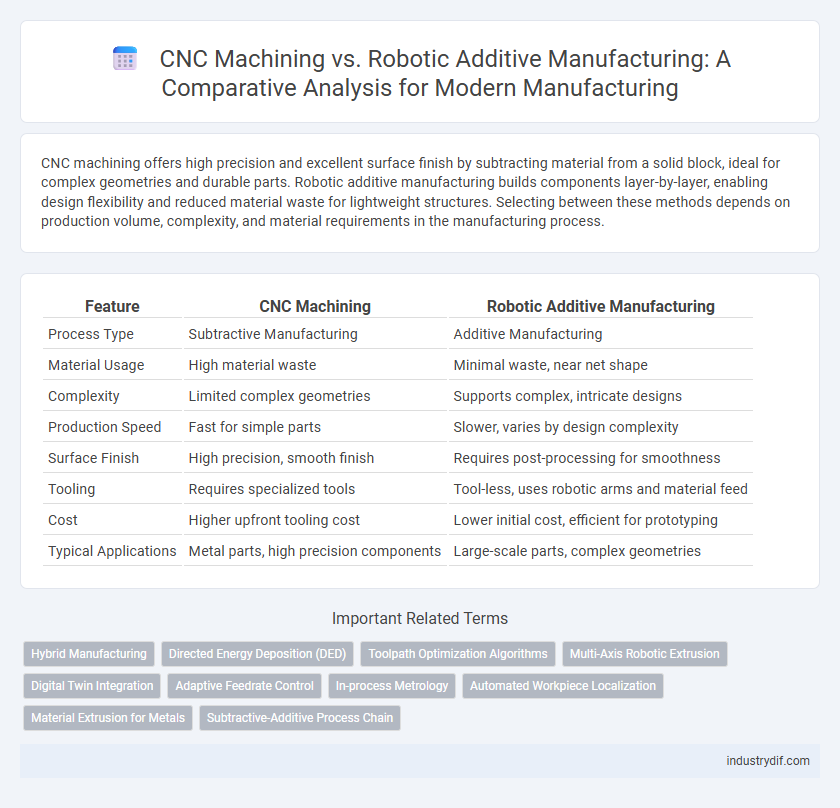

CNC machining offers high precision and excellent surface finish by subtracting material from a solid block, ideal for complex geometries and durable parts. Robotic additive manufacturing builds components layer-by-layer, enabling design flexibility and reduced material waste for lightweight structures. Selecting between these methods depends on production volume, complexity, and material requirements in the manufacturing process.

Table of Comparison

| Feature | CNC Machining | Robotic Additive Manufacturing |

|---|---|---|

| Process Type | Subtractive Manufacturing | Additive Manufacturing |

| Material Usage | High material waste | Minimal waste, near net shape |

| Complexity | Limited complex geometries | Supports complex, intricate designs |

| Production Speed | Fast for simple parts | Slower, varies by design complexity |

| Surface Finish | High precision, smooth finish | Requires post-processing for smoothness |

| Tooling | Requires specialized tools | Tool-less, uses robotic arms and material feed |

| Cost | Higher upfront tooling cost | Lower initial cost, efficient for prototyping |

| Typical Applications | Metal parts, high precision components | Large-scale parts, complex geometries |

Introduction to CNC Machining and Robotic Additive Manufacturing

CNC Machining involves subtractive manufacturing processes where computer-controlled cutting tools precisely remove material from a solid block to create intricate parts with high accuracy and repeatability. Robotic Additive Manufacturing builds components layer-by-layer by depositing materials such as metals or polymers through programmable robotic arms, enabling complex geometries and reduced material waste. Both methods enhance production efficiency but differ in approach, with CNC Machining excelling in precision and surface finish, while Robotic Additive Manufacturing offers design flexibility and rapid prototyping capabilities.

Core Principles: Subtractive vs Additive Processes

CNC machining operates on a subtractive manufacturing principle, where material is precisely removed from a solid block using computer-controlled cutting tools, ensuring high accuracy and surface finish. Robotic additive manufacturing builds components layer by layer by depositing material, enabling complex geometries and reducing waste. The fundamental difference lies in CNC's material removal versus robotic additive's material addition, influencing design flexibility and production efficiency.

Materials Compatibility in CNC and Additive Manufacturing

CNC machining excels in working with a wide range of metals such as aluminum, steel, and titanium, as well as plastics, offering precise material removal for complex geometries. Robotic additive manufacturing, on the other hand, supports materials like polymers, composites, and certain metal powders, enabling layer-by-layer construction ideal for complex shapes and lightweight structures. Material compatibility in CNC machining ensures high surface finish and strength, while additive methods prioritize design flexibility and reduced material waste.

Precision and Tolerances: Comparing Output Quality

CNC machining delivers exceptional precision with tolerances often within +-0.001 mm, making it ideal for components requiring tight dimensional accuracy. Robotic additive manufacturing offers increased flexibility in complex geometries but typically achieves looser tolerances, around +-0.1 mm, which may necessitate post-processing for high-precision applications. Comparing output quality, CNC machining remains the preferred method for industries demanding exacting standards such as aerospace and medical device manufacturing.

Speed and Production Efficiency Analysis

CNC machining offers high precision and faster cycle times for producing complex metal parts, making it ideal for low to medium-volume manufacturing with consistent repeatability. Robotic additive manufacturing excels in rapid prototyping and reducing material waste by building parts layer-by-layer, which significantly decreases lead times for complex geometries and customized components. Combining CNC machining with robotic additive processes can optimize production efficiency by leveraging CNC's speed for finishing and additive's flexibility for initial build stages.

