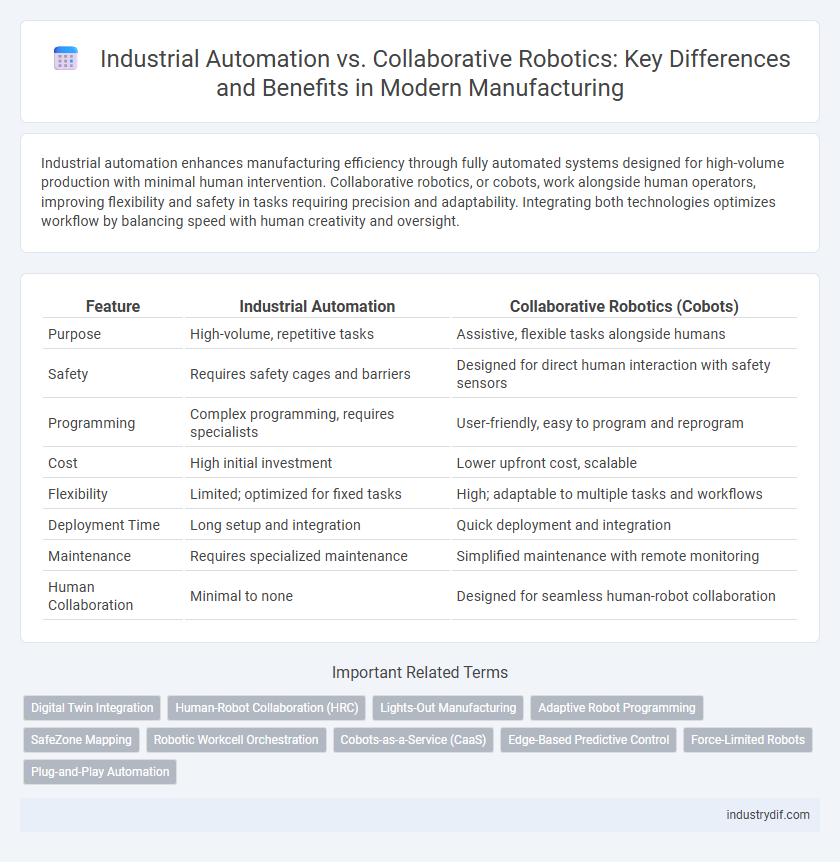

Industrial automation enhances manufacturing efficiency through fully automated systems designed for high-volume production with minimal human intervention. Collaborative robotics, or cobots, work alongside human operators, improving flexibility and safety in tasks requiring precision and adaptability. Integrating both technologies optimizes workflow by balancing speed with human creativity and oversight.

Table of Comparison

| Feature | Industrial Automation | Collaborative Robotics (Cobots) |

|---|---|---|

| Purpose | High-volume, repetitive tasks | Assistive, flexible tasks alongside humans |

| Safety | Requires safety cages and barriers | Designed for direct human interaction with safety sensors |

| Programming | Complex programming, requires specialists | User-friendly, easy to program and reprogram |

| Cost | High initial investment | Lower upfront cost, scalable |

| Flexibility | Limited; optimized for fixed tasks | High; adaptable to multiple tasks and workflows |

| Deployment Time | Long setup and integration | Quick deployment and integration |

| Maintenance | Requires specialized maintenance | Simplified maintenance with remote monitoring |

| Human Collaboration | Minimal to none | Designed for seamless human-robot collaboration |

Introduction to Industrial Automation and Collaborative Robotics

Industrial automation integrates advanced control systems and machinery to streamline manufacturing processes, enhancing precision, efficiency, and scalability. Collaborative robotics, or cobots, are designed to work safely alongside human operators, boosting productivity through shared tasks and adaptive interaction. Both technologies drive Industry 4.0 innovations, reducing downtime and optimizing factory performance.

Definition and Key Features of Industrial Automation

Industrial automation refers to the use of control systems, such as computers or robots, and information technologies to handle different processes and machinery in manufacturing with minimal human intervention. Key features include programmable logic controllers (PLCs), sensors, actuators, and SCADA (Supervisory Control and Data Acquisition) systems, enabling high precision, consistency, and efficiency in production lines. It emphasizes large-scale automation for repetitive tasks, enhancing productivity and reducing operational costs.

Overview of Collaborative Robotics (Cobots)

Collaborative robotics, or cobots, are designed to work safely alongside human operators in manufacturing environments, enhancing productivity without extensive safety barriers. Unlike traditional industrial automation, cobots are equipped with advanced sensors and AI capabilities that allow real-time interaction and adaptive task execution. This seamless human-robot collaboration reduces cycle times, increases flexibility, and supports complex assembly processes in smart factories.

Core Differences Between Industrial Automation and Cobots

Industrial automation involves fully autonomous machines designed for high-volume, repetitive tasks requiring minimal human intervention, whereas collaborative robotics (cobots) are engineered to work safely alongside human operators, enhancing flexibility and adaptability on the factory floor. Industrial automation systems prioritize speed, precision, and continuous operation, often enclosed for safety, while cobots feature advanced sensors and easy programmability for dynamic interactions in mixed environments. Core differences include the degree of human-robot interaction, deployment complexity, and targeted applications, with industrial automation suited for standardized mass production and cobots driving innovation in customizable small-batch manufacturing.

Applications of Industrial Automation in Manufacturing

Industrial automation in manufacturing enhances production efficiency through programmable logic controllers (PLCs), robotics arms, and conveyor systems that perform repetitive tasks with high precision. Applications include assembly line automation, quality control inspection using machine vision, and real-time monitoring of production processes via SCADA systems. These technologies reduce human error, increase throughput, and optimize operational costs in automotive, electronics, and consumer goods manufacturing industries.

