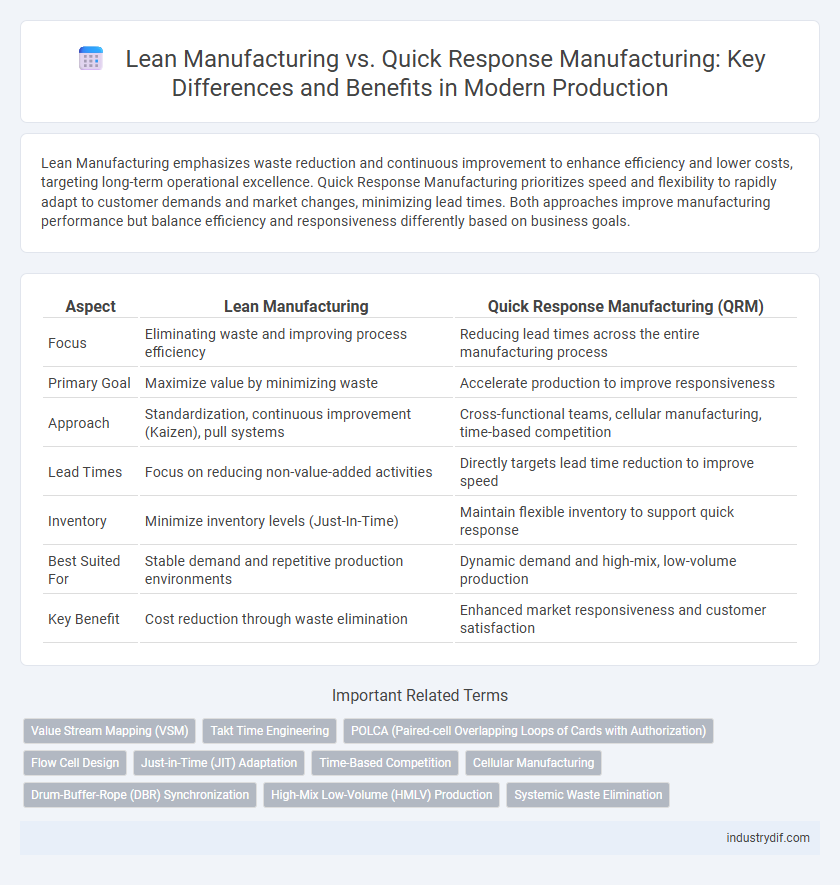

Lean Manufacturing emphasizes waste reduction and continuous improvement to enhance efficiency and lower costs, targeting long-term operational excellence. Quick Response Manufacturing prioritizes speed and flexibility to rapidly adapt to customer demands and market changes, minimizing lead times. Both approaches improve manufacturing performance but balance efficiency and responsiveness differently based on business goals.

Table of Comparison

| Aspect | Lean Manufacturing | Quick Response Manufacturing (QRM) |

|---|---|---|

| Focus | Eliminating waste and improving process efficiency | Reducing lead times across the entire manufacturing process |

| Primary Goal | Maximize value by minimizing waste | Accelerate production to improve responsiveness |

| Approach | Standardization, continuous improvement (Kaizen), pull systems | Cross-functional teams, cellular manufacturing, time-based competition |

| Lead Times | Focus on reducing non-value-added activities | Directly targets lead time reduction to improve speed |

| Inventory | Minimize inventory levels (Just-In-Time) | Maintain flexible inventory to support quick response |

| Best Suited For | Stable demand and repetitive production environments | Dynamic demand and high-mix, low-volume production |

| Key Benefit | Cost reduction through waste elimination | Enhanced market responsiveness and customer satisfaction |

Introduction to Lean Manufacturing and Quick Response Manufacturing

Lean Manufacturing emphasizes waste reduction through continuous improvement, efficient resource utilization, and streamlined production processes to maximize value for customers. Quick Response Manufacturing prioritizes speed and flexibility by rapidly adjusting production schedules and minimizing lead times to meet fluctuating customer demands. Both methodologies aim to enhance manufacturing efficiency but differ in their core focus on waste elimination versus rapid responsiveness.

