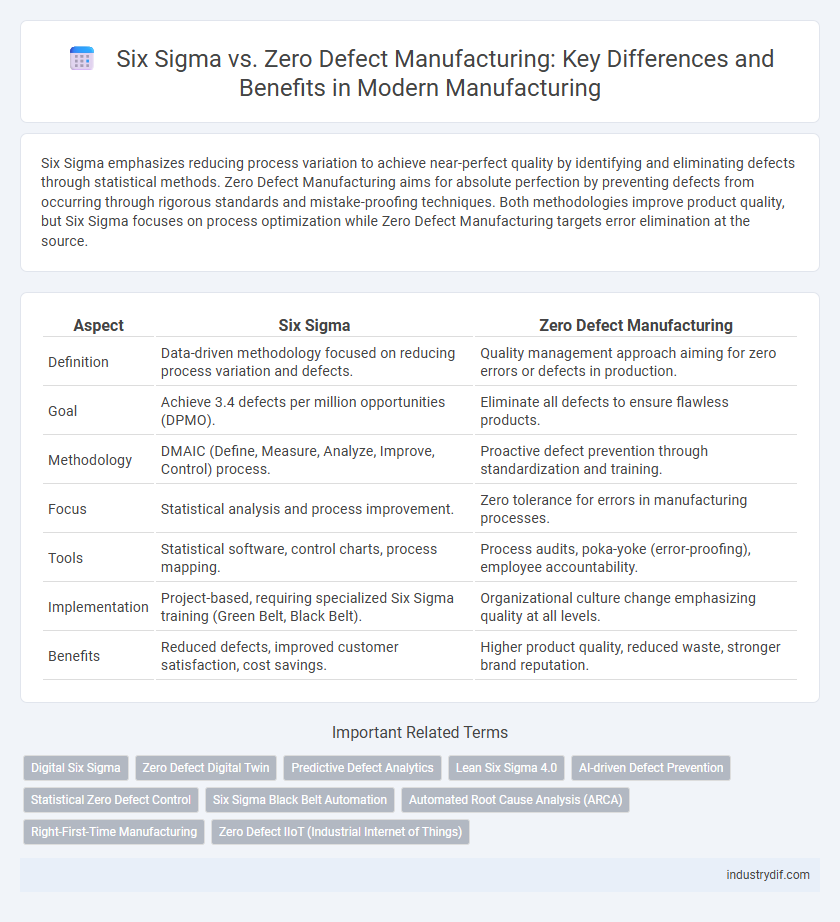

Six Sigma emphasizes reducing process variation to achieve near-perfect quality by identifying and eliminating defects through statistical methods. Zero Defect Manufacturing aims for absolute perfection by preventing defects from occurring through rigorous standards and mistake-proofing techniques. Both methodologies improve product quality, but Six Sigma focuses on process optimization while Zero Defect Manufacturing targets error elimination at the source.

Table of Comparison

| Aspect | Six Sigma | Zero Defect Manufacturing |

|---|---|---|

| Definition | Data-driven methodology focused on reducing process variation and defects. | Quality management approach aiming for zero errors or defects in production. |

| Goal | Achieve 3.4 defects per million opportunities (DPMO). | Eliminate all defects to ensure flawless products. |

| Methodology | DMAIC (Define, Measure, Analyze, Improve, Control) process. | Proactive defect prevention through standardization and training. |

| Focus | Statistical analysis and process improvement. | Zero tolerance for errors in manufacturing processes. |

| Tools | Statistical software, control charts, process mapping. | Process audits, poka-yoke (error-proofing), employee accountability. |

| Implementation | Project-based, requiring specialized Six Sigma training (Green Belt, Black Belt). | Organizational culture change emphasizing quality at all levels. |

| Benefits | Reduced defects, improved customer satisfaction, cost savings. | Higher product quality, reduced waste, stronger brand reputation. |

Introduction to Six Sigma and Zero Defect Manufacturing

Six Sigma is a data-driven methodology aimed at reducing process variation and defects by using statistical tools to achieve near-perfect quality, typically targeting 3.4 defects per million opportunities. Zero Defect Manufacturing emphasizes defect prevention by promoting a culture of doing things right the first time, striving for absolute elimination of errors rather than just reduction. Both approaches focus on improving product quality and operational efficiency, but Six Sigma relies heavily on measurement and analysis, while Zero Defect Manufacturing centers on proactive error-proofing and employee involvement.

