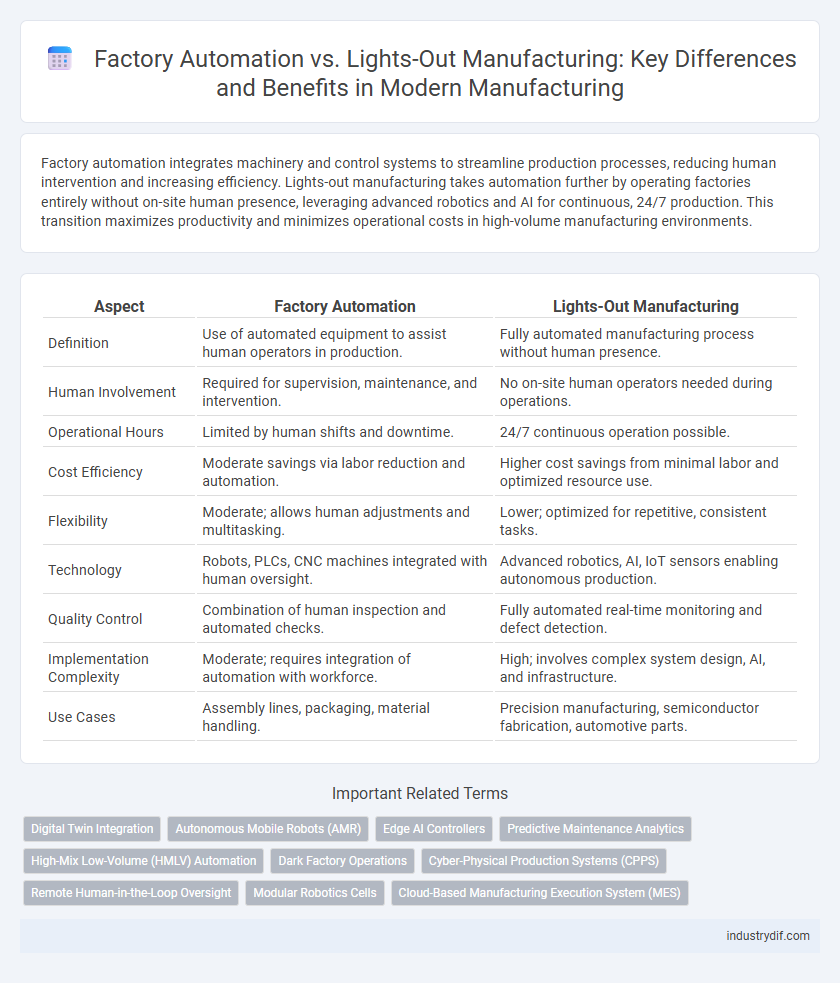

Factory automation integrates machinery and control systems to streamline production processes, reducing human intervention and increasing efficiency. Lights-out manufacturing takes automation further by operating factories entirely without on-site human presence, leveraging advanced robotics and AI for continuous, 24/7 production. This transition maximizes productivity and minimizes operational costs in high-volume manufacturing environments.

Table of Comparison

| Aspect | Factory Automation | Lights-Out Manufacturing |

|---|---|---|

| Definition | Use of automated equipment to assist human operators in production. | Fully automated manufacturing process without human presence. |

| Human Involvement | Required for supervision, maintenance, and intervention. | No on-site human operators needed during operations. |

| Operational Hours | Limited by human shifts and downtime. | 24/7 continuous operation possible. |

| Cost Efficiency | Moderate savings via labor reduction and automation. | Higher cost savings from minimal labor and optimized resource use. |

| Flexibility | Moderate; allows human adjustments and multitasking. | Lower; optimized for repetitive, consistent tasks. |

| Technology | Robots, PLCs, CNC machines integrated with human oversight. | Advanced robotics, AI, IoT sensors enabling autonomous production. |

| Quality Control | Combination of human inspection and automated checks. | Fully automated real-time monitoring and defect detection. |

| Implementation Complexity | Moderate; requires integration of automation with workforce. | High; involves complex system design, AI, and infrastructure. |

| Use Cases | Assembly lines, packaging, material handling. | Precision manufacturing, semiconductor fabrication, automotive parts. |

Understanding Factory Automation: Key Concepts

Factory automation encompasses integrating control systems such as robots, sensors, and computer software to manage manufacturing processes with minimal human intervention. Key concepts include programmable logic controllers (PLCs), real-time monitoring, and automated material handling, which streamline production efficiency and quality control. These technologies form the foundation for more advanced models like lights-out manufacturing, where factories operate fully autonomously without onsite personnel.

Defining Lights-Out Manufacturing in Modern Industry

Lights-out manufacturing refers to fully automated factory operations that require no human presence on-site, utilizing robotics, IoT sensors, and AI-driven systems to maintain continuous production. This advanced approach enables manufacturers to achieve higher efficiency, reduced operational costs, and minimal error rates compared to traditional factory automation. By integrating real-time data analytics and autonomous machinery, lights-out manufacturing represents a transformational shift toward smart factories in Industry 4.0.

Core Technologies Driving Factory Automation

Core technologies driving factory automation include industrial robotics, programmable logic controllers (PLCs), and machine vision systems, which enhance precision and efficiency in production lines. These technologies enable real-time data collection and analysis through IoT integration, facilitating predictive maintenance and minimizing downtime. In contrast, lights-out manufacturing builds on these foundations by implementing fully autonomous systems with advanced AI and sensor networks to operate factories with minimal or no human intervention.

