ERP systems centralize business data and streamline operations by integrating finance, procurement, and supply chain management, offering a comprehensive overview of manufacturing workflows. Smart manufacturing platforms leverage real-time data, IoT devices, and AI analytics to enhance process optimization, predictive maintenance, and adaptive production strategies. Combining ERP systems with smart manufacturing platforms creates a synergistic environment that boosts operational efficiency, reduces downtime, and supports data-driven decision-making.

Table of Comparison

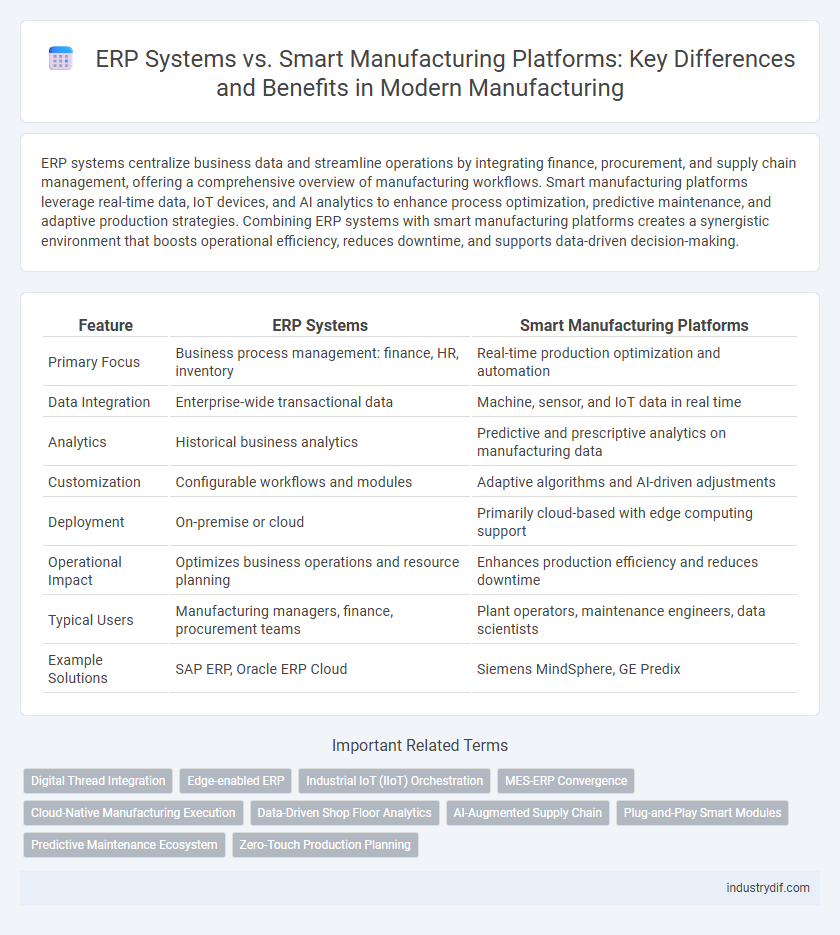

| Feature | ERP Systems | Smart Manufacturing Platforms |

|---|---|---|

| Primary Focus | Business process management: finance, HR, inventory | Real-time production optimization and automation |

| Data Integration | Enterprise-wide transactional data | Machine, sensor, and IoT data in real time |

| Analytics | Historical business analytics | Predictive and prescriptive analytics on manufacturing data |

| Customization | Configurable workflows and modules | Adaptive algorithms and AI-driven adjustments |

| Deployment | On-premise or cloud | Primarily cloud-based with edge computing support |

| Operational Impact | Optimizes business operations and resource planning | Enhances production efficiency and reduces downtime |

| Typical Users | Manufacturing managers, finance, procurement teams | Plant operators, maintenance engineers, data scientists |

| Example Solutions | SAP ERP, Oracle ERP Cloud | Siemens MindSphere, GE Predix |

Introduction to ERP Systems and Smart Manufacturing Platforms

ERP systems integrate core manufacturing processes such as inventory management, production planning, and financial accounting into a centralized software platform to enhance operational efficiency and data accuracy. Smart manufacturing platforms leverage advanced technologies like IoT sensors, AI analytics, and cloud computing to enable real-time monitoring, predictive maintenance, and adaptive production workflows. Both systems serve to optimize manufacturing operations, but smart manufacturing platforms offer more dynamic, data-driven capabilities that support Industry 4.0 initiatives.