Core Principles of Six Sigma

Six Sigma emphasizes reducing process variation and improving quality through a data-driven approach and the DMAIC (Define, Measure, Analyze, Improve, Control) methodology, targeting a defect rate below 3.4 per million opportunities. Core principles include critical focus on customer requirements, process management, statistical analysis, and continuous improvement to achieve near-perfect outputs. Zero Defect Manufacturing prioritizes error prevention and the mindset of doing things right the first time but lacks the structured statistical tools embedded in Six Sigma for systematic defect reduction.

Key Concepts Behind Zero Defect Manufacturing

Zero Defect Manufacturing focuses on the principle of defect prevention by designing processes that aim for zero errors through stringent quality control and employee accountability. It emphasizes defect elimination at the source by integrating error-proofing techniques (poka-yoke) and continuous process monitoring to ensure products meet exact specifications consistently. Unlike Six Sigma, which targets reduction of variation and defects statistically, Zero Defect Manufacturing insists on perfection by fostering a culture of quality awareness and proactive error prevention.

Process Improvement Methodologies: DMAIC vs Zero Defect Focus

Six Sigma utilizes the DMAIC (Define, Measure, Analyze, Improve, Control) framework to systematically reduce process variation and improve quality through data-driven decision making. Zero Defect Manufacturing emphasizes a proactive culture aiming for flawless production by embedding defect prevention strategies and continuous error elimination. While DMAIC targets incremental enhancements by analyzing root causes, Zero Defect focuses on designing processes that inherently prevent defects from occurring.

Statistical Analysis in Six Sigma vs Error Prevention in Zero Defect

Six Sigma utilizes rigorous statistical analysis, including DMAIC methodology and control charts, to identify and eliminate process variation, driving quality improvement through data-driven decision making. In contrast, Zero Defect Manufacturing emphasizes proactive error prevention strategies, such as mistake-proofing (poka-yoke) and continuous employee training, to achieve defect-free production at the source. The statistical foundation of Six Sigma enables measurable process capability enhancement, while Zero Defect focuses on ingraining quality into every step to prevent defects before they occur.

Implementation Strategies in Modern Manufacturing

Six Sigma implementation in modern manufacturing relies on data-driven methods such as DMAIC (Define, Measure, Analyze, Improve, Control) to reduce process variation and enhance quality control. Zero Defect Manufacturing emphasizes error prevention through robust process design and employee training to achieve near-perfect product quality. Integrating Six Sigma's analytical tools with Zero Defect's proactive mindset fosters continuous improvement and operational excellence in manufacturing facilities.

Measuring Success: Metrics and KPIs

Six Sigma measures success primarily through defect reduction rates and process capability indices such as Cp and Cpk, focusing on statistical control and variation minimization. Zero Defect Manufacturing tracks success using the Defects Per Million Opportunities (DPMO) and First Pass Yield (FPY), emphasizing absolute defect elimination and error-proofing. Both methodologies rely on Key Performance Indicators (KPIs) like customer satisfaction scores and cycle time improvements to evaluate process efficiency and quality enhancement.

Cost Implications and ROI Comparison

Six Sigma reduces manufacturing costs by minimizing process variation and defects, typically delivering an ROI of 4 to 6 times the initial investment through improved yield and quality. Zero Defect Manufacturing emphasizes the elimination of defects at every stage, often requiring higher upfront costs for rigorous training and inspection but resulting in long-term savings by preventing rework and warranty claims. Comparing ROI, Six Sigma provides faster financial returns through measurable improvements, while Zero Defect Manufacturing achieves sustainable cost reduction with a focus on defect prevention and customer satisfaction.

Challenges and Limitations of Both Approaches

Six Sigma faces challenges such as high implementation costs, complex statistical tools that require extensive training, and potential resistance from employees due to its data-driven rigor. Zero Defect Manufacturing struggles with the unrealistic expectation of flawless production, leading to increased pressure on employees and increased inspection costs. Both methodologies encounter limitations in adapting to dynamic manufacturing environments where variability and human error cannot be entirely eliminated.

