Just-In-Time (JIT) manufacturing minimizes inventory costs by synchronizing production schedules with demand, enhancing efficiency and reducing waste. Dark factories operate with minimal human intervention, using automation and robotics to maintain continuous production, often in environments without lighting. Combining JIT principles with dark factory automation can streamline supply chains while maximizing productivity and reducing labor costs.

Table of Comparison

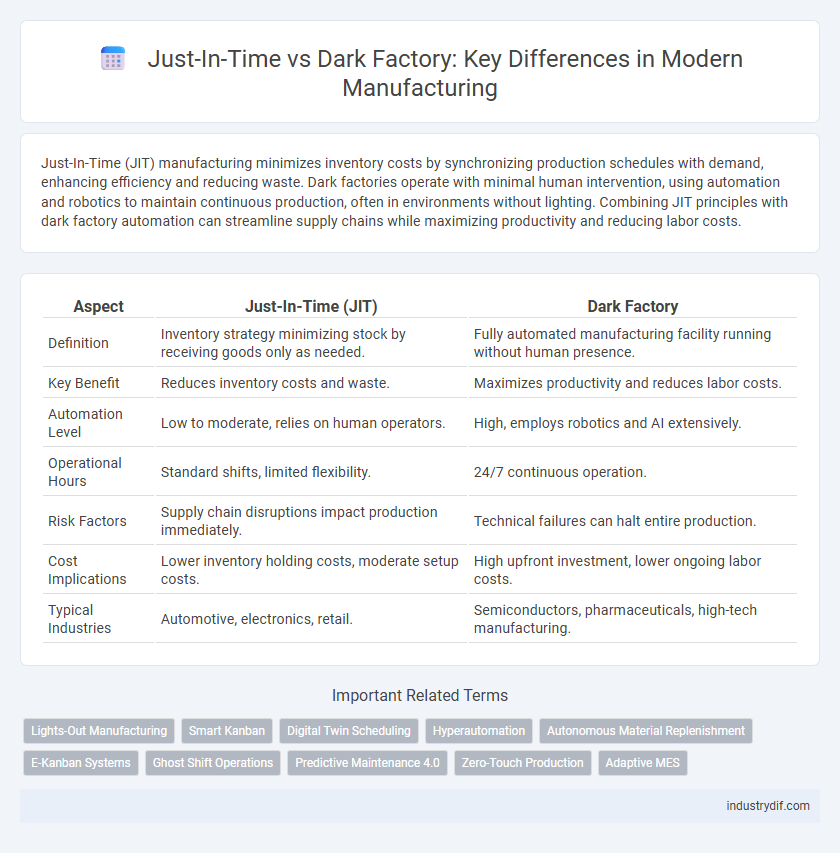

| Aspect | Just-In-Time (JIT) | Dark Factory |

|---|---|---|

| Definition | Inventory strategy minimizing stock by receiving goods only as needed. | Fully automated manufacturing facility running without human presence. |

| Key Benefit | Reduces inventory costs and waste. | Maximizes productivity and reduces labor costs. |

| Automation Level | Low to moderate, relies on human operators. | High, employs robotics and AI extensively. |

| Operational Hours | Standard shifts, limited flexibility. | 24/7 continuous operation. |

| Risk Factors | Supply chain disruptions impact production immediately. | Technical failures can halt entire production. |

| Cost Implications | Lower inventory holding costs, moderate setup costs. | High upfront investment, lower ongoing labor costs. |

| Typical Industries | Automotive, electronics, retail. | Semiconductors, pharmaceuticals, high-tech manufacturing. |

Understanding Just-In-Time Manufacturing

Just-In-Time (JIT) manufacturing optimizes production by minimizing inventory levels and delivering materials only as they are needed, reducing waste and increasing efficiency. This method relies heavily on precise demand forecasting and strong supplier relationships to synchronize the supply chain with production schedules. Compared to Dark Factory automation, which emphasizes fully unmanned operations, JIT focuses on lean process management and timely resource allocation to streamline manufacturing workflows.

