Supply chain optimization enhances efficiency by minimizing costs and improving delivery timelines through streamlined processes and data-driven decision making. Circular supply chain models prioritize sustainability by focusing on resource reuse, waste reduction, and product lifecycle extension to create closed-loop systems. Integrating circular principles into supply chain optimization drives both economic performance and environmental responsibility in manufacturing.

Table of Comparison

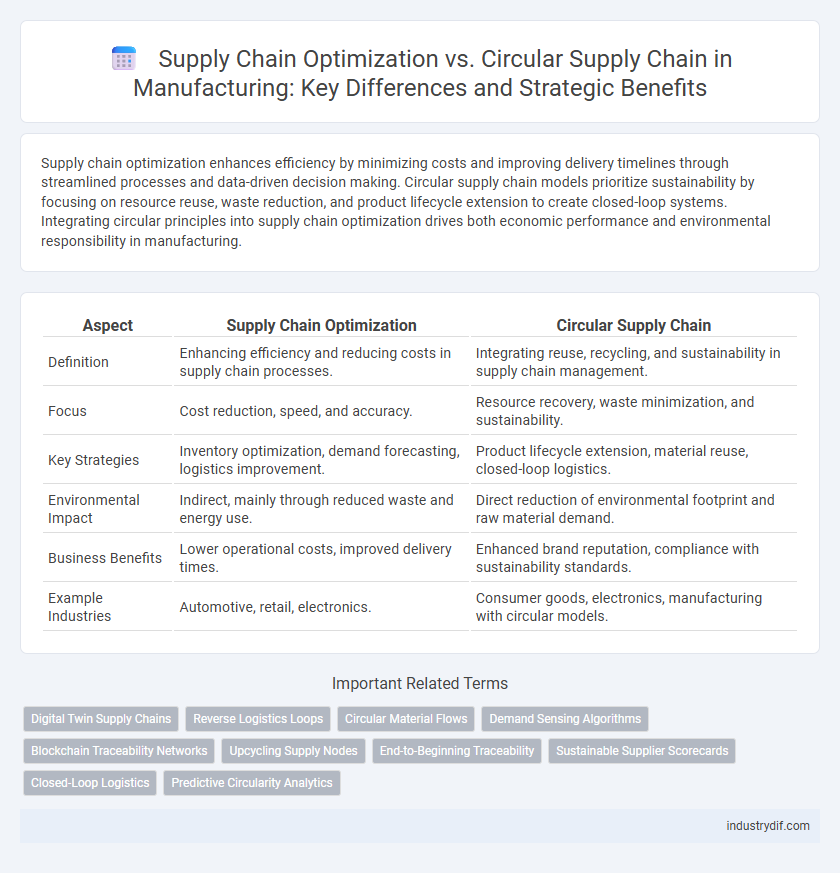

| Aspect | Supply Chain Optimization | Circular Supply Chain |

|---|---|---|

| Definition | Enhancing efficiency and reducing costs in supply chain processes. | Integrating reuse, recycling, and sustainability in supply chain management. |

| Focus | Cost reduction, speed, and accuracy. | Resource recovery, waste minimization, and sustainability. |

| Key Strategies | Inventory optimization, demand forecasting, logistics improvement. | Product lifecycle extension, material reuse, closed-loop logistics. |

| Environmental Impact | Indirect, mainly through reduced waste and energy use. | Direct reduction of environmental footprint and raw material demand. |

| Business Benefits | Lower operational costs, improved delivery times. | Enhanced brand reputation, compliance with sustainability standards. |

| Example Industries | Automotive, retail, electronics. | Consumer goods, electronics, manufacturing with circular models. |

Introduction to Supply Chain Optimization

Supply Chain Optimization enhances manufacturing efficiency by streamlining procurement, production, and distribution processes to reduce costs and improve delivery times. It utilizes advanced analytics and automation to forecast demand accurately and manage inventory levels effectively. Circular Supply Chain builds on this by integrating sustainable practices like recycling and resource reuse to minimize waste and promote environmental responsibility.