Essential Components of Lights-Out Manufacturing

Lights-out manufacturing relies on fully automated systems, including robotic arms, automated guided vehicles (AGVs), and integrated sensor networks, to operate without human intervention. Essential components also encompass advanced AI-driven control software, real-time data analytics, and IoT-enabled machinery to ensure seamless production and rapid fault detection. Robust communication protocols and predictive maintenance technologies enable continuous, unattended operations, dramatically improving efficiency and reducing labor costs.

Comparing Human Involvement: Automation vs Lights-Out

Factory automation integrates human oversight with machine operations, allowing operators to monitor, intervene, and optimize production processes as needed; in contrast, lights-out manufacturing eliminates direct human involvement on the production floor by relying entirely on autonomous robotic systems and AI-driven controls. Automated factories benefit from human expertise to manage exceptions and complex decision-making, whereas lights-out facilities prioritize continuous, uninterrupted production with minimal risk of human error or downtime caused by shift changes. The degree of human involvement distinguishes these models, with factory automation enhancing human-machine collaboration and lights-out manufacturing achieving maximum efficiency through full automation.

Production Efficiency: Factory Automation vs Lights-Out Operations

Factory automation streamlines production by integrating machinery and control systems to reduce human intervention, boosting output consistency and minimizing errors. Lights-out manufacturing takes this further by operating fully automated factories without onsite personnel, enabling 24/7 production and dramatically increasing operational uptime. Both approaches enhance production efficiency, but lights-out manufacturing maximizes utilization rates by eliminating downtime associated with human shifts and manual oversight.

Cost Implications and ROI Analysis

Factory automation requires significant upfront capital investment in robotics, control systems, and software integration, with moderate ongoing maintenance costs, leading to ROI typically realized within 2 to 4 years. Lights-out manufacturing, characterized by fully automated, unmanned facilities, demands higher initial expenditure on advanced AI, sensors, and reliable fail-safes, but offers drastically reduced labor costs and increased production efficiency, potentially accelerating ROI to under 2 years. Cost implications favor lights-out manufacturing for long-term scalability and competitiveness, while traditional factory automation suits firms prioritizing gradual tech integration and lower immediate financial risk.

Scalability and Flexibility in Manufacturing Processes

Factory automation enhances scalability by integrating programmable machinery that adapts to varying production volumes, offering moderate flexibility for diverse product lines. Lights-out manufacturing achieves higher scalability through fully autonomous systems operating without human intervention, enabling continuous, high-volume production with minimal downtime. While factory automation supports flexible task adjustments and rapid changeovers, lights-out manufacturing prioritizes efficiency and consistency, often trading some flexibility for maximum scalability and operational precision.

Challenges and Limitations of Each Approach

Factory automation faces challenges such as high initial investment costs, complex system integration, and workforce skill gaps that hinder seamless operation. Lights-out manufacturing, while offering continuous production without human intervention, struggles with limited flexibility in handling product variations and requires advanced predictive maintenance to prevent costly downtime. Both approaches demand robust cybersecurity measures and reliable sensor networks to ensure operational safety and data integrity.

Future Trends: Integrating Automation Toward Fully Lights-Out Facilities

Future trends in factory automation emphasize the integration of advanced robotics, AI-driven control systems, and IoT connectivity to achieve fully lights-out manufacturing facilities. These technologies enable continuous, autonomous production with minimal human intervention, enhancing efficiency, reducing errors, and lowering operational costs. Investment in predictive maintenance and machine learning algorithms drives the shift toward seamless, self-optimizing factories that operate 24/7 without on-site personnel.

Related Important Terms

Digital Twin Integration

Factory automation enhances operational efficiency by integrating robotic systems and sensors to streamline repetitive tasks, while lights-out manufacturing pushes this further by enabling fully autonomous production without human intervention. Digital twin integration plays a critical role by creating virtual replicas of physical assets, allowing real-time monitoring, predictive maintenance, and process optimization to maximize productivity and minimize downtime.

Autonomous Mobile Robots (AMR)

Factory automation integrates Autonomous Mobile Robots (AMRs) to streamline repetitive tasks, enhance workflow efficiency, and reduce human intervention, primarily in mixed human-robot environments. Lights-out manufacturing relies heavily on AMRs for fully autonomous operations with minimal to no human presence, maximizing continuous production and operational uptime.

Edge AI Controllers

Edge AI controllers enable factory automation by integrating real-time data processing and adaptive machine learning at the production line, enhancing efficiency and reducing downtime. In lights-out manufacturing, these controllers support fully autonomous operations by managing robotics and predictive maintenance without human intervention, driving continuous, high-precision output.

Predictive Maintenance Analytics

Predictive maintenance analytics in factory automation uses real-time sensor data and machine learning algorithms to forecast equipment failures, minimizing downtime and optimizing production efficiency. In lights-out manufacturing, these predictive insights enable fully autonomous operations by ensuring continuous, uninterrupted machine performance without human intervention.

High-Mix Low-Volume (HMLV) Automation

Factory automation in High-Mix Low-Volume (HMLV) manufacturing focuses on flexible machinery and adaptable processes to handle diverse product variants efficiently. Lights-out manufacturing enhances HMLV operations by enabling fully autonomous production with minimal human intervention, improving precision and reducