Automation streamlines manufacturing by using machines to perform repetitive tasks with high precision and speed, significantly reducing human error and operational costs. Collaborative robotics, or cobots, enhance this process by working alongside human operators, increasing flexibility and safety on the production line. Integrating automation with collaborative robotics optimizes efficiency, improves workforce productivity, and accelerates innovation in modern manufacturing environments.

Table of Comparison

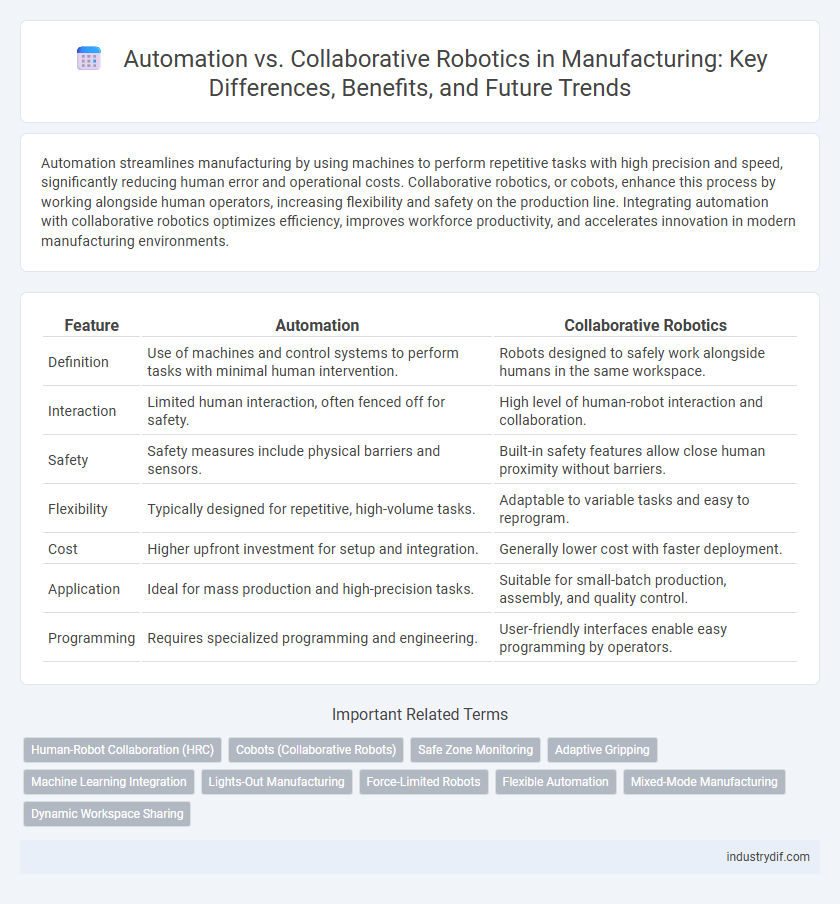

| Feature | Automation | Collaborative Robotics |

|---|---|---|

| Definition | Use of machines and control systems to perform tasks with minimal human intervention. | Robots designed to safely work alongside humans in the same workspace. |

| Interaction | Limited human interaction, often fenced off for safety. | High level of human-robot interaction and collaboration. |

| Safety | Safety measures include physical barriers and sensors. | Built-in safety features allow close human proximity without barriers. |

| Flexibility | Typically designed for repetitive, high-volume tasks. | Adaptable to variable tasks and easy to reprogram. |

| Cost | Higher upfront investment for setup and integration. | Generally lower cost with faster deployment. |

| Application | Ideal for mass production and high-precision tasks. | Suitable for small-batch production, assembly, and quality control. |

| Programming | Requires specialized programming and engineering. | User-friendly interfaces enable easy programming by operators. |

Introduction to Automation and Collaborative Robotics

Automation in manufacturing streamlines repetitive tasks through programmable machines, enhancing efficiency and precision. Collaborative robotics, or cobots, are designed to work safely alongside human operators, improving flexibility and productivity on the factory floor. Integration of both technologies drives innovation by combining machine speed with human adaptability in modern industrial processes.