Collaborative Robotics Use Cases in Modern Factories

Collaborative robotics in modern factories excel in tasks such as assembly, quality inspection, and material handling, enabling seamless human-robot interaction on the production floor. These robots adapt to dynamic environments, enhancing precision and efficiency without extensive safety barriers, which reduces downtime and operational costs. Industrial sectors including automotive, electronics, and consumer goods leverage collaborative robots to increase flexibility and meet customized production demands.

Safety Considerations: Automation vs. Cobots

Industrial automation systems typically operate within segregated environments to ensure operator safety by minimizing human interaction with machines. Collaborative robots (cobots) are designed with advanced sensors and force-limiting technologies that enable safe human-robot collaboration in shared workspaces. Safety standards such as ISO 10218 and ISO/TS 15066 provide guidelines specifically addressing risk assessment and mitigation for both traditional industrial automation and cobotic applications.

Flexibility and Adaptability in Manufacturing Processes

Industrial automation systems excel in high-volume, repetitive manufacturing tasks by providing consistent precision and speed, but they often lack flexibility when adapting to product changes or customization. Collaborative robotics, or cobots, enhance flexibility and adaptability by working alongside human operators and easily reprogramming for varied tasks, making them ideal for dynamic production environments. This adaptability reduces downtime and supports just-in-time manufacturing, increasing overall efficiency in modern manufacturing processes.

Cost Implications and ROI Analysis

Industrial automation typically involves high upfront capital investment in fixed machinery and systems designed for large-scale production, resulting in longer ROI periods. Collaborative robotics (cobots) offer lower initial costs and greater flexibility, enabling faster deployment and quicker returns in diverse manufacturing settings. Evaluating total cost of ownership and productivity gains is crucial for manufacturers to optimize investment decisions between rigid automation and adaptive collaborative robots.

Future Trends in Automation and Collaborative Robotics

Future trends in manufacturing highlight the integration of advanced industrial automation systems with collaborative robotics (cobots) to enhance productivity and flexibility on the production floor. Industrial automation leverages AI-driven predictive maintenance and real-time data analytics, while collaborative robotics advances in sensor technology and machine learning enable safer and more intuitive human-robot interaction. The convergence of these technologies drives smart factories, optimizing workflow efficiency and enabling adaptive manufacturing processes that respond dynamically to market demands.

Related Important Terms

Digital Twin Integration

Industrial automation leverages Digital Twin integration to create virtual replicas of manufacturing systems, enabling precise monitoring and predictive maintenance, while collaborative robotics incorporate Digital Twins for real-time interaction and adaptive task execution alongside human workers. Digital Twin-driven control and simulation enhance operational efficiency and safety by synchronizing automated machinery and collaborative robots within smart factory environments.

Human-Robot Collaboration (HRC)

Industrial automation enhances manufacturing efficiency by integrating programmable machines that operate independently, while collaborative robotics (cobots) prioritize Human-Robot Collaboration (HRC) by enabling safe, flexible interactions between humans and robots on the production floor. HRC improves workplace ergonomics and productivity by combining human intelligence and dexterity with robotic precision and consistency.

Lights-Out Manufacturing

Industrial automation employs fully automated systems to enable lights-out manufacturing, minimizing human intervention and maximizing operational efficiency. Collaborative robotics, while designed to work alongside humans, typically require some level of human presence, making them less optimal for completely unattended production environments.

Adaptive Robot Programming

Adaptive robot programming enhances industrial automation by enabling machines to independently adjust to complex manufacturing tasks, reducing downtime and increasing precision. Collaborative robotics integrate adaptive algorithms to safely work alongside human operators, improving flexibility and efficiency in dynamic production environments.

SafeZone Mapping

Industrial automation employs rigid SafeZone mapping to segregate human workers from machines, minimizing risk through fixed boundaries and predefined zones. Collaborative robotics utilizes dynamic SafeZone mapping, allowing robots to sense and adapt to human presence in real time, enhancing flexibility and safety in shared workspaces.

Robotic Workcell Orchestration

Industrial automation utilizes highly programmed, standalone robotic systems to maximize efficiency and precision in repetitive manufacturing tasks, while collaborative robotics emphasizes human-robot interaction for flexible, adaptive production environments. Robotic workcell orchestration integrates multiple robots and automation devices within a shared workspace, optimizing task coordination, cycle times, and safety protocols to enhance overall manufacturing throughput.

Cobots-as-a-Service (CaaS)

Cobots-as-a-Service (CaaS) offers flexible deployment of collaborative robots in manufacturing, enabling seamless integration with existing industrial automation systems and reducing upfront capital expenditures. This model enhances scalability and operational efficiency by providing on-demand access to adaptive, user-friendly robots that work safely alongside human operators.

Edge-Based Predictive Control

Edge-based predictive control enhances industrial automation by enabling real-time data processing at the device level, reducing latency and improving system responsiveness. Collaborative robotics leverage this technology to adapt dynamically to changing environments, optimizing manufacturing efficiency and safety through precise, predictive adjustments.

Force-Limited Robots

Force-limited robots in industrial automation enhance safety by limiting the force applied during operations, reducing the risk of injury and equipment damage. Collaborative robotics leverage these force-sensitive mechanisms to allow seamless human-robot interaction, enabling flexible manufacturing processes without extensive safety barriers.

Plug-and-Play Automation

Plug-and-play automation streamlines manufacturing by enabling industrial automation systems to be quickly integrated with minimal programming, reducing setup times and increasing operational efficiency. Collaborative robotics enhance this by offering user-friendly interfaces and safety features that allow seamless human-robot interaction, facilitating flexible, adaptive production lines without extensive reconfiguration.

Industrial Automation vs Collaborative Robotics Infographic

industrydif.com

industrydif.com