Choosing the Right Approach for Your Manufacturing Operations

Six Sigma prioritizes reducing process variation and defects through data-driven methodologies, aiming for 3.4 defects per million opportunities, while Zero Defect Manufacturing emphasizes achieving flawless production by preventing errors from the outset. Selecting the right approach depends on your operational goals, complexity of processes, and quality standards; Six Sigma is ideal for continuous improvement in complex systems, whereas Zero Defect focuses on error prevention in highly standardized environments. Integrating elements of both can optimize quality, reduce costs, and enhance customer satisfaction in diverse manufacturing settings.

Related Important Terms

Digital Six Sigma

Digital Six Sigma leverages advanced data analytics and real-time monitoring to enhance process control and reduce variation, driving continuous quality improvements in manufacturing. Zero Defect Manufacturing aims for flawless production by integrating rigorous inspection and error-proofing techniques, but Digital Six Sigma's data-driven approach provides predictive insights that prevent defects before they occur.

Zero Defect Digital Twin

Zero Defect Digital Twin technology integrates real-time manufacturing data with digital simulations to predict and eliminate defects, surpassing traditional Six Sigma methods by enabling proactive quality control and continuous process optimization. This approach reduces variability and enhances product reliability through virtual testing and immediate feedback loops, driving zero-defect outcomes in complex production environments.

Predictive Defect Analytics

Six Sigma leverages statistical methods to reduce process variations and defects by identifying root causes, while Zero Defect Manufacturing aims for flawless production through strict quality standards and continuous improvement. Predictive Defect Analytics enhances both methodologies by utilizing data-driven models and machine learning to forecast potential defects, enabling proactive interventions that minimize waste and increase manufacturing efficiency.

Lean Six Sigma 4.0

Lean Six Sigma 4.0 integrates advanced data analytics and Industry 4.0 technologies to enhance process optimization beyond traditional Six Sigma and Zero Defect Manufacturing by targeting both quality improvement and waste reduction simultaneously. This approach leverages real-time data from IoT devices and AI-driven insights to drive continuous improvement, significantly reducing defects and operational costs in manufacturing environments.

AI-driven Defect Prevention

AI-driven defect prevention in Six Sigma leverages advanced data analytics and machine learning algorithms to identify root causes and minimize variability in manufacturing processes, boosting quality control and process efficiency. Zero Defect Manufacturing integrates AI to achieve near-perfect production by real-time defect detection and predictive maintenance, dramatically reducing waste and operational costs.

Statistical Zero Defect Control

Statistical Zero Defect Control in manufacturing emphasizes using data-driven techniques to identify and eliminate defects, aiming for near-perfect production quality by minimizing variation and process errors. Unlike Six Sigma, which targets reducing defects to 3.4 per million opportunities through DMAIC methodology, Zero Defect Manufacturing seeks absolute defect-free outcomes by applying rigorous statistical process controls and continuous monitoring.

Six Sigma Black Belt Automation

Six Sigma Black Belt Automation focuses on minimizing process variation and defects through data-driven methodologies and advanced automation technologies, achieving near-perfect quality levels. Zero Defect Manufacturing aims for flawless products but lacks the structured statistical tools and automation integration inherent in Six Sigma Black Belt strategies.

Automated Root Cause Analysis (ARCA)

Automated Root Cause Analysis (ARCA) enhances both Six Sigma and Zero Defect Manufacturing by rapidly identifying process deviations through advanced data analytics and machine learning algorithms. ARCA enables real-time error detection and correction, significantly reducing defects and improving process consistency in manufacturing operations.

Right-First-Time Manufacturing

Six Sigma emphasizes reducing process variation to achieve near-perfect quality through statistical methods, while Zero Defect Manufacturing targets eliminating defects completely by focusing on error prevention and employee accountability. Right-First-Time Manufacturing aligns with both approaches by prioritizing defect-free production from the start, thereby minimizing rework and enhancing overall efficiency.

Zero Defect IIoT (Industrial Internet of Things)

Zero Defect Manufacturing leverages IIoT technologies to achieve real-time quality monitoring and predictive maintenance, significantly reducing defect rates by integrating sensors, data analytics, and automated control systems on the production floor. This contrasts with traditional Six Sigma methodologies by emphasizing continuous, sensor-driven feedback loops that enable immediate corrective actions and minimize variation without extensive human intervention.

Six Sigma vs Zero Defect Manufacturing Infographic

industrydif.com

industrydif.com