Key Differences Between Automation and Collaborative Robotics

Automation in manufacturing primarily involves programmed machinery performing repetitive tasks with minimal human intervention, enhancing speed and precision. Collaborative robotics integrates robots that work alongside human operators, emphasizing safety features and adaptability to dynamic environments. Key differences include the level of human interaction, with automation often isolated from workers, whereas collaborative robots (cobots) share the workspace and can adjust to human inputs in real time.

Historical Evolution in Manufacturing Technologies

Manufacturing technologies have evolved from traditional automation systems, such as programmable logic controllers (PLCs) and fixed robotic arms, to advanced collaborative robots (cobots) designed for seamless human-machine interaction. Early automation emphasized high-speed, repetitive tasks with minimal human intervention, while collaborative robotics emerged in the 2000s to enhance flexibility, safety, and productivity within mixed work environments. The historical shift reflects a trend towards integrating intelligent sensors, machine learning, and real-time data analytics to optimize manufacturing efficiency and adaptability.

Core Benefits of Automation in Manufacturing

Automation in manufacturing significantly enhances production efficiency by enabling continuous operation and reducing human error. It delivers consistent product quality through precise, repeatable processes and lowers operational costs by minimizing labor-intensive tasks. Advanced automation systems integrate seamlessly with smart factories, driving scalability and real-time data analytics for optimized decision-making.

Advantages of Collaborative Robotics in Industrial Settings

Collaborative robotics enhance industrial productivity by enabling safe human-robot interaction without extensive safety barriers, reducing downtime and floor space. These robots offer flexibility for varied tasks through easy programming and quick redeployment, adapting to changing manufacturing processes. Enhanced precision and consistent performance improve product quality while alleviating repetitive and ergonomically challenging tasks for workers.

Safety Considerations: Automation vs Collaborative Robots

Automation systems in manufacturing often operate in isolated environments with safety barriers to prevent human contact, ensuring operator protection through physical separation and programmed emergency stops. Collaborative robots (cobots) integrate sensors and force-limiting technologies to detect human presence and reduce operational speed or halt actions, allowing safe interaction without extensive guarding. Risk assessment standards like ISO 10218 and ISO/TS 15066 guide the implementation of safety measures tailored to the specific dynamics of automation and collaborative robotics in production settings.

Workforce Impact and Job Transformation

Automation in manufacturing significantly enhances productivity by performing repetitive tasks, leading to job displacement in roles focused on manual labor while creating demand for skilled workers in programming and maintenance. Collaborative robotics, integrated alongside human workers, promotes job transformation by augmenting human capabilities, reducing physical strain, and enabling employees to focus on higher-level decision-making and quality control. Workforce impact includes the evolving need for continuous upskilling and reskilling, fostering a shift toward roles centered on robot supervision, data analysis, and system optimization.

Integration Challenges and Solutions

Automation in manufacturing often faces integration challenges such as compatibility with legacy systems and complex programming requirements, which can delay deployment and increase costs. Collaborative robotics (cobots) offer more flexible integration through user-friendly interfaces and adaptive sensors that ensure safer human-robot interaction on the factory floor. Solutions include modular software platforms, standardized communication protocols like OPC UA, and comprehensive workforce training to enhance seamless COBOT integration and maximize productivity gains.

Cost-Benefit Analysis: Automation vs Collaborative Robotics

Automation in manufacturing delivers high initial investment but yields significant long-term cost savings through increased throughput and reduced labor expenses. Collaborative robotics (cobots) require lower upfront costs and offer flexibility with quicker deployment, making them cost-effective for small to medium production runs. Evaluating the return on investment involves comparing production volume, task complexity, and workforce integration to determine the optimal balance between automation and cobot implementation.

