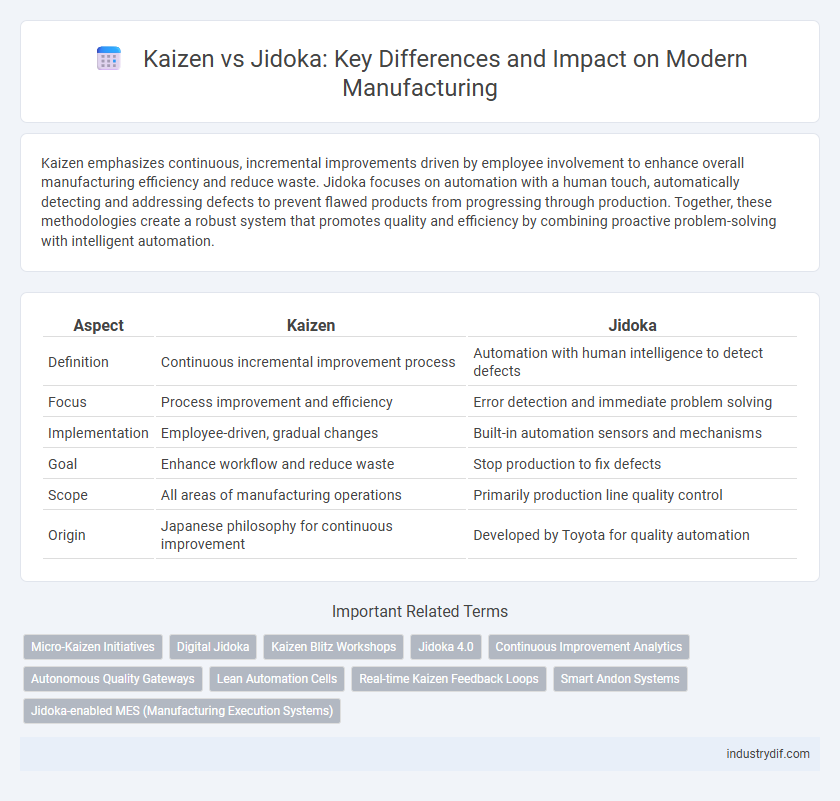

Kaizen emphasizes continuous, incremental improvements driven by employee involvement to enhance overall manufacturing efficiency and reduce waste. Jidoka focuses on automation with a human touch, automatically detecting and addressing defects to prevent flawed products from progressing through production. Together, these methodologies create a robust system that promotes quality and efficiency by combining proactive problem-solving with intelligent automation.

Table of Comparison

| Aspect | Kaizen | Jidoka |

|---|---|---|

| Definition | Continuous incremental improvement process | Automation with human intelligence to detect defects |

| Focus | Process improvement and efficiency | Error detection and immediate problem solving |

| Implementation | Employee-driven, gradual changes | Built-in automation sensors and mechanisms |

| Goal | Enhance workflow and reduce waste | Stop production to fix defects |

| Scope | All areas of manufacturing operations | Primarily production line quality control |

| Origin | Japanese philosophy for continuous improvement | Developed by Toyota for quality automation |

Understanding Kaizen: The Principle of Continuous Improvement

Kaizen emphasizes continuous improvement through small, incremental changes that engage all employees in the manufacturing process to enhance efficiency and reduce waste. This principle fosters a culture where ongoing feedback and collaborative problem-solving drive measurable productivity gains. Unlike Jidoka, which focuses on automation and stopping production to fix defects, Kaizen centers on proactive human involvement to optimize processes systematically.

Jidoka Explained: Automation with a Human Touch

Jidoka, a core principle in lean manufacturing, integrates automation with human oversight to enhance quality control and prevent defects. This approach empowers machines to detect abnormalities and halt production immediately, allowing workers to address issues promptly and maintain operational efficiency. Unlike Kaizen's continuous improvement focus, Jidoka emphasizes building intelligence into the manufacturing process to ensure real-time problem-solving and defect prevention.

Origins and Philosophical Foundations of Kaizen and Jidoka

Kaizen originated in post-World War II Japan, emphasizing continuous incremental improvements driven by every employee, rooted in the philosophy of collective responsibility and employee empowerment. Jidoka, developed by Sakichi Toyoda in the early 20th century, embodies the principle of "automation with a human touch," integrating intelligent automation to detect defects and stop production to prevent errors. Both concepts arise from the Toyota Production System, reflecting a shared focus on quality, efficiency, and respect for people but differ in their approach to process control and improvement.

Core Differences: Kaizen vs. Jidoka in Manufacturing

Kaizen in manufacturing emphasizes continuous incremental improvements by engaging all employees to optimize processes and reduce waste over time. Jidoka, on the other hand, focuses on automating quality control by enabling machines to detect defects and halt production automatically to prevent errors. While Kaizen fosters a culture of ongoing employee-driven innovation, Jidoka ensures immediate defect detection and containment through autonomous automation.

Practical Applications of Kaizen in the Factory Floor

Kaizen emphasizes continuous, incremental improvements by engaging all employees on the factory floor to identify and eliminate inefficiencies, streamline workflows, and enhance product quality. Practical applications include regular team meetings for problem-solving, standardized work procedures, and immediate corrective actions to prevent defects. Unlike Jidoka, which automates defect detection and stops machines, Kaizen fosters a culture of proactive human-led innovation and process optimization.

Implementing Jidoka: Key Considerations for Manufacturers

Implementing Jidoka requires manufacturers to integrate automated quality control systems that detect defects in real-time, minimizing waste and enhancing product consistency. Emphasizing human-machine collaboration, Jidoka empowers operators to halt production immediately when abnormalities occur, fostering a culture of proactive problem-solving. Ensuring thorough training and clear communication channels is crucial to maximize the effectiveness of Jidoka within lean manufacturing environments.

Benefits of Kaizen: Driving Long-Term Process Efficiency

Kaizen emphasizes continuous, incremental improvements that empower employees to identify and eliminate inefficiencies, resulting in sustained process enhancements. Its focus on team engagement and small, manageable changes drives consistent productivity gains and cost reductions over time. This approach leads to a culture of ongoing innovation, fostering long-term operational excellence and agility in manufacturing environments.

The Impact of Jidoka on Quality Control

Jidoka significantly enhances quality control by enabling immediate detection and automatic correction of defects during production, reducing the risk of faulty products reaching customers. This approach empowers workers to halt the manufacturing process when abnormalities occur, fostering a culture of continuous improvement and defect prevention. Implementing Jidoka leads to higher product reliability, decreased waste, and streamlined operations compared to traditional Kaizen practices focused primarily on incremental improvements.

Integrating Kaizen and Jidoka: Synergy for Lean Manufacturing

Integrating Kaizen and Jidoka creates a powerful synergy that enhances lean manufacturing by combining continuous improvement with automation and quality control. Kaizen fosters ongoing employee-driven enhancements, while Jidoka introduces intelligent automation that immediately detects and addresses defects, preventing defective products from progressing. This integration minimizes waste, improves efficiency, and boosts overall production quality by ensuring that improvements are both human-centered and technologically supported.

Overcoming Challenges in Adopting Kaizen and Jidoka

Overcoming challenges in adopting Kaizen and Jidoka requires addressing cultural resistance and ensuring continuous employee engagement in manufacturing processes. Implementing structured training programs and fostering transparent communication helps integrate Kaizen's incremental improvements with Jidoka's automation and quality control principles. Data-driven performance metrics enable manufacturers to monitor progress and adjust strategies for seamless adoption of these lean methodologies.

Related Important Terms

Micro-Kaizen Initiatives

Micro-Kaizen initiatives emphasize continuous small-scale improvements to enhance process efficiency and worker engagement, while Jidoka focuses on automation with human intervention to immediately detect and correct defects. Integrating Micro-Kaizen practices within Jidoka systems drives incremental innovation, reduces downtime, and supports a culture of quality in manufacturing.

Digital Jidoka

Digital Jidoka enhances traditional Jidoka by integrating IoT sensors and real-time data analytics to automatically detect defects and halt production for immediate corrective action, minimizing downtime and improving quality control. Unlike Kaizen's continuous incremental improvements driven by employee input, Digital Jidoka leverages automation and AI to ensure autonomous quality management and faster response in manufacturing processes.

Kaizen Blitz Workshops

Kaizen Blitz Workshops accelerate continuous improvement by enabling rapid, targeted problem-solving in operational processes, contrasting with Jidoka's focus on built-in quality and automation to detect and halt defects. These intensive workshops engage cross-functional teams to identify inefficiencies and implement immediate solutions, significantly enhancing productivity and reducing waste in manufacturing environments.

Jidoka 4.0

Jidoka 4.0 integrates advanced automation with intelligent defect detection systems, enabling immediate machine stoppage upon quality deviations to prevent defective products. This innovation enhances traditional Jidoka principles by incorporating IoT sensors, AI analytics, and real-time data monitoring, which boosts manufacturing efficiency and ensures superior product quality.

Continuous Improvement Analytics

Kaizen emphasizes continuous improvement through small, incremental changes driven by employee involvement, enhancing productivity and quality over time. Jidoka integrates automation with human oversight, enabling real-time defect detection and immediate corrective action to prevent production errors.

Autonomous Quality Gateways

Kaizen emphasizes continuous incremental improvements in manufacturing processes, fostering employee-driven innovation to enhance quality and efficiency. Jidoka, or autonomous quality gateways, empower machines to detect defects and halt production automatically, preventing the spread of errors and ensuring immediate quality control.

Lean Automation Cells

Kaizen in Lean Automation Cells emphasizes continuous incremental improvements by engaging all employees to identify inefficiencies, while Jidoka integrates automation with human oversight to detect and immediately address defects, ensuring quality control. Combining Kaizen's focus on process enhancement with Jidoka's built-in error detection optimizes productivity and reduces waste in manufacturing workflows.

Real-time Kaizen Feedback Loops

Real-time Kaizen feedback loops drive continuous improvement by rapidly identifying and addressing inefficiencies, fostering an adaptive manufacturing environment. In contrast, Jidoka emphasizes autonomous quality control through automated detection and stopping of defects, ensuring immediate correction at the source.

Smart Andon Systems

Smart Andon systems enhance Kaizen by enabling continuous improvement through real-time visual alerts for production abnormalities, while supporting Jidoka by automatically stopping machinery to prevent defects. Integrating these systems promotes proactive quality control and operational efficiency in manufacturing processes.

Jidoka-enabled MES (Manufacturing Execution Systems)

Jidoka-enabled Manufacturing Execution Systems (MES) integrate real-time defect detection and automated stoppage mechanisms to enhance production quality and minimize downtime. This system empowers operators to identify abnormalities immediately, ensuring rapid response and continuous process improvement within smart factories.

Kaizen vs Jidoka Infographic

industrydif.com

industrydif.com