What Is a Dark Factory?

A Dark Factory refers to a fully automated manufacturing facility that operates without human presence on-site, utilizing advanced robotics, AI, and IoT systems to maintain continuous production. This approach minimizes labor costs, reduces errors, and enhances efficiency by allowing 24/7 operation under controlled conditions. Unlike Just-In-Time manufacturing, which focuses on inventory reduction and timely production flow, Dark Factories emphasize automation and resilience through autonomous processes.

Key Principles of Just-In-Time Production

Just-In-Time (JIT) production is centered on minimizing inventory by synchronizing raw material arrival with production schedules, reducing waste and storage costs. It emphasizes continuous flow, pull-based demand-driven manufacturing, and a strong supplier relationship to ensure timely delivery of components. JIT enhances efficiency by promoting quality control at every stage and flexible workforce deployment, contrasting with the automation-heavy, unmanned operations typical of dark factories.

Dark Factory: Automation and Lights-Out Operations

Dark Factory leverages full automation and lights-out operations to achieve continuous, efficient production without human intervention, significantly reducing labor costs and minimizing errors. This advanced manufacturing approach utilizes robotics, AI-driven systems, and IoT sensors to monitor and control processes in real-time, ensuring optimal resource use and maximum uptime. Compared to Just-In-Time methods, Dark Factory improves scalability and resilience against supply chain disruptions by operating independently of traditional workforce constraints.

Benefits of Just-In-Time Manufacturing

Just-In-Time (JIT) manufacturing significantly reduces inventory costs by synchronizing production schedules with demand, minimizing waste and storage expenses. It enhances operational efficiency through streamlined workflows and quicker response times to market changes. By lowering excess stock, JIT improves cash flow and reduces the risk of obsolete inventory in manufacturing environments.

Advantages of Fully Automated Dark Factories

Fully automated dark factories significantly reduce labor costs and human error by operating 24/7 without the need for lighting or breaks, maximizing production efficiency. They enhance precision and consistency through advanced robotics and AI, leading to higher product quality and reduced waste. Real-time data analytics optimize maintenance and workflow, resulting in minimal downtime and greater responsiveness to market demand.

Challenges of Implementing JIT vs Dark Factory

Implementing Just-In-Time (JIT) manufacturing faces challenges such as dependency on precise supplier coordination, vulnerability to supply chain disruptions, and high inventory risks. Dark Factory automation confronts obstacles including significant upfront capital investment, complex integration of robotics and AI technologies, and the need for skilled personnel to manage unmanned operations. Both systems require robust infrastructure, but JIT struggles more with external factors while Dark Factory emphasizes internal technological and workforce challenges.

Comparing Operational Efficiency: JIT vs Dark Factory

Just-In-Time (JIT) manufacturing minimizes inventory costs by synchronizing production schedules with demand, enhancing operational efficiency through reduced waste and faster turnaround times. Dark Factory leverages automation and robotics to operate 24/7 without human intervention, significantly boosting productivity and consistency while lowering labor costs. Comparing these approaches, JIT excels in demand-driven efficiency and flexibility, whereas Dark Factories offer superior output reliability and scalability in high-volume manufacturing environments.

Impact on Workforce and Skill Requirements

Just-In-Time manufacturing reduces workforce size by minimizing inventory handling and emphasizing cross-trained employees capable of rapid problem-solving and multitasking. Dark Factories rely heavily on automation and robotics, drastically reducing human labor needs and shifting skill requirements toward programming, maintenance, and systems integration. The transition from Just-In-Time to Dark Factories demands workforce reskilling to advanced technical expertise in AI-driven equipment and cyber-physical systems.