Future Trends in Manufacturing Robotics

Future trends in manufacturing robotics highlight a growing integration of automation and collaborative robotics to enhance production efficiency and flexibility. Advances in AI-powered sensors and machine learning algorithms enable collaborative robots (cobots) to safely work alongside human operators, optimizing complex assembly lines and reducing downtime. The shift towards smart factories leverages interconnected robotic systems for real-time data analysis, predictive maintenance, and adaptive manufacturing processes, driving Industry 4.0 innovations.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) in manufacturing integrates automation with collaborative robotics to enhance productivity and safety by enabling robots and humans to work side-by-side without physical barriers. Collaborative robots are designed with advanced sensors and AI to dynamically adapt to human movements, fostering efficient workflow and reducing ergonomic risks in assembly lines.

Cobots (Collaborative Robots)

Cobots, or collaborative robots, enhance manufacturing efficiency by working safely alongside human operators without the need for extensive safety barriers, enabling flexible automation in tasks like assembly and quality control. Unlike traditional automation, which often requires isolated environments and complex programming, cobots adapt easily to changing production demands, reducing downtime and boosting overall productivity.

Safe Zone Monitoring

Safe zone monitoring in manufacturing enhances automation efficiency by using sensors and AI to detect and prevent human-robot collisions, ensuring operational safety. Collaborative robotics integrate real-time safe zone monitoring to allow humans and robots to work side-by-side, boosting productivity while maintaining strict safety protocols.

Adaptive Gripping

Adaptive gripping technology in automation enables machines to handle a diverse range of products with precision, improving efficiency and reducing downtime in manufacturing processes. Collaborative robotics integrate adaptive gripping systems with human-robot interaction, enhancing flexibility and safety on production lines.

Machine Learning Integration

Automation in manufacturing leverages machine learning integration to optimize repetitive processes and enhance precision through predictive maintenance and quality control. Collaborative robotics, embedded with advanced machine learning algorithms, enable dynamic interaction with human operators, adapting in real-time to complex assembly tasks and improving workflow flexibility.

Lights-Out Manufacturing

Automation in manufacturing emphasizes fully autonomous systems designed for lights-out manufacturing, minimizing human intervention to increase efficiency and reduce operational costs. Collaborative robotics integrates robots that work alongside human operators, enhancing flexibility but typically requiring human presence, which contrasts with the uninterrupted, 24/7 production capability of lights-out facilities.

Force-Limited Robots

Force-limited robots in manufacturing enhance safety by automatically adjusting applied force to prevent injuries, enabling seamless human-robot collaboration without physical barriers. Automation-focused systems prioritize speed and precision through pre-programmed tasks, while force-limited collaborative robots adapt dynamically to unpredictable environments, improving flexibility and worker interaction.

Flexible Automation

Flexible automation in manufacturing integrates programmable machines that adapt seamlessly to changing production demands, offering higher efficiency and scalability compared to traditional automation systems. Collaborative robotics enhance this flexibility by enabling human-robot interaction on the factory floor, improving precision and reducing downtime through shared tasks without extensive reprogramming.

Mixed-Mode Manufacturing

Automation in mixed-mode manufacturing enhances efficiency by integrating high-speed robotic systems for repetitive tasks, while collaborative robotics enable flexible human-robot interaction to adapt to varying production requirements. Combining traditional automation with collaborative robots optimizes workflow, improves safety, and allows seamless transitions between batch and custom manufacturing processes.

Dynamic Workspace Sharing

Automation in manufacturing excels at high-speed, repetitive tasks within fixed environments, while collaborative robotics prioritize dynamic workspace sharing by safely interacting with human workers in flexible settings. Integrating collaborative robots enables real-time adjustments and enhances productivity through seamless human-robot cooperation on complex assembly lines.

Automation vs Collaborative Robotics Infographic

industrydif.com

industrydif.com