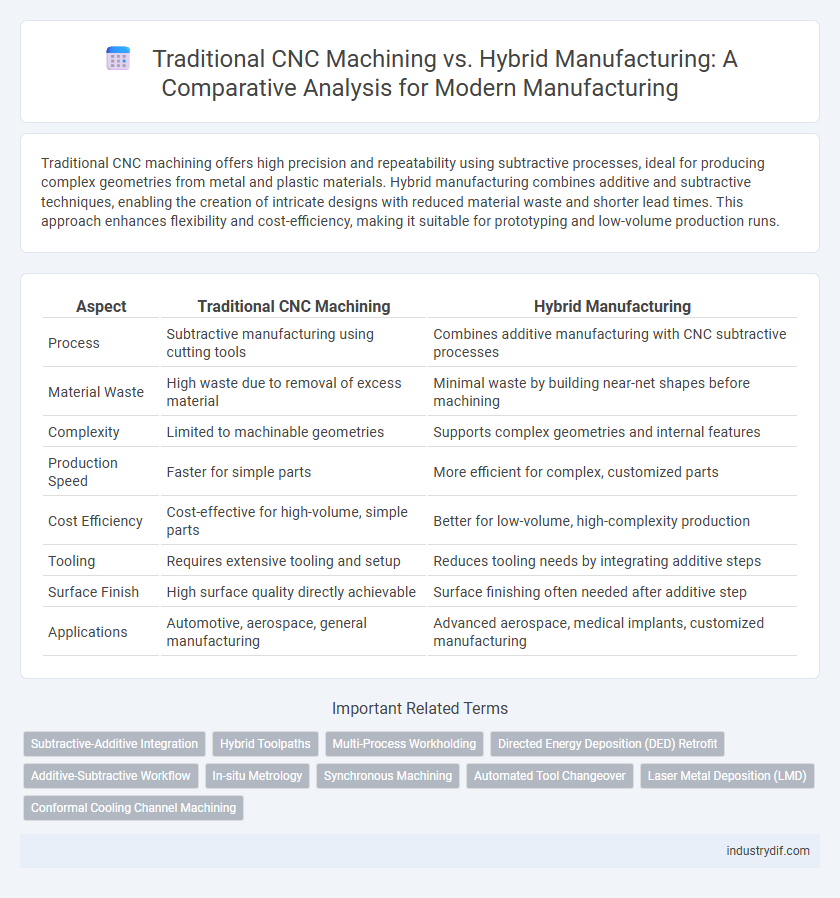

Traditional CNC machining offers high precision and repeatability using subtractive processes, ideal for producing complex geometries from metal and plastic materials. Hybrid manufacturing combines additive and subtractive techniques, enabling the creation of intricate designs with reduced material waste and shorter lead times. This approach enhances flexibility and cost-efficiency, making it suitable for prototyping and low-volume production runs.

Table of Comparison

| Aspect | Traditional CNC Machining | Hybrid Manufacturing |

|---|---|---|

| Process | Subtractive manufacturing using cutting tools | Combines additive manufacturing with CNC subtractive processes |

| Material Waste | High waste due to removal of excess material | Minimal waste by building near-net shapes before machining |

| Complexity | Limited to machinable geometries | Supports complex geometries and internal features |

| Production Speed | Faster for simple parts | More efficient for complex, customized parts |

| Cost Efficiency | Cost-effective for high-volume, simple parts | Better for low-volume, high-complexity production |

| Tooling | Requires extensive tooling and setup | Reduces tooling needs by integrating additive steps |

| Surface Finish | High surface quality directly achievable | Surface finishing often needed after additive step |

| Applications | Automotive, aerospace, general manufacturing | Advanced aerospace, medical implants, customized manufacturing |

Introduction to CNC Machining in Modern Manufacturing

CNC machining remains a cornerstone in modern manufacturing, enabling precise, repeatable production of complex parts from metals and plastics. Traditional CNC machining relies on subtractive processes, removing material to achieve desired geometries with high accuracy. Hybrid manufacturing integrates additive and subtractive techniques, enhancing flexibility and reducing lead times while maintaining the precision associated with conventional CNC machines.

Defining Traditional CNC Machining Processes

Traditional CNC machining processes involve subtractive manufacturing techniques where computer numerical control machines precisely remove material from a solid block to create components. These processes rely on milling, turning, and drilling with high accuracy and repeatability, primarily using metals and polymers. CNC machining excels in producing complex geometries with tight tolerances but is limited by material waste and longer lead times compared to newer hybrid manufacturing methods.

Understanding Hybrid Manufacturing Technologies

Hybrid manufacturing integrates traditional CNC machining with additive manufacturing, enabling complex geometries and reducing material waste. This technology combines precision cutting and layer-by-layer building, enhancing design flexibility and production efficiency. Industries adopting hybrid methods benefit from faster prototyping and the ability to create parts with customized material properties.

Core Differences: Traditional CNC vs Hybrid Manufacturing

Traditional CNC machining relies solely on subtractive processes, where material is removed from a solid block to achieve the desired shape, offering high precision and surface finish. Hybrid manufacturing combines additive manufacturing techniques, such as 3D printing, with CNC machining to enable complex geometries, reduce material waste, and shorten production times. Core differences include the ability of hybrid systems to build internal features and integrate multiple manufacturing steps, while traditional CNC excels in finishing and machining accuracy.

Materials Compatibility: CNC Machining and Hybrid Approaches

CNC machining excels with metals such as aluminum, steel, and titanium, offering precise cuts and smooth finishes on solid materials. Hybrid manufacturing combines additive processes like 3D printing with subtractive CNC machining, enhancing compatibility for complex geometries and multi-material components including polymers and composites. This integration expands material versatility and reduces production time by enabling in-situ machining of additively manufactured parts.

