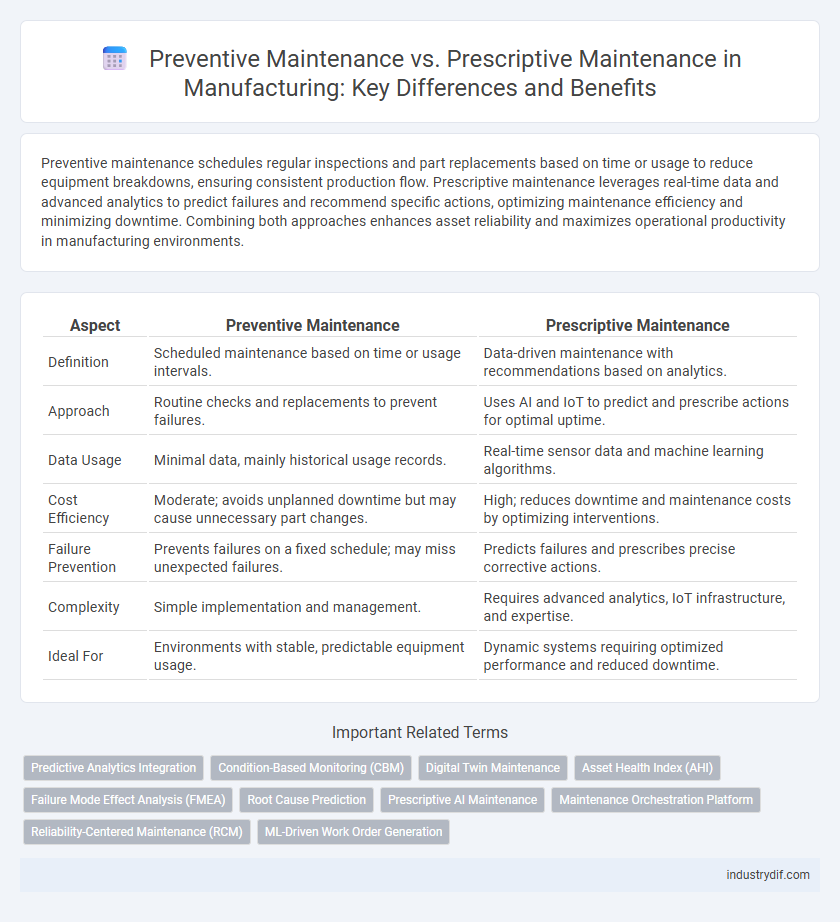

Preventive maintenance schedules regular inspections and part replacements based on time or usage to reduce equipment breakdowns, ensuring consistent production flow. Prescriptive maintenance leverages real-time data and advanced analytics to predict failures and recommend specific actions, optimizing maintenance efficiency and minimizing downtime. Combining both approaches enhances asset reliability and maximizes operational productivity in manufacturing environments.

Table of Comparison

| Aspect | Preventive Maintenance | Prescriptive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals. | Data-driven maintenance with recommendations based on analytics. |

| Approach | Routine checks and replacements to prevent failures. | Uses AI and IoT to predict and prescribe actions for optimal uptime. |

| Data Usage | Minimal data, mainly historical usage records. | Real-time sensor data and machine learning algorithms. |

| Cost Efficiency | Moderate; avoids unplanned downtime but may cause unnecessary part changes. | High; reduces downtime and maintenance costs by optimizing interventions. |

| Failure Prevention | Prevents failures on a fixed schedule; may miss unexpected failures. | Predicts failures and prescribes precise corrective actions. |

| Complexity | Simple implementation and management. | Requires advanced analytics, IoT infrastructure, and expertise. |

| Ideal For | Environments with stable, predictable equipment usage. | Dynamic systems requiring optimized performance and reduced downtime. |

Introduction to Preventive and Prescriptive Maintenance

Preventive maintenance involves scheduled inspections and routine servicing to minimize equipment failures and extend machinery lifespan. Prescriptive maintenance leverages advanced data analytics, machine learning, and real-time sensor data to predict issues and recommend specific corrective actions. Both approaches reduce unplanned downtime, but prescriptive maintenance enhances decision-making by providing actionable insights customized to individual asset conditions.