Core Principles of Lean Manufacturing

Lean Manufacturing centers on minimizing waste by implementing continuous improvement, just-in-time production, and respect for people throughout the value stream. Core principles include identifying value from the customer's perspective, mapping the value stream to eliminate non-value-added activities, establishing flow to reduce delays, creating pull systems to produce only what is needed, and pursuing perfection through ongoing refinement. These principles drive efficiency, reduce inventory, and enhance product quality across manufacturing operations.

Core Principles of Quick Response Manufacturing

Quick Response Manufacturing (QRM) centers on reducing lead times across all manufacturing processes to enhance responsiveness and flexibility, differing from Lean Manufacturing's emphasis on waste elimination. Core principles of QRM include time-based competition, organization into cross-functional cells, and the use of dynamic scheduling to minimize delays and improve flow. This approach prioritizes rapid response to customer demands by integrating product design, manufacturing, and business functions to shorten the entire product realization cycle.

Key Differences Between Lean and QRM

Lean Manufacturing emphasizes waste reduction and process efficiency through standardized workflows and continuous improvement techniques, targeting long production runs with minimal inventory. Quick Response Manufacturing (QRM) prioritizes reducing lead times across all functions, enabling rapid response to customer demand and promoting flexible, small-batch production. While Lean focuses on cost efficiency and eliminating non-value-added activities, QRM centers on agility and speed to enhance overall responsiveness in dynamic market conditions.

Application Areas: Lean vs QRM

Lean Manufacturing is predominantly applied in high-volume, low-mix environments aiming to eliminate waste and optimize standard processes. Quick Response Manufacturing (QRM) targets high-mix, low-volume production settings where reducing lead times and improving responsiveness to customer demand are critical. Lean excels in stable production flows, while QRM is ideal for dynamic markets requiring rapid adaptability and custom orders.

Impact on Lead Time Reduction

Lean Manufacturing minimizes lead time by eliminating waste and enhancing process efficiency through tactics like value stream mapping and continuous flow. Quick Response Manufacturing shortens lead time by emphasizing rapid changeovers, flexible production, and close supplier integration to meet fluctuating customer demands. Both approaches significantly reduce lead time, but Quick Response Manufacturing excels in responsiveness to market variability while Lean focuses on stable, incremental improvements.

Effects on Inventory Management

Lean Manufacturing minimizes inventory by emphasizing waste reduction and just-in-time production, which leads to lower carrying costs and reduced stock obsolescence. Quick Response Manufacturing improves inventory flexibility through rapid adaptation to customer demand, enabling faster turnover and reduced excess inventory. Both methods enhance inventory management, but Lean focuses on efficiency and waste elimination, while Quick Response prioritizes responsiveness and agility.

Suitability for High-Mix, Low-Volume Production

Lean Manufacturing emphasizes waste reduction and efficiency, making it suitable for stable, repetitive production environments but less flexible in high-mix, low-volume scenarios. Quick Response Manufacturing (QRM) prioritizes minimizing lead times and adapts well to high-mix, low-volume production by enabling rapid changeovers and agile workflows. Manufacturers dealing with diverse product mixes and short production runs benefit more from QRM's focus on speed and flexibility.

Implementation Challenges and Solutions

Lean Manufacturing faces implementation challenges such as employee resistance to change and the complexity of waste identification, while Quick Response Manufacturing struggles with supply chain coordination and rapid product customization demands. Solutions for Lean involve comprehensive training programs and continuous improvement culture to overcome resistance and optimize processes. For Quick Response Manufacturing, integrating advanced IT systems and fostering close supplier relationships enable faster response times and flexible production capabilities.

Choosing the Right Strategy for Your Manufacturing Operations

Lean Manufacturing emphasizes waste reduction and continuous improvement to enhance efficiency and lower costs, making it ideal for stable, predictable production environments. Quick Response Manufacturing prioritizes agility and rapid customer response, suitable for markets demanding customization and fast turnaround times. Selecting the right strategy depends on evaluating production volume, product variability, and customer lead time requirements to align operational goals with market demands.

