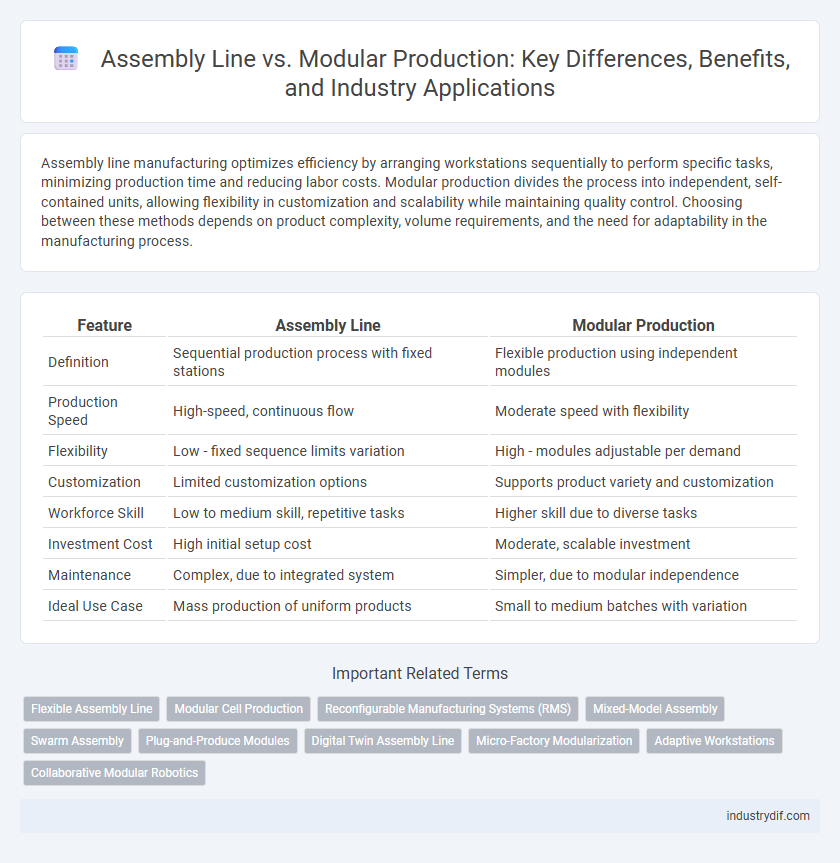

Assembly line manufacturing optimizes efficiency by arranging workstations sequentially to perform specific tasks, minimizing production time and reducing labor costs. Modular production divides the process into independent, self-contained units, allowing flexibility in customization and scalability while maintaining quality control. Choosing between these methods depends on product complexity, volume requirements, and the need for adaptability in the manufacturing process.

Table of Comparison

| Feature | Assembly Line | Modular Production |

|---|---|---|

| Definition | Sequential production process with fixed stations | Flexible production using independent modules |

| Production Speed | High-speed, continuous flow | Moderate speed with flexibility |

| Flexibility | Low - fixed sequence limits variation | High - modules adjustable per demand |

| Customization | Limited customization options | Supports product variety and customization |

| Workforce Skill | Low to medium skill, repetitive tasks | Higher skill due to diverse tasks |

| Investment Cost | High initial setup cost | Moderate, scalable investment |

| Maintenance | Complex, due to integrated system | Simpler, due to modular independence |

| Ideal Use Case | Mass production of uniform products | Small to medium batches with variation |

Overview of Assembly Line Production

Assembly line production streamlines manufacturing by moving products sequentially through fixed workstations, enabling high-volume output with consistent quality. This process reduces production time and labor costs by breaking down tasks into specialized, repetitive steps. Efficiency gains from assembly lines are critical for industries like automotive and electronics, where speed and uniformity drive competitive advantage.

Understanding Modular Production Systems

Modular production systems enable flexible manufacturing by dividing processes into interchangeable units, allowing customization and scalability unlike traditional assembly lines that follow fixed sequences. These systems improve efficiency through parallel processing and reduce downtime by isolating faults within specific modules. Integrating modular production enhances adaptation to changing market demands and supports product variety without extensive retooling.

Key Differences Between Assembly Line and Modular Production

Assembly line production involves a sequential workflow where products move step-by-step through fixed stations, optimizing high-volume manufacturing with repetitive tasks. Modular production divides manufacturing into independent, self-contained units that can be customized and reconfigured, enhancing flexibility and rapid adaptation to design changes. The key difference lies in assembly lines prioritizing efficiency and standardization, while modular production emphasizes adaptability and product variation.

Efficiency and Productivity Comparison

Assembly line production offers high efficiency through standardized, repetitive tasks that minimize transition times and maximize output speed. Modular production enhances productivity by enabling flexible assembly of distinct units, allowing for customization and easier scalability without halting the entire process. Comparing the two, assembly lines excel in mass production of uniform products, while modular systems optimize resource utilization and adaptability in diverse manufacturing environments.

Flexibility in Manufacturing Processes

Assembly line manufacturing offers high efficiency through standardized tasks but limits flexibility due to its rigid, sequential workflow. Modular production enhances flexibility by allowing independent modules to be reconfigured or replaced without disrupting the entire process. This adaptability supports customized products and rapid changes in production volume, making it ideal for dynamic market demands.

