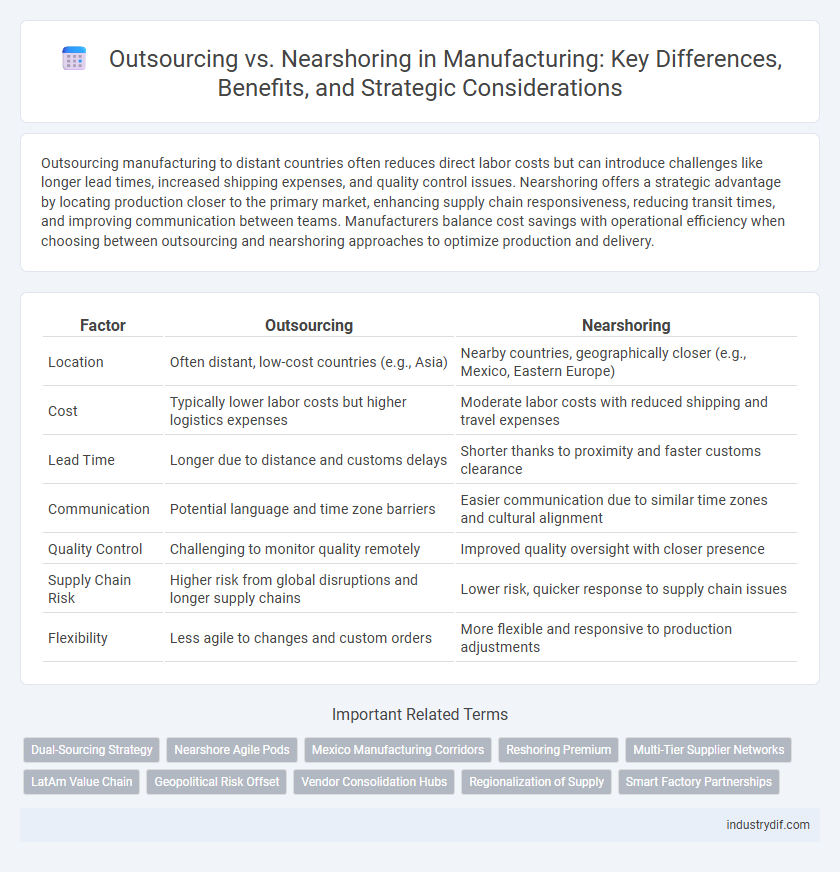

Outsourcing manufacturing to distant countries often reduces direct labor costs but can introduce challenges like longer lead times, increased shipping expenses, and quality control issues. Nearshoring offers a strategic advantage by locating production closer to the primary market, enhancing supply chain responsiveness, reducing transit times, and improving communication between teams. Manufacturers balance cost savings with operational efficiency when choosing between outsourcing and nearshoring approaches to optimize production and delivery.

Table of Comparison

| Factor | Outsourcing | Nearshoring |

|---|---|---|

| Location | Often distant, low-cost countries (e.g., Asia) | Nearby countries, geographically closer (e.g., Mexico, Eastern Europe) |

| Cost | Typically lower labor costs but higher logistics expenses | Moderate labor costs with reduced shipping and travel expenses |

| Lead Time | Longer due to distance and customs delays | Shorter thanks to proximity and faster customs clearance |

| Communication | Potential language and time zone barriers | Easier communication due to similar time zones and cultural alignment |

| Quality Control | Challenging to monitor quality remotely | Improved quality oversight with closer presence |

| Supply Chain Risk | Higher risk from global disruptions and longer supply chains | Lower risk, quicker response to supply chain issues |

| Flexibility | Less agile to changes and custom orders | More flexible and responsive to production adjustments |

Understanding Outsourcing in Manufacturing

Outsourcing in manufacturing involves delegating production processes to third-party suppliers, often located in countries with lower labor costs to reduce expenses and increase efficiency. This strategy allows companies to focus on core competencies while leveraging specialized expertise and scalable resources from external partners. Key considerations include quality control, intellectual property protection, and supply chain reliability to ensure consistent product standards and timely delivery.