Precision, Accuracy, and Surface Finish Comparisons

Traditional CNC machining excels in precision and accuracy due to its well-established subtractive processes, delivering tight tolerances within microns. Hybrid manufacturing combines additive and subtractive methods, enhancing surface finish quality by reducing material stress and enabling complex geometries with improved dimensional control. Studies show hybrid systems achieve comparable accuracy to CNC machining while offering superior surface finishes and reduced post-processing requirements.

Production Speed and Cost Efficiency Analysis

Traditional CNC machining offers predictable production speed with established cost parameters but can become time-consuming and expensive for complex geometries due to multiple setups and tool changes. Hybrid manufacturing integrates additive and subtractive processes in a single machine, significantly enhancing production speed by reducing lead times and minimizing material waste. Cost efficiency improves with hybrid systems as they lower operational expenses through streamlined workflows, enabling faster prototyping and reduced post-processing requirements.

Applications Suited for Each Manufacturing Method

Traditional CNC machining excels in precision parts production for aerospace, automotive, and medical industries, especially when working with metals and hard materials requiring tight tolerances. Hybrid manufacturing combines additive and subtractive processes, ideal for complex geometries, lightweight aerospace components, and rapid prototyping with materials like titanium and composites. Applications demanding customization, intricate internal structures, or reduced material waste benefit significantly from hybrid manufacturing's integrated capabilities.

Challenges and Limitations of Both Technologies

Traditional CNC machining faces challenges such as limited geometric complexity, high material waste, and lengthy setup times, impacting production efficiency for intricate parts. Hybrid manufacturing combines additive and subtractive processes but encounters limitations like increased machine costs, complex process integration, and potential inconsistencies in material properties between deposited and machined areas. Both technologies must address precision trade-offs and post-processing requirements to optimize part quality and manufacturing flexibility.

Future Trends in CNC and Hybrid Manufacturing Integration

Future trends in CNC and hybrid manufacturing integration highlight the increased adoption of advanced automation technologies and real-time data analytics to optimize production efficiency and precision. The convergence of additive manufacturing with traditional CNC machining enables complex part fabrication with reduced lead times and material waste. Industry 4.0 advancements, including IoT connectivity and AI-driven process control, drive smarter, more flexible manufacturing environments.

Related Important Terms

Subtractive-Additive Integration

Traditional CNC machining relies solely on subtractive processes, removing material from a workpiece to achieve precise dimensions and surface finishes. Hybrid manufacturing integrates additive techniques with subtractive CNC operations, enabling complex geometries, reduced material waste, and enhanced production efficiency by combining layer-by-layer material addition with precise machining.

Hybrid Toolpaths

Hybrid toolpaths integrate additive and subtractive processes within a single CNC machine, enhancing precision and reducing production time by minimizing tool changes and repositioning. This approach optimizes material usage and enables complex geometries that are challenging for traditional CNC machining alone.

Multi-Process Workholding

Traditional CNC machining relies on fixed workholding setups that limit the ability to perform multiple processes without repositioning the part, increasing cycle time and potential errors. Hybrid manufacturing integrates multi-process workholding systems that enable seamless transitions between additive and subtractive operations, enhancing precision and reducing overall production time.

Directed Energy Deposition (DED) Retrofit

Traditional CNC machining relies on subtractive processes that remove material from a solid block, offering precision and repeatability but limited flexibility for complex geometries. Hybrid manufacturing with Directed Energy Deposition (DED) retrofit enhances production by combining additive layering with CNC precision, enabling efficient repair, customization, and reduced material waste in aerospace and automotive industries.

Additive-Subtractive Workflow

Traditional CNC machining relies solely on subtractive processes, removing material from a solid block to achieve precise dimensions, while hybrid manufacturing integrates additive and subtractive workflows, enabling the creation of complex geometries with enhanced material efficiency and reduced lead times. The additive-subtractive workflow allows for the deposition of material in intricate patterns followed by precision milling, effectively minimizing waste and expanding design possibilities in advanced manufacturing applications.

In-situ Metrology

Traditional CNC machining relies on fixed off-line inspection methods that can increase production time and reduce accuracy due to delayed error detection. Hybrid manufacturing integrates in-situ metrology systems directly into the machining process, enabling real-time dimensional verification and immediate corrections that enhance precision and reduce scrap rates.

Synchronous Machining

Synchronous machining in hybrid manufacturing integrates additive and subtractive processes in a single setup, reducing lead times and improving precision compared to traditional CNC machining, which operates in sequential stages. This approach enhances the manufacturing of complex geometries by enabling simultaneous multi-axis cutting and material deposition, increasing overall productivity and flexibility.

Automated Tool Changeover

Traditional CNC machining relies on manual or semi-automated tool changeover processes, often leading to longer downtime and reduced production efficiency. Hybrid manufacturing integrates automated tool changeover systems, significantly minimizing machine idle time and enhancing throughput in complex manufacturing workflows.

Laser Metal Deposition (LMD)

Traditional CNC machining relies on subtractive processes to shape metal components with high precision, while hybrid manufacturing integrates Laser Metal Deposition (LMD) to add material, enabling repair and complex geometry fabrication. LMD enhances manufacturing flexibility by combining additive and subtractive techniques, reducing material waste and production time in aerospace and automotive industries.

Conformal Cooling Channel Machining

Traditional CNC machining of conformal cooling channels involves precise subtractive processes that ensure accurate geometries but often require complex setups and multiple tooling changes, leading to longer production times. Hybrid manufacturing integrates additive techniques with CNC machining to create intricate conformal cooling channels efficiently, enhancing thermal management and reducing cycle times in mold and die components.

Traditional CNC Machining vs Hybrid Manufacturing Infographic

industrydif.com

industrydif.com