Core Functionalities: ERP Systems vs Smart Manufacturing Platforms

ERP systems primarily focus on integrating key business processes such as finance, procurement, inventory management, and human resources to streamline operations and improve resource planning. Smart manufacturing platforms emphasize real-time data collection, advanced analytics, machine-to-machine communication, and automation to optimize production efficiency and enable predictive maintenance. Both systems aim to enhance operational performance, but ERP systems offer broad organizational management while smart manufacturing platforms provide detailed shop floor intelligence.

Integration Capabilities: Seamless Data Flow or Silos?

ERP systems often struggle with integration due to their rigid architectures, resulting in data silos that hinder real-time decision-making in manufacturing environments. In contrast, smart manufacturing platforms leverage advanced IoT connectivity and open APIs to enable seamless data flow across production lines, supply chains, and enterprise systems. This integration capability enhances visibility, agility, and operational efficiency, driving smarter manufacturing outcomes.

Real-Time Data Processing and Decision-Making

ERP systems primarily manage enterprise-wide processes and data integration, but often face latency issues in real-time data processing. Smart manufacturing platforms leverage IoT sensors and edge computing to deliver instantaneous insights and enable dynamic decision-making on the production floor. This real-time data processing enhances operational efficiency, predictive maintenance, and adaptive control, outperforming traditional ERP capabilities in manufacturing environments.

Flexibility and Scalability in Manufacturing Operations

ERP systems streamline manufacturing operations by integrating core processes like inventory, procurement, and production planning, offering structured scalability suited for established workflows. Smart manufacturing platforms provide superior flexibility with real-time data analytics, IoT integration, and adaptive automation, enabling dynamic adjustments to production lines and rapid scaling in response to market demands. Manufacturers seeking agile, scalable solutions benefit from smart platforms' ability to quickly incorporate new technologies and optimize operations beyond traditional ERP capabilities.

Implementation Complexity and Timeframes

ERP systems typically involve extensive implementation phases, often requiring months to years to fully integrate with existing manufacturing processes due to their broad scope and customization needs. Smart manufacturing platforms offer more agile deployment, leveraging modular and cloud-based technologies which significantly reduce implementation timeframes, often to weeks or a few months. The complexity in ERP arises from deep integration across departments, whereas smart platforms focus on real-time data analytics and equipment connectivity, simplifying implementation for digital manufacturing initiatives.

Cost Considerations: Upfront and Ongoing Investments

ERP systems require significant upfront costs for software licenses, customization, and implementation, with ongoing expenses including maintenance, updates, and support services. Smart manufacturing platforms often involve modular investments that scale with operational needs, potentially reducing initial capital outlay but incurring continuous data analytics, IoT device integration, and cloud service fees. Evaluating total cost of ownership requires manufacturing firms to balance immediate financial commitments against long-term benefits such as process optimization and predictive maintenance enabled by smart technologies.

Customization and Industry-Specific Adaptability

ERP systems offer extensive customization options tailored to various manufacturing processes, enabling seamless integration with existing workflows and legacy systems. Smart manufacturing platforms prioritize industry-specific adaptability by leveraging advanced technologies like IoT, AI, and real-time analytics to optimize production efficiency and quality control. Both solutions enhance operational agility, but smart manufacturing platforms provide more dynamic adjustments to changing industry demands through modular and scalable architectures.

Impact on Workforce and Change Management

ERP systems streamline workforce management by automating routine tasks and centralizing data, but often require extensive change management due to rigid workflows and user resistance. Smart manufacturing platforms enhance workforce adaptability through real-time data analytics, IoT integration, and AI-driven decision support, fostering a culture of continuous learning and innovation. Transitioning to smart manufacturing demands proactive change management strategies focusing on skill development and employee engagement to maximize workforce productivity and acceptance.

