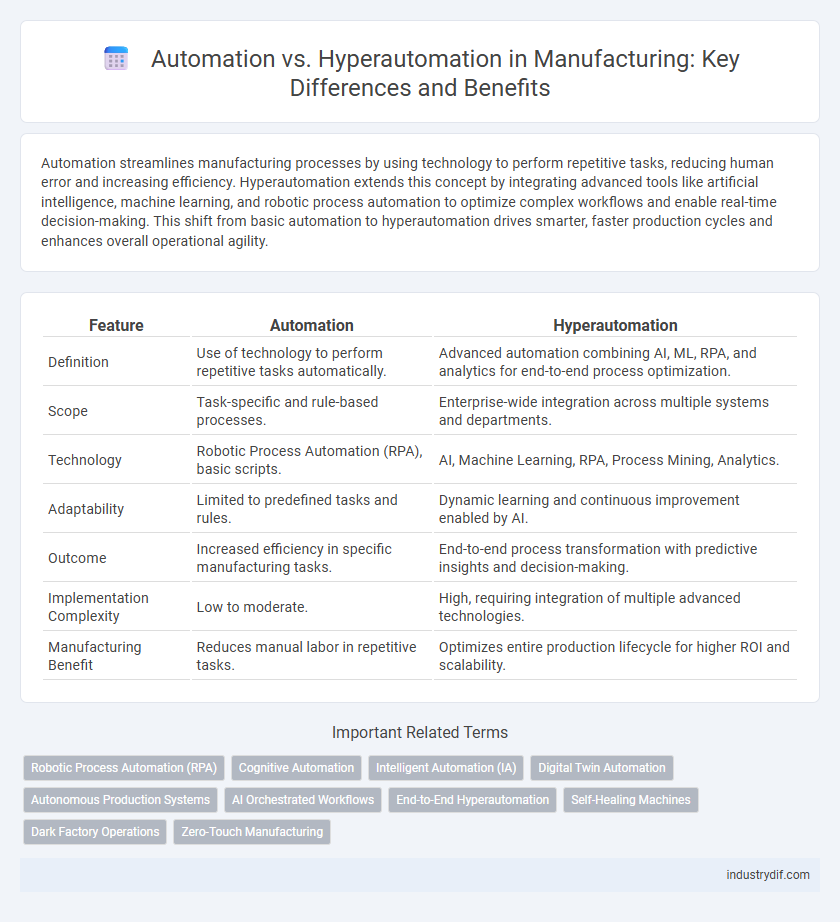

Automation streamlines manufacturing processes by using technology to perform repetitive tasks, reducing human error and increasing efficiency. Hyperautomation extends this concept by integrating advanced tools like artificial intelligence, machine learning, and robotic process automation to optimize complex workflows and enable real-time decision-making. This shift from basic automation to hyperautomation drives smarter, faster production cycles and enhances overall operational agility.

Table of Comparison

| Feature | Automation | Hyperautomation |

|---|---|---|

| Definition | Use of technology to perform repetitive tasks automatically. | Advanced automation combining AI, ML, RPA, and analytics for end-to-end process optimization. |

| Scope | Task-specific and rule-based processes. | Enterprise-wide integration across multiple systems and departments. |

| Technology | Robotic Process Automation (RPA), basic scripts. | AI, Machine Learning, RPA, Process Mining, Analytics. |

| Adaptability | Limited to predefined tasks and rules. | Dynamic learning and continuous improvement enabled by AI. |

| Outcome | Increased efficiency in specific manufacturing tasks. | End-to-end process transformation with predictive insights and decision-making. |

| Implementation Complexity | Low to moderate. | High, requiring integration of multiple advanced technologies. |

| Manufacturing Benefit | Reduces manual labor in repetitive tasks. | Optimizes entire production lifecycle for higher ROI and scalability. |

Defining Automation in Manufacturing

Automation in manufacturing involves using technology and control systems, such as robotics and computer software, to perform repetitive tasks with minimal human intervention. It increases production efficiency, reduces errors, and lowers operational costs by streamlining processes like assembly, quality control, and material handling. Core technologies include programmable logic controllers (PLCs), sensors, and industrial robots, which enable consistent and scalable manufacturing workflows.