Impact on Product Customization

Assembly line production standardizes processes, limiting product customization due to its focus on high-volume, uniform output. Modular production enhances flexibility by allowing individual modules to be customized independently, enabling tailored products without compromising efficiency. This approach accelerates responsiveness to market demands and supports a wider range of product variations.

Labor Requirements and Workforce Skills

Assembly line manufacturing demands a workforce with specialized, repetitive skills focused on efficiency and speed, often requiring minimal cross-training. Modular production emphasizes versatile employees with broader skill sets who can manage multiple tasks and adapt to different modules, enhancing flexibility. Labor requirements in modular systems tend to be higher in terms of skill level but lower in volume compared to the more labor-intensive, narrowly focused assembly lines.

Cost Implications and ROI Analysis

Assembly line manufacturing typically demands high initial capital investment due to specialized equipment and infrastructure but offers lower per-unit costs through economies of scale, enhancing ROI over large production volumes. Modular production incurs higher variable costs stemming from flexible, interchangeable components and setup changes, yet reduces downtime and allows quicker adaptation to market demand, potentially improving ROI in dynamic or customized manufacturing environments. Cost implications vary significantly by product complexity and volume, making ROI analysis crucial to select the optimal production approach aligned with business objectives.

Quality Control in Assembly Line vs Modular Production

Assembly line production enables consistent quality control through standardized processes and repetitive tasks, minimizing variability and defects. Modular production enhances quality management by allowing individual modules to be tested and inspected independently before final assembly, facilitating early detection and correction of issues. Both methods require rigorous quality checkpoints, but modular production provides greater flexibility in isolating and addressing specific component faults.

Future Trends in Manufacturing: Modularization vs Traditional Methods

Modular production is rapidly gaining traction over traditional assembly lines due to its enhanced flexibility, scalability, and reduced downtime in manufacturing processes. Future trends indicate a shift towards modular systems integrated with Industry 4.0 technologies such as IoT, AI, and robotics, enabling real-time customization and efficient resource utilization. This evolution supports mass customization and sustainable manufacturing, positioning modular production as a key driver of innovation in next-generation industrial practices.

Related Important Terms

Flexible Assembly Line

Flexible assembly lines enhance manufacturing efficiency by allowing rapid reconfiguration to accommodate diverse product variations without extensive downtime, contrasting modular production which emphasizes discrete, independently built units. This adaptability supports just-in-time inventory and mass customization, optimizing resource utilization and reducing lead times in complex manufacturing environments.

Modular Cell Production

Modular cell production enhances manufacturing flexibility and efficiency by organizing workstations into independent, self-contained units that complete entire product components, reducing lead times and minimizing waste. This system allows for rapid adaptation to design changes and customization, outperforming traditional assembly line methods in responsiveness and scalability.

Reconfigurable Manufacturing Systems (RMS)

Reconfigurable Manufacturing Systems (RMS) combine the continuous flow efficiency of Assembly Line production with the flexibility of Modular Production, enabling rapid adaptation to product changes and volume variations. RMS optimize manufacturing by incorporating modular platforms that can be restructured quickly, reducing downtime and enhancing customization in highly dynamic markets.

Mixed-Model Assembly

Mixed-model assembly integrates multiple product variants on a single assembly line, enhancing flexibility and reducing changeover time compared to traditional dedicated lines. This approach optimizes production efficiency and inventory management by allowing simultaneous processing of diverse product models within modular production systems.

Swarm Assembly

Swarm assembly in manufacturing leverages decentralized, autonomous robots collaborating seamlessly on the assembly line to enhance flexibility, reduce cycle times, and improve product customization compared to traditional modular production. This approach enables dynamic task distribution and real-time adaptation to variations, driving higher efficiency and scalability in complex manufacturing environments.

Plug-and-Produce Modules

Plug-and-produce modules in modular production enable rapid reconfiguration and scalability of assembly lines, significantly reducing downtime and increasing manufacturing flexibility. Unlike traditional fixed assembly lines, these modules integrate advanced automation and IoT connectivity to optimize workflow and facilitate seamless adaptation to product variations.

Digital Twin Assembly Line

Digital Twin Assembly Line technology enables real-time simulation and optimization of manufacturing processes, significantly enhancing efficiency and reducing downtime compared to traditional Modular Production methods. Integrating IoT sensors and advanced analytics, Digital Twins provide precise digital replicas of assembly lines, facilitating predictive maintenance and adaptive control in complex manufacturing environments.

Micro-Factory Modularization

Micro-factory modularization enhances manufacturing efficiency by breaking down complex assembly lines into smaller, flexible modules that can be rapidly reconfigured for customized production. This approach reduces lead times, optimizes resource allocation, and supports scalable, lean manufacturing processes compared to traditional linear assembly lines.

Adaptive Workstations

Adaptive workstations in assembly lines enhance efficiency by automatically adjusting to product variations and operator preferences, reducing downtime and increasing throughput. In modular production, these workstations provide flexibility by allowing rapid reconfiguration for different modules, supporting customization and faster response to market demands.

Collaborative Modular Robotics

Collaborative modular robotics enhance manufacturing efficiency by integrating flexible, reconfigurable units that adapt quickly to varying assembly line tasks, reducing downtime and increasing productivity. Compared to traditional assembly lines, these robots enable scalable modular production with improved precision, real-time data exchange, and seamless human-robot collaboration.

Assembly Line vs Modular Production Infographic

industrydif.com

industrydif.com