Defining Nearshoring in Industrial Context

Nearshoring in industrial manufacturing refers to relocating production processes to nearby countries to reduce lead times, transportation costs, and improve supply chain responsiveness. It enhances flexibility by enabling closer collaboration and faster adaptation to market changes compared to traditional outsourcing in distant regions. This strategy helps manufacturers optimize operational efficiency while maintaining quality control and minimizing geopolitical risks.

Key Differences Between Outsourcing and Nearshoring

Outsourcing involves delegating manufacturing tasks to third-party providers, often in distant countries with cost-effective labor, whereas nearshoring relocates production closer to the company's home country, enhancing supply chain transparency and reducing logistics costs. Key differences include geographic proximity, with outsourcing typically offshored far away and nearshoring situated in neighboring or nearby countries, leading to shorter lead times and improved communication. Additionally, nearshoring offers greater control over quality and compliance with local regulations, which can be challenging to manage in traditional outsourcing models.

Cost Implications: Outsourcing vs Nearshoring

Outsourcing manufacturing to low-cost countries often reduces labor expenses but can increase logistics and quality control costs, impacting overall savings. Nearshoring lowers transportation expenses and shortens supply chains, resulting in faster turnaround times and reduced inventory costs. Companies must weigh these cost implications against factors such as tariff risks, currency fluctuations, and lead time reliability to optimize their manufacturing strategy.

Quality Control and Production Oversight

Outsourcing manufacturing to distant locations often complicates quality control due to time zone differences and limited onsite supervision, increasing the risk of defects and delays. Nearshoring enhances production oversight by enabling closer proximity to suppliers, facilitating real-time communication, frequent audits, and quicker response to quality issues. Companies leveraging nearshoring report improved product consistency and tighter compliance with industry standards compared to remote outsourcing models.

Supply Chain Efficiency and Logistics

Outsourcing manufacturing to distant countries often reduces direct production costs but increases supply chain complexity and lead times due to extended logistics, customs clearance, and potential geopolitical risks. Nearshoring enhances supply chain efficiency by shortening transit times, improving communication, and enabling faster responsiveness to market changes, which reduces inventory holding costs and mitigates supply disruptions. Companies that prioritize supply chain agility benefit from nearshoring as it streamlines logistics, lowers transportation expenses, and supports just-in-time manufacturing strategies.

Intellectual Property and Data Security Concerns

Outsourcing manufacturing to distant countries often raises significant intellectual property (IP) and data security risks due to varying legal frameworks and enforcement levels. Nearshoring offers enhanced control over IP protection and data security, leveraging proximity, shared regulations, and cultural alignment to mitigate potential breaches. Companies prioritizing confidentiality and proprietary technology increasingly favor nearshoring to safeguard critical innovations and sensitive data assets.

Workforce Skills and Labor Availability

Outsourcing manufacturing often provides access to a larger pool of specialized workforce skills in countries with established industrial expertise, enhancing production quality and innovation. Nearshoring offers the advantage of closer geographic proximity, enabling faster communication and easier management of skilled labor with familiar cultural and regulatory environments. Labor availability nearshore typically benefits from aligned time zones and reduced logistical complexities, supporting agile supply chain responsiveness.

Risk Management in Global Manufacturing

Outsourcing in global manufacturing often exposes companies to risks such as geopolitical instability, longer supply chains, and communication barriers, which can disrupt production and increase costs. Nearshoring reduces risk by situating supply chains closer to the home market, improving responsiveness and traceability while mitigating currency fluctuations and customs delays. Effective risk management requires balancing cost savings with operational resilience, prioritizing suppliers with robust compliance standards and transparent logistics.