Key Definitions: Preventive vs Prescriptive Maintenance

Preventive maintenance involves scheduled inspections and routine servicing to prevent equipment failures based on time or usage intervals. Prescriptive maintenance leverages advanced analytics and real-time data to recommend specific actions, optimizing repair timing and resource allocation. Key distinctions center on preventive maintenance's reliance on historical schedules versus prescriptive maintenance's dynamic, data-driven decision-making.

Core Objectives of Preventive Maintenance

Preventive maintenance aims to reduce equipment downtime and extend asset lifespan by scheduling regular inspections and servicing based on time or usage intervals. Its core objectives include identifying potential failures before they occur, ensuring consistent production quality, and minimizing costly unplanned breakdowns. This approach relies on historical data and manufacturer recommendations to maintain optimal operational efficiency.

Principles of Prescriptive Maintenance

Prescriptive maintenance leverages advanced data analytics, machine learning algorithms, and real-time sensor data to provide actionable recommendations that optimize equipment performance and minimize downtime. Unlike preventive maintenance, which follows scheduled intervals, prescriptive maintenance dynamically adjusts maintenance actions based on predictive insights, improving resource allocation and operational efficiency. Core principles include continuous condition monitoring, data-driven decision-making, and automated feedback loops to prevent failures before they occur.

Technology Involved in Both Maintenance Approaches

Preventive maintenance relies on scheduled inspections and routine servicing using sensors and basic diagnostic tools to detect wear or potential failures before breakdowns occur. Prescriptive maintenance integrates advanced technologies such as IoT devices, artificial intelligence, machine learning algorithms, and real-time data analytics to not only predict equipment failures but also recommend specific corrective actions. Machine condition monitoring systems and cloud-based platforms play a crucial role in enabling prescriptive maintenance by providing actionable insights that optimize maintenance schedules and reduce downtime.

Cost Impact: Preventive vs Prescriptive Maintenance

Preventive maintenance typically incurs higher routine costs due to scheduled inspections and part replacements regardless of actual equipment condition, leading to potentially unnecessary downtime and labor expenses. Prescriptive maintenance leverages real-time data and analytics to optimize maintenance timing, significantly reducing unexpected failures and minimizing repair costs by addressing issues only when necessary. The cost impact favors prescriptive maintenance by enhancing resource allocation efficiency, lowering operational expenditures, and improving overall equipment effectiveness (OEE).

Data Requirements and Analysis Techniques

Preventive maintenance relies on scheduled inspections and time-based replacement of parts, using historical data and basic trend analysis to predict failures before they occur. Prescriptive maintenance requires real-time data collection from IoT sensors and advanced analytics such as machine learning algorithms to provide specific recommendations for repairs and optimizations. Data requirements for prescriptive maintenance are more complex, demanding higher volume, variety, and velocity to enable detailed root cause analysis and predictive modeling.

Benefits and Limitations of Each Approach

Preventive maintenance reduces equipment downtime and extends asset life by scheduling regular inspections and servicing based on time or usage, but it can lead to unnecessary maintenance and resource waste. Prescriptive maintenance leverages real-time data and advanced analytics to provide exact maintenance actions, which enhances efficiency and reduces failures but requires substantial investment in IoT sensors and sophisticated AI algorithms. Balancing these approaches depends on production demands, data availability, and cost considerations, ensuring optimal asset performance and minimizing unexpected breakdowns.

Industry Case Studies: Implementation Outcomes

Industry case studies reveal that preventive maintenance reduces unplanned downtime by up to 30% through scheduled inspections and routine repairs, enhancing equipment lifespan and operational efficiency. In contrast, prescriptive maintenance leverages advanced analytics and IoT sensor data to predict failures with over 85% accuracy, enabling targeted interventions that improve uptime by 20% and reduce maintenance costs by 15%. Manufacturers adopting prescriptive maintenance report faster decision-making and higher return on investment compared to traditional preventive approaches.

Choosing the Right Maintenance Strategy for Manufacturing

Selecting the appropriate maintenance strategy in manufacturing hinges on balancing cost efficiency and operational reliability. Preventive maintenance schedules routine inspections and part replacements based on time or usage intervals, reducing unexpected breakdowns. Prescriptive maintenance leverages advanced analytics and IoT data to predict failures and prescribe specific actions, enabling targeted interventions that optimize uptime and reduce unnecessary maintenance expenses.