Defining the Circular Supply Chain Concept

Circular supply chain redefines traditional supply chain optimization by prioritizing resource efficiency, waste reduction, and product lifecycle extension. It integrates principles of reuse, recycling, and regeneration within manufacturing processes to create closed-loop systems that minimize environmental impact. This approach shifts focus from linear resource consumption to sustainable value creation, driving innovation in material sourcing, product design, and logistics management.

Key Principles of Traditional Supply Chain Optimization

Traditional supply chain optimization focuses on maximizing efficiency through demand forecasting, inventory management, and streamlined logistics to reduce costs and improve delivery times. Key principles include lean manufacturing practices, just-in-time inventory systems, and supplier relationship management to minimize waste and enhance responsiveness. Emphasis is placed on linear flows of materials and information, prioritizing cost savings and operational efficiency over sustainability or resource recovery.

Core Elements of Circular Supply Chains

Circular supply chains emphasize core elements such as resource recirculation, waste minimization, and product lifecycle extension, leveraging reverse logistics and remanufacturing to close material loops. Unlike traditional supply chain optimization that focuses on cost efficiency and speed, circular models prioritize sustainability by incorporating renewable inputs and designing for reuse and recyclability. Key strategies include integrating closed-loop systems, enhancing collaboration among stakeholders, and employing digital technologies for real-time tracking and transparency.

Comparative Value Propositions

Supply Chain Optimization emphasizes efficiency, cost reduction, and streamlined logistics to maximize profitability and minimize waste in manufacturing processes. Circular Supply Chain prioritizes sustainability by integrating reuse, recycling, and regenerative practices to reduce environmental impact and enhance resource longevity. The comparative value proposition lies in balancing operational efficiency with ecological responsibility, where traditional optimization drives immediate economic gains while circular models foster long-term resilience and compliance with evolving environmental regulations.

Technological Innovations Driving Both Models

Technological innovations such as IoT sensors, AI-driven analytics, and blockchain are revolutionizing supply chain optimization by enhancing real-time visibility and predictive accuracy in inventory management. In circular supply chains, advanced recycling technologies, digital twins, and smart material tracking enable efficient resource recovery and product lifecycle extension. Both models leverage automation, data integration, and cloud computing to improve sustainability, reduce costs, and increase responsiveness across manufacturing supply networks.

Environmental and Economic Impacts

Supply chain optimization primarily focuses on improving efficiency, reducing costs, and minimizing waste through streamlined logistics and inventory management, yielding significant economic benefits such as lower operational expenses and increased profitability. In contrast, circular supply chains emphasize resource reuse, recycling, and regeneration to minimize environmental impact by reducing landfill contributions and carbon emissions. Integrating circular supply chain principles can enhance long-term sustainability and resilience while supporting economic objectives through material cost savings and compliance with environmental regulations.

Challenges in Implementation and Scalability

Supply chain optimization faces challenges such as demand forecasting inaccuracies, inventory management complexities, and supplier coordination issues that can hinder scalability. Circular supply chains encounter implementation barriers including resource recovery inefficiencies, product redesign requirements, and regulatory compliance, which complicate expansion efforts. Both approaches require robust technology integration and stakeholder collaboration to overcome these operational obstacles and achieve scalable solutions.

Industry Case Studies: Linear vs. Circular Successes

Industry case studies reveal that supply chain optimization in linear models drives efficiency through streamlined procurement, production, and distribution, exemplified by companies like Toyota achieving reduced lead times and cost savings. Circular supply chain successes, such as IKEA's use of recycled materials and product life extension, demonstrate significant waste reduction and enhanced sustainability metrics. Data from these cases highlight improved resource utilization and lower environmental impact in circular models compared to traditional linear supply chains.

Future Trends in Supply Chain Management

Future trends in supply chain management highlight a shift from traditional supply chain optimization, which emphasizes cost reduction and efficiency, toward circular supply chains that prioritize sustainability and resource regeneration. Advanced technologies like AI, IoT, and blockchain enable real-time data analytics and traceability, supporting closed-loop systems that minimize waste and promote product lifecycle extension. Companies adopting circular supply chains can achieve competitive advantages through enhanced brand reputation, regulatory compliance, and resilience against market disruptions.

