statistical analysis to reduce process variation and improve quality, while Data-Driven Quality leverages advanced technologies like Process Mining to identify defects by analyzing real-time event logs and process data. Process Mining enhances defect detection by uncovering bottlenecks, deviations, and inefficiencies in manufacturing workflows, enabling targeted improvements and reducing production errors.

Predictive Yield Management

Six Sigma leverages statistical tools and DMAIC methodology to reduce process variation and defects, enhancing yield consistency in manufacturing. Data-Driven Quality, particularly through Predictive Yield Management, utilizes advanced analytics and machine learning algorithms to forecast yield outcomes, enabling proactive adjustments and optimized production efficiency.

Quality 4.0 Metrics

Six Sigma emphasizes defect reduction through statistical control and process improvement, while Data-Driven Quality leverages real-time Industry 4.0 data streams, IoT sensors, and advanced analytics to optimize manufacturing performance. Quality 4.0 metrics integrate predictive maintenance indicators, machine uptime, and process capability indices to enable proactive quality management and continuous operational excellence.

Machine Learning Root Cause Analysis

Six Sigma emphasizes reducing defects through statistical analysis and process control, while Data-Driven Quality leverages machine learning root cause analysis to uncover complex patterns and predict failures proactively. Integrating machine learning enhances root cause identification by analyzing vast manufacturing data, enabling faster, more accurate decision-making and improving overall process efficiency.

Six Sigma vs Data-Driven Quality Infographic

industrydif.com

industrydif.com