Cost Factors and Economic Considerations

CNC machining involves higher initial tooling and setup costs but often results in lower per-unit expenses for large production runs due to material efficiency and precision. Robotic additive manufacturing reduces waste and enables complex geometries, lowering costs for prototypes and low-volume parts despite higher material costs and slower build times. Evaluating total cost of ownership must include machine depreciation, labor, and post-processing expenses to determine the most economical manufacturing approach.

Flexibility and Customization Capabilities

CNC machining offers high precision and repeatability but is limited in flexibility when producing complex geometries or bespoke parts, relying heavily on pre-programmed tool paths. Robotic additive manufacturing excels in customization, enabling the creation of intricate designs and varying product configurations without extensive tooling changes. This adaptability makes robotic additive methods ideal for low-volume, highly customized production runs, complementing CNC machining's strengths in standardized manufacturing.

Industrial Applications and Use Cases

CNC machining excels in producing precise metal and plastic components with tight tolerances, making it ideal for aerospace, automotive, and medical device manufacturing. Robotic additive manufacturing enhances flexibility by enabling complex, lightweight parts and rapid prototyping, widely used in customized tooling, aerospace structural components, and small batch production. Both technologies complement each other by addressing different industrial needs: CNC machining for accuracy and surface finish, and robotic additive manufacturing for design innovation and material efficiency.

Sustainability and Waste Management

CNC machining generates significant material waste due to its subtractive process, whereas robotic additive manufacturing builds components layer by layer, minimizing excess material and reducing scrap. Additive methods enhance sustainability by lowering raw material consumption and energy use, supporting circular manufacturing principles. Waste management improves with additive technologies through easier recycling of unused powders and parts, decreasing landfill contributions compared to traditional CNC machined scraps.

Future Trends in Automated Manufacturing Technologies

Future trends in automated manufacturing emphasize the integration of CNC machining and robotic additive manufacturing to enhance precision and efficiency. Advanced AI-driven controls and real-time monitoring systems are accelerating the adoption of hybrid manufacturing processes that combine subtractive and additive techniques. These innovations are driving higher customization capabilities, reduced production times, and lower material waste across industries.

Related Important Terms

Hybrid Manufacturing

Hybrid manufacturing combines CNC machining's precision subtractive processes with robotic additive manufacturing's layer-by-layer material deposition to enhance production efficiency and design complexity. This integration leverages CNC's tight tolerances and robotics' flexibility for rapid prototyping and high-strength part fabrication in aerospace and automotive sectors.

Directed Energy Deposition (DED)

Directed Energy Deposition (DED) in robotic additive manufacturing enables precise metal deposition and complex geometries unattainable by traditional CNC machining, significantly reducing material waste and production time. CNC machining excels in high-precision subtractive processes, offering superior surface finishes and tight tolerances, but it often involves longer lead times and increased material removal compared to DED's layer-by-layer fabrication.

Toolpath Optimization Algorithms

Toolpath optimization algorithms in CNC machining enhance precision by minimizing tool travel distance and reducing machining time, resulting in improved surface finish and lower production costs. In robotic additive manufacturing, these algorithms optimize deposition paths to ensure consistent material distribution and structural integrity, increasing efficiency and reducing waste in complex geometric builds.

Multi-Axis Robotic Extrusion

Multi-axis robotic extrusion in additive manufacturing offers complex geometries and material efficiency unattainable by traditional CNC machining, which excels in high-precision subtraction processes. By integrating robotics with advanced extrusion techniques, manufacturers achieve faster prototyping and reduced material waste, enhancing production scalability and customization.

Digital Twin Integration

Digital twin integration enhances CNC machining by providing real-time simulation and predictive maintenance, reducing downtime and optimizing precision in subtractive manufacturing processes. In robotic additive manufacturing, digital twins enable adaptive control and intricate design validation, improving build quality and accelerating production of complex geometries.

Adaptive Feedrate Control

Adaptive feedrate control in CNC machining enhances precision by dynamically adjusting tool speed based on material hardness and cutting conditions, reducing tool wear and improving surface finish. In contrast, robotic additive manufacturing benefits from adaptive feedrate control by optimizing deposition rates to ensure consistent layer bonding and minimize defects in complex geometries.

In-process Metrology

In-process metrology in CNC machining enables real-time measurement and adjustment, ensuring high precision and minimal material waste by continuously monitoring tool wear and part dimensions. Robotic additive manufacturing integrates in-process metrology through sensors and machine vision systems, allowing layer-by-layer quality control and defect detection to optimize build accuracy and reduce post-processing efforts.

Automated Workpiece Localization

Automated workpiece localization in CNC machining relies on precise coordinate mapping and fixed fixtures to ensure high accuracy and repeatability during subtractive processes. Robotic additive manufacturing utilizes advanced sensor fusion and machine vision for dynamic positioning, enabling flexible material deposition on complex geometries without rigid setups.

Material Extrusion for Metals

Material extrusion in robotic additive manufacturing enables precise layer-by-layer deposition of metal powders, facilitating complex geometries and reduced material waste compared to traditional CNC machining, which relies on subtractive processes to remove metal from solid blocks. CNC machining offers superior surface finish and dimensional accuracy, while robotic additive manufacturing excels in producing lightweight, customized metal parts with minimal tooling costs and faster prototyping cycles.

Subtractive-Additive Process Chain

The subtractive-additive process chain combines CNC machining and robotic additive manufacturing to optimize precision and material efficiency, enabling complex geometries and enhanced surface finishes. Integrating CNC's high accuracy with additive layering reduces waste and shortens production cycles, driving innovation in advanced manufacturing workflows.

CNC Machining vs Robotic Additive Manufacturing Infographic

industrydif.com

industrydif.com