Related Important Terms

Value Stream Mapping (VSM)

Lean Manufacturing utilizes Value Stream Mapping (VSM) to identify and eliminate waste across production processes, enhancing flow efficiency and reducing lead times. Quick Response Manufacturing integrates VSM to rapidly adjust value streams, emphasizing flexibility and responsiveness to customer demand fluctuations.

Takt Time Engineering

Takt Time Engineering in Lean Manufacturing focuses on synchronizing production pace with customer demand to minimize waste and optimize workflow efficiency. Quick Response Manufacturing leverages takt time to accelerate production cycles and enhance responsiveness, reducing lead times while maintaining high product quality.

POLCA (Paired-cell Overlapping Loops of Cards with Authorization)

Lean Manufacturing emphasizes waste reduction and continuous improvement through standardized processes, while Quick Response Manufacturing (QRM) targets lead-time reduction by enhancing shop floor dynamics; POLCA (Paired-cell Overlapping Loops of Cards with Authorization) serves as a critical communication and control tool in QRM, enabling limited WIP and synchronized workflow between paired cells to adapt swiftly to variable demand and reduce bottlenecks. Integrating POLCA within Quick Response Manufacturing frameworks ensures precise work authorization and real-time coordination, optimizing flow in complex job shop environments beyond traditional Lean pull systems.

Flow Cell Design

Flow cell design in Lean Manufacturing emphasizes minimizing waste and maximizing efficiency through continuous, balanced workflows, while Quick Response Manufacturing prioritizes rapid changeover and flexibility within flow cells to accelerate product customization and lead times. Both methodologies use flow cells to optimize production, but Lean centers on waste reduction and steady flow, and Quick Response focuses on responsiveness and adaptability.

Just-in-Time (JIT) Adaptation

Lean Manufacturing emphasizes Just-in-Time (JIT) adaptation by minimizing waste and optimizing production flow to enhance efficiency and reduce inventory costs. Quick Response Manufacturing (QRM) focuses on JIT adaptation through reducing lead times across the entire supply chain, enabling rapid response to customer demand and increased flexibility.

Time-Based Competition

Lean Manufacturing minimizes waste and optimizes workflows to reduce production time, enhancing efficiency through continuous improvement and just-in-time inventory. Quick Response Manufacturing emphasizes rapid product development and delivery by shortening setup times and accelerating production cycles, enabling firms to compete effectively in time-sensitive markets.

Cellular Manufacturing

Cellular Manufacturing in Lean Manufacturing emphasizes waste reduction through organized workstations arranged by product family, enhancing workflow and minimizing lead times. Quick Response Manufacturing applies cellular layouts to rapidly adapt production to customer demand, improving flexibility and reducing inventory levels for just-in-time delivery.

Drum-Buffer-Rope (DBR) Synchronization

Drum-Buffer-Rope (DBR) synchronization in Quick Response Manufacturing (QRM) emphasizes the identification and management of the system's constraint to optimize flow and reduce lead times, contrasting with Lean Manufacturing's focus on waste elimination and continuous flow improvement. QRM's DBR approach strategically controls work-in-process inventory and prioritizes scheduling around the drum (constraint), buffered by time and resources, ensuring rapid response to customer demand in manufacturing environments.

High-Mix Low-Volume (HMLV) Production

Lean Manufacturing emphasizes waste reduction and continuous improvement to optimize High-Mix Low-Volume (HMLV) production by streamlining processes and minimizing inventory. Quick Response Manufacturing (QRM) focuses on reducing lead times and accelerating product flow in HMLV environments, enabling rapid adaptation to customer demands and enhancing overall flexibility.

Systemic Waste Elimination

Lean Manufacturing systematically eliminates waste by identifying and reducing non-value-added activities across production processes, enhancing efficiency and quality. Quick Response Manufacturing accelerates this elimination by integrating rapid feedback loops and flexible operations, minimizing delays and inventory waste to meet customer demand swiftly.

Lean Manufacturing vs Quick Response Manufacturing Infographic

industrydif.com

industrydif.com