Related Important Terms

Digital Twin Supply Chains

Digital Twin Supply Chains enhance supply chain optimization by creating real-time virtual replicas that enable predictive analytics and proactive decision-making, reducing costs and improving efficiency. In circular supply chains, Digital Twins facilitate resource recovery and waste minimization by simulating product life cycles and supporting closed-loop systems for sustainable manufacturing.

Reverse Logistics Loops

Supply chain optimization enhances efficiency by streamlining forward logistics, while circular supply chains emphasize reverse logistics loops to recover, refurbish, and recycle materials, minimizing waste and extending product lifecycle. Integrating advanced tracking technologies and data analytics in reverse logistics enables manufacturers to optimize returns processing and resource recirculation, driving sustainability and cost savings.

Circular Material Flows

Circular supply chains prioritize closed-loop material flows that maximize resource recovery and minimize waste, contrasting with traditional supply chain optimization that often focuses on cost efficiency and speed. By integrating circular material flows, manufacturers enhance sustainability through continuous reuse, remanufacturing, and recycling processes that reduce environmental impact and promote long-term resource resilience.

Demand Sensing Algorithms

Demand sensing algorithms in supply chain optimization enable real-time inventory adjustments by analyzing demand signals, reducing stockouts and excess inventory. In circular supply chains, these algorithms enhance product lifecycle management by forecasting returns and reusability, promoting sustainable resource utilization.

Blockchain Traceability Networks

Supply Chain Optimization leverages blockchain traceability networks to enhance transparency, reduce inefficiencies, and improve real-time data sharing across manufacturing processes, ensuring accurate tracking of materials and products. Circular Supply Chain integrates blockchain technology to enable closed-loop systems by verifying product lifecycle stages, facilitating resource recovery, and promoting sustainable manufacturing practices through immutable, decentralized records.

Upcycling Supply Nodes

Supply chain optimization streamlines workflows to reduce costs and improve efficiency by minimizing waste and enhancing resource allocation, while circular supply chain models prioritize upcycling supply nodes to extend product life cycles and promote sustainable material reuse. Integrating upcycling supply nodes into circular supply chains transforms traditional linear processes into regenerative systems that reduce environmental impact and create added economic value through resource recovery.

End-to-Beginning Traceability

Supply chain optimization enhances operational efficiency by streamlining processes and reducing costs through real-time visibility and predictive analytics, while circular supply chains prioritize end-to-beginning traceability to enable product reuse, remanufacturing, and resource recovery. Emphasizing reverse logistics and lifecycle data integration, circular supply chains foster sustainability and resilience by tracking materials from consumption back to raw material sourcing.

Sustainable Supplier Scorecards

Supply chain optimization enhances efficiency by streamlining logistics and reducing costs, while circular supply chains prioritize resource reuse and waste minimization to boost sustainability. Sustainable supplier scorecards evaluate environmental impact, social responsibility, and governance metrics, enabling manufacturers to integrate eco-friendly practices and improve supply chain transparency.

Closed-Loop Logistics

Supply chain optimization focuses on improving efficiency and cost-effectiveness through streamlined processes and demand forecasting, while circular supply chain emphasizes closed-loop logistics that reintegrate products and materials back into the production cycle to minimize waste. Closed-loop logistics enables manufacturers to recover valuable resources, reduce environmental impact, and drive sustainability by facilitating reverse flows of goods, remanufacturing, and recycling within the supply chain.

Predictive Circularity Analytics

Supply Chain Optimization leverages data-driven strategies to enhance efficiency, reduce costs, and improve delivery timelines by forecasting demand and managing inventory levels. Predictive Circularity Analytics in Circular Supply Chain models advance sustainability by analyzing material flows and waste patterns to forecast resource recovery, enabling closed-loop systems that minimize environmental impact and extend product lifecycles.

Supply Chain Optimization vs Circular Supply Chain Infographic

industrydif.com

industrydif.com