Related Important Terms

Predictive Analytics Integration

Preventive maintenance schedules routine equipment checks based on fixed intervals, minimizing unexpected breakdowns but often leading to unnecessary downtime, while prescriptive maintenance leverages predictive analytics integration to analyze real-time sensor data, machine learning algorithms, and historical performance trends for optimal, condition-based interventions. Predictive analytics enhances decision-making accuracy by forecasting potential failures and recommending precise corrective actions, improving overall equipment effectiveness (OEE) and reducing maintenance costs in manufacturing environments.

Condition-Based Monitoring (CBM)

Condition-Based Monitoring (CBM) enhances preventive maintenance by using real-time data and sensor analytics to predict equipment failures before they occur, reducing downtime and maintenance costs. Prescriptive maintenance builds on CBM by providing actionable recommendations through AI-driven algorithms that optimize repair schedules and resource allocation, improving overall manufacturing efficiency.

Digital Twin Maintenance

Digital Twin Maintenance leverages real-time data and advanced analytics to enhance Prescriptive Maintenance by predicting equipment failures and recommending precise interventions, outperforming traditional Preventive Maintenance schedules. Integrating Digital Twins enables manufacturers to optimize asset performance, reduce downtime, and extend machinery lifespan through data-driven, condition-based maintenance strategies.

Asset Health Index (AHI)

Preventive Maintenance relies on scheduled inspections and routine servicing to maintain asset reliability, while Prescriptive Maintenance uses advanced analytics and real-time data to optimize interventions based on Asset Health Index (AHI) trends. The Asset Health Index integrates sensor data and operational parameters, enabling Prescriptive Maintenance to precisely predict failures and extend equipment lifespan more effectively than traditional Preventive approaches.

Failure Mode Effect Analysis (FMEA)

Failure Mode Effect Analysis (FMEA) plays a critical role in both preventive and prescriptive maintenance by identifying potential failure modes and their impacts on manufacturing equipment, enabling targeted interventions to reduce downtime. Prescriptive maintenance leverages FMEA data combined with real-time analytics and machine learning to optimize maintenance schedules and prescribe exact actions, surpassing traditional preventive maintenance's reliance on routine intervals.

Root Cause Prediction

Preventive maintenance schedules regular inspections and replacements based on time or usage, reducing unexpected downtime but often lacking precision in addressing underlying issues. Prescriptive maintenance employs advanced analytics and root cause prediction, leveraging real-time data and machine learning to optimize interventions and prevent failures before they occur, enhancing asset reliability and operational efficiency.

Prescriptive AI Maintenance

Prescriptive AI Maintenance leverages advanced data analytics and machine learning algorithms to not only predict equipment failures but also recommend optimized actions, significantly reducing downtime and maintenance costs. This approach surpasses traditional Preventive Maintenance by enabling real-time decision-making and adaptive scheduling tailored to specific machine conditions and operational data.

Maintenance Orchestration Platform

A Maintenance Orchestration Platform leverages real-time data analytics to transition from Preventive Maintenance, which relies on scheduled inspections, to Prescriptive Maintenance that predicts failures and recommends precise actions. This advanced integration minimizes downtime, optimizes resource allocation, and enhances overall equipment effectiveness in manufacturing environments.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) prioritizes Prescriptive Maintenance by leveraging real-time data and advanced analytics to predict failures before they occur, enhancing equipment reliability and reducing unplanned downtime. Unlike traditional Preventive Maintenance, which follows fixed schedules, RCM customizes maintenance tasks based on actual asset condition and operational context, optimizing resource allocation and extending asset lifecycle.

ML-Driven Work Order Generation

ML-driven work order generation in prescriptive maintenance leverages real-time sensor data and advanced algorithms to predict equipment failures and recommend specific corrective actions, optimizing maintenance schedules and minimizing downtime. Preventive maintenance relies on fixed intervals or usage-based triggers, often leading to unnecessary maintenance tasks and higher operational costs compared to the dynamic, data-driven approach of prescriptive maintenance.

Preventive Maintenance vs Prescriptive Maintenance Infographic

industrydif.com

industrydif.com