Future Trends: Integrating JIT and Dark Factory Approaches

Future trends in manufacturing emphasize the integration of Just-In-Time (JIT) production with Dark Factory automation to maximize efficiency and reduce operational costs. Combining JIT's demand-driven inventory management with the autonomous, 24/7 capabilities of Dark Factories enables real-time responsiveness and minimal waste. This hybrid approach leverages advanced robotics, AI, and IoT to create highly adaptive production environments tailored for Industry 4.0.

Related Important Terms

Lights-Out Manufacturing

Lights-out manufacturing thrives in dark factories by leveraging Just-In-Time (JIT) principles to minimize inventory and reduce waste, enabling fully automated, 24/7 production without human intervention. This integration enhances efficiency and responsiveness, allowing manufacturers to optimize supply chain synchronization and adapt swiftly to demand fluctuations.

Smart Kanban

Smart Kanban enhances Just-In-Time manufacturing by optimizing inventory flow through real-time data and automated replenishment, reducing waste and improving production efficiency. In contrast, Dark Factories leverage Smart Kanban systems within fully automated environments to maintain continuous operations without human intervention, maximizing uptime and minimizing downtime.

Digital Twin Scheduling

Just-In-Time manufacturing streamlines production by synchronizing inventory with demand, minimizing waste and reducing lead times through precise scheduling algorithms. Dark Factory leverages Digital Twin technology to simulate and optimize fully automated, human-free production environments, enabling real-time adjustments and maximizing operational efficiency.

Hyperautomation

Hyperautomation integrates Just-In-Time manufacturing principles with Dark Factory environments by leveraging AI-driven robotics and real-time data analytics to optimize inventory management and production workflows. This synergy minimizes waste and downtime while maximizing operational efficiency through fully automated, 24/7 unmanned manufacturing processes.

Autonomous Material Replenishment

Just-In-Time manufacturing relies on precise timing and human coordination for material replenishment, whereas Dark Factory systems utilize autonomous robots and AI-driven inventory management to enable continuous, unmanned production. Autonomous Material Replenishment in Dark Factories reduces downtime and optimizes supply chain efficiency by dynamically adjusting inventory levels based on real-time data analytics.

E-Kanban Systems

E-Kanban systems streamline inventory management by enabling real-time communication between production stages, crucial for Just-In-Time manufacturing to reduce waste and minimize stock levels. In Dark Factory environments, E-Kanban integrates automated signals with robotic workflows to maintain continuous production without human intervention, enhancing efficiency and precision.

Ghost Shift Operations

Just-In-Time manufacturing emphasizes minimizing inventory by synchronizing production with demand, while Dark Factory leverages fully automated Ghost Shift Operations to run continuous, unattended production cycles during off-hours, enhancing efficiency and reducing labor costs. Ghost Shift Operations utilize robotics and AI-driven systems to maintain productivity without human intervention, enabling 24/7 manufacturing with increased precision and minimal downtime.

Predictive Maintenance 4.0

Predictive Maintenance 4.0 leverages real-time IoT sensor data and AI analytics to optimize equipment uptime in both Just-In-Time manufacturing and Dark Factory environments. Its advanced failure prediction models reduce unplanned downtime by enabling proactive maintenance scheduling, increasing operational efficiency and minimizing inventory costs.

Zero-Touch Production

Zero-touch production in Just-In-Time manufacturing emphasizes minimal human intervention by synchronizing inventory flow precisely to demand, reducing waste and lead times. Dark factories integrate zero-touch principles through full automation and robotics, enabling continuous, lights-out operations that optimize efficiency and lower labor costs.

Adaptive MES

Adaptive MES integrates Just-In-Time principles with Dark Factory automation by dynamically optimizing production schedules and real-time resource allocation, reducing inventory costs and minimizing human intervention. This synergy enhances operational efficiency, supports zero-defect manufacturing, and enables rapid response to demand fluctuations through AI-driven predictive analytics.

Just-In-Time vs Dark Factory Infographic

industrydif.com

industrydif.com