Strategic Considerations for Choosing the Right Model

Strategic considerations for choosing between outsourcing and nearshoring in manufacturing involve evaluating cost efficiency, supply chain resilience, and market responsiveness. Outsourcing often offers lower labor costs and scalability, while nearshoring enhances proximity to key markets, reduces lead times, and improves communication. Companies must align their decision with goals such as risk management, quality control, and customer demand dynamics to optimize operational performance.

Related Important Terms

Dual-Sourcing Strategy

A dual-sourcing strategy in manufacturing balances outsourcing to low-cost countries with nearshoring partners to enhance supply chain resilience and reduce lead times. Leveraging this hybrid approach maximizes cost efficiency while ensuring flexibility and risk mitigation against geopolitical disruptions.

Nearshore Agile Pods

Nearshore agile pods in manufacturing enable companies to accelerate product development cycles by leveraging local talent pools and reducing communication barriers. These pods facilitate real-time collaboration and rapid iteration, enhancing flexibility and responsiveness compared to traditional outsourcing models.

Mexico Manufacturing Corridors

Mexico Manufacturing Corridors offer cost-effective nearshoring options with reduced lead times and proximity to U.S. markets, enhancing supply chain agility compared to traditional outsourcing. These corridors leverage skilled labor pools, robust infrastructure, and favorable trade agreements to optimize manufacturing efficiency and minimize logistics expenses.

Reshoring Premium

Outsourcing manufacturing to distant countries often lowers immediate costs but increases logistical complexity and time-to-market, whereas nearshoring reduces supply chain risks and supports faster response to market changes, commanding a reshoring premium due to proximity and agility advantages. The reshoring premium reflects higher labor costs offset by improved quality control, reduced transportation expenses, and enhanced innovation through closer collaboration with local suppliers.

Multi-Tier Supplier Networks

Multi-tier supplier networks in manufacturing benefit from nearshoring by reducing lead times and enhancing supply chain visibility compared to outsourcing overseas suppliers. Nearshoring enables closer collaboration across multiple supplier tiers, improving quality control and responsiveness to market fluctuations.

LatAm Value Chain

Outsourcing manufacturing to LatAm offers cost-effective labor and proximity advantages that enhance supply chain agility, while nearshoring within the region reduces lead times and mitigates risks associated with long-haul logistics. Leveraging LatAm's integrated value chain, companies benefit from streamlined operations, lower tariffs under trade agreements like USMCA, and access to skilled labor pools in Mexico, Brazil, and Colombia, optimizing production efficiency and market responsiveness.

Geopolitical Risk Offset

Nearshoring strategically mitigates geopolitical risk by relocating manufacturing closer to domestic markets, reducing exposure to trade tariffs and international supply chain disruptions common in traditional outsourcing to distant countries. This proximity enhances supply chain resilience, lowers transportation costs, and ensures more agile responses to regulatory changes compared to offshore outsourcing.

Vendor Consolidation Hubs

Vendor consolidation hubs streamline supply chains by centralizing multiple outsourced manufacturing partners into a single geographic location, reducing logistics complexity and improving lead times. Nearshoring these hubs enhances responsiveness and lowers transportation costs compared to traditional offshore outsourcing, enabling manufacturers to better manage inventory and maintain quality control.

Regionalization of Supply

Nearshoring enhances regional supply chain resilience by reducing transit times and transportation costs compared to outsourcing, which often relies on distant, less flexible suppliers. This regionalization strategy supports faster response to market fluctuations, improved communication, and greater control over production quality within the manufacturing sector.

Smart Factory Partnerships

Smart factory partnerships leverage nearshoring to enhance manufacturing agility by situating advanced production close to key markets, reducing lead times, and optimizing supply chain responsiveness. Outsourcing often offers cost advantages but can increase risks in quality control and logistics complexity, making nearshoring with smart factory integration a strategic choice for innovation-driven manufacturers.

Outsourcing vs Nearshoring Infographic

industrydif.com

industrydif.com