Future Trends: The Convergence of ERP and Smart Manufacturing

The convergence of ERP systems and smart manufacturing platforms is driving the future of industrial automation by integrating real-time data analytics with enterprise resource management for enhanced decision-making and operational efficiency. Advanced ERP solutions increasingly incorporate IoT connectivity, AI-driven predictive maintenance, and digital twin technologies, facilitating seamless communication across supply chains and production lines. This integration enables manufacturers to achieve agile responsiveness, reduce downtime, and optimize resource allocation, positioning smart manufacturing as the cornerstone of Industry 4.0 innovation.

Related Important Terms

Digital Thread Integration

ERP systems centralize enterprise data and processes, ensuring resource planning and operational efficiency, while smart manufacturing platforms leverage digital thread integration to connect design, production, and supply chain data in real time. This seamless data flow enhances traceability, reduces production errors, and accelerates decision-making through synchronized digital continuity across the manufacturing lifecycle.

Edge-enabled ERP

Edge-enabled ERP systems integrate real-time data processing at the manufacturing floor, enhancing operational efficiency and reducing latency compared to traditional cloud-based ERP solutions. Smart manufacturing platforms leverage IoT and AI for predictive maintenance and adaptive workflows, but edge-enabled ERP combines these capabilities with enterprise resource planning for seamless data synchronization across production and business processes.

Industrial IoT (IIoT) Orchestration

ERP systems primarily manage enterprise resources and internal processes, while smart manufacturing platforms leverage Industrial IoT (IIoT) orchestration to integrate real-time data from connected devices, enabling advanced automation and predictive maintenance. IIoT orchestration enhances operational efficiency by synchronizing sensor networks, machine data, and analytics on smart manufacturing platforms beyond the capabilities of traditional ERP solutions.

MES-ERP Convergence

MES-ERP convergence integrates Manufacturing Execution Systems with Enterprise Resource Planning to enhance real-time data exchange, streamline production workflows, and improve decision-making accuracy in smart manufacturing environments. This integration reduces operational silos, boosts production efficiency by synchronizing shop floor execution with enterprise-level planning, and supports adaptive manufacturing processes driven by Industry 4.0 technologies.

Cloud-Native Manufacturing Execution

Cloud-native manufacturing execution systems (MES) integrated within ERP platforms streamline production workflows by enabling real-time data analytics, flexible scalability, and seamless interoperability across supply chain operations. Smart manufacturing platforms leverage these cloud-native MES capabilities to enhance process automation, predictive maintenance, and adaptive scheduling, driving higher efficiency and reduced operational costs.

Data-Driven Shop Floor Analytics

ERP systems primarily manage enterprise-wide resources and operations but lack real-time data integration essential for dynamic shop floor analytics. Smart manufacturing platforms enable data-driven insights by leveraging IoT, machine learning, and edge computing to optimize production efficiency and predictive maintenance on the shop floor.

AI-Augmented Supply Chain

ERP systems centralize data management but often lack real-time AI capabilities essential for optimizing dynamic supply chain operations. Smart Manufacturing Platforms leverage AI-augmented analytics and machine learning algorithms to enhance supply chain visibility, predictive maintenance, and adaptive decision-making, driving efficiency and responsiveness.

Plug-and-Play Smart Modules

Plug-and-play smart modules in manufacturing enable ERP systems to seamlessly integrate real-time data analytics, machine learning, and IoT connectivity, enhancing operational efficiency and reducing downtime. These modules facilitate modular scalability and rapid deployment, outperforming traditional ERP systems that often require complex customization and longer implementation periods.

Predictive Maintenance Ecosystem

ERP systems centralize data management but often lack advanced predictive maintenance capabilities, limiting real-time equipment monitoring and failure prediction. Smart manufacturing platforms integrate IoT sensors, AI algorithms, and machine learning to create a dynamic predictive maintenance ecosystem that reduces downtime and extends asset life.

Zero-Touch Production Planning

ERP systems offer centralized data management but often lack real-time adaptability for Zero-Touch Production Planning, whereas Smart Manufacturing Platforms leverage IoT and AI to enable fully automated, responsive production workflows. Integrating machine learning algorithms and sensor data, these platforms optimize scheduling, reduce manual intervention, and drive higher operational efficiency through continuous process refinement.

ERP Systems vs Smart Manufacturing Platforms Infographic

industrydif.com

industrydif.com