Understanding Hyperautomation: Beyond Traditional Automation

Hyperautomation in manufacturing extends beyond traditional automation by integrating advanced technologies such as artificial intelligence, machine learning, robotic process automation (RPA), and data analytics. It enables end-to-end process automation, real-time decision-making, and continuous improvement through intelligent workflows and adaptive systems. This approach transforms production efficiency, reduces manual intervention, and enhances scalability across complex manufacturing environments.

Key Differences Between Automation and Hyperautomation

Automation in manufacturing involves the use of technology to perform repetitive tasks with minimal human intervention, whereas hyperautomation extends this by integrating advanced technologies like artificial intelligence, machine learning, and robotic process automation to automate complex processes end-to-end. Key differences include the scope and scale, as automation targets specific tasks, while hyperautomation aims for comprehensive process optimization and continuous improvement across operations. Data-driven decision-making and real-time analytics are central to hyperautomation, enabling adaptive and intelligent manufacturing workflows beyond traditional automation capabilities.

Core Technologies Driving Manufacturing Automation

Automation in manufacturing primarily relies on robotics, PLCs (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems to streamline repetitive tasks and improve production efficiency. Hyperautomation extends these capabilities by integrating AI-driven process mining, machine learning, and intelligent RPA (Robotic Process Automation) to enable dynamic adaptation and optimization across complex workflows. Core technologies such as IoT sensors, digital twins, and advanced analytics further enhance decision-making precision and predictive maintenance in hyperautomated manufacturing environments.

Integrating AI and Machine Learning in Hyperautomation

Hyperautomation in manufacturing leverages AI and machine learning to enhance process automation beyond traditional automation's rule-based tasks, enabling intelligent decision-making and predictive maintenance. By integrating advanced algorithms, hyperautomation facilitates real-time data analysis and adaptive workflows, significantly improving efficiency and reducing downtime. This strategic use of AI-driven hyperautomation drives innovation and operational excellence in modern manufacturing environments.

Benefits of Automation for Manufacturing Efficiency

Automation in manufacturing significantly enhances efficiency by streamlining repetitive tasks, reducing human error, and accelerating production cycles. Implementing automated systems improves precision and consistency, leading to higher product quality and reduced waste. Cost savings are realized through lower labor expenses and minimized downtime, allowing manufacturers to scale operations effectively while maintaining competitive advantage.

Hyperautomation: Unlocking End-to-End Process Optimization

Hyperautomation leverages advanced technologies such as artificial intelligence, machine learning, and robotic process automation to achieve comprehensive end-to-end process optimization in manufacturing. It enables the seamless integration of disparate systems, automating complex workflows beyond traditional automation's capabilities. This holistic approach drives operational efficiency, reduces costs, and accelerates production cycles through intelligent, adaptive automation.

Implementation Challenges: Automation vs Hyperautomation

Implementation challenges in automation often include rigid integration with legacy systems and limited scalability, restricting process improvements to predefined tasks. Hyperautomation introduces complexities around orchestrating multiple advanced technologies like AI, RPA, and process mining, requiring substantial expertise and robust change management frameworks. Data governance and continuous monitoring become critical as hyperautomation expands automated workflows across diverse manufacturing operations.

Impact on Workforce and Skill Requirements

Automation in manufacturing streamlines repetitive tasks, reducing the need for manual labor and shifting the workforce towards roles requiring technical maintenance and oversight. Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation, demanding higher-level skills in data analysis, programming, and system integration from employees. This transition drives a workforce evolution, emphasizing continuous reskilling and adaptation to complex, technology-driven environments.

Future Trends: The Evolution from Automation to Hyperautomation

Manufacturing is rapidly evolving as hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to create intelligent workflows far beyond traditional automation capabilities. Future trends indicate a shift towards hyperautomation enabling end-to-end process optimization, real-time data analytics, and predictive maintenance, driving higher efficiency and agility in production lines. The evolution underscores increased interoperability of systems and enhanced decision-making powered by digital twins and cognitive automation tools.

Related Important Terms

Robotic Process Automation (RPA)

Robotic Process Automation (RPA) streamlines repetitive manufacturing tasks by using software robots to execute predefined rules and workflows, enhancing operational efficiency and reducing errors. Hyperautomation extends RPA by integrating advanced technologies like AI, machine learning, and process mining to automate complex, end-to-end manufacturing processes with greater scalability and adaptability.

Cognitive Automation

Cognitive automation, a key component of hyperautomation, leverages artificial intelligence and machine learning to enhance manufacturing processes by enabling systems to understand, learn, and make decisions beyond rule-based automation. Unlike traditional automation, cognitive automation integrates data analytics and natural language processing to improve predictive maintenance, quality control, and supply chain optimization in manufacturing.

Intelligent Automation (IA)

Intelligent Automation (IA) in manufacturing enhances production efficiency by integrating AI-driven processes with traditional automation systems, enabling real-time decision-making and predictive maintenance. Hyperautomation extends this by orchestrating multiple IA tools across complex workflows, but IA remains critical for achieving adaptive, data-driven operational improvements.

Digital Twin Automation

Digital Twin Automation enhances traditional Automation by integrating real-time digital replicas of manufacturing processes, enabling predictive analytics and adaptive control systems that optimize production efficiency. Hyperautomation extends this concept by combining Artificial Intelligence, Machine Learning, and robotic process automation to autonomously manage complex workflows, reducing downtime and operational costs.

Autonomous Production Systems

Autonomous Production Systems leverage hyperautomation by integrating AI, machine learning, and advanced robotics to create self-optimizing manufacturing processes that surpass traditional automation's rule-based workflows. These systems enable real-time decision-making and end-to-end process orchestration, significantly increasing operational efficiency, reducing downtime, and enhancing product quality.

AI Orchestrated Workflows

Automation in manufacturing streamlines repetitive tasks using predefined rules, while hyperautomation leverages AI-orchestrated workflows to integrate multiple technologies, enabling dynamic decision-making and continuous process optimization. AI orchestrated workflows enhance manufacturing efficiency by coordinating robotics, IoT sensors, and data analytics, driving real-time adaptability and predictive maintenance.

End-to-End Hyperautomation

End-to-end hyperautomation in manufacturing integrates advanced technologies like AI, machine learning, and robotic process automation to streamline and optimize the entire production lifecycle, surpassing traditional automation methods by enabling dynamic process adaptation and enhanced decision-making. This comprehensive approach reduces operational costs, increases efficiency, and drives innovation through seamless connectivity between systems, data, and workflows.

Self-Healing Machines

Self-healing machines in manufacturing leverage hyperautomation techniques combining AI, machine learning, and IoT for real-time fault detection and autonomous recovery, significantly reducing downtime and maintenance costs. Unlike basic automation, hyperautomation integrates advanced data analytics and adaptive algorithms to enable predictive maintenance and continuous operational resilience.

Dark Factory Operations

Dark Factory Operations leverage hyperautomation to integrate AI-driven robotics, IoT sensors, and advanced data analytics, surpassing traditional automation by enabling fully autonomous production with minimal human intervention. This approach enhances operational efficiency, reduces errors, and allows real-time monitoring and self-optimization in manufacturing environments.

Zero-Touch Manufacturing

Zero-Touch Manufacturing leverages hyperautomation by integrating AI, machine learning, and advanced robotics to create fully autonomous production lines that minimize human intervention and optimize operational efficiency. Unlike traditional automation, hyperautomation enables dynamic process adjustments and real-time decision-making, driving higher precision and scalable manufacturing workflows.

Automation vs Hyperautomation Infographic

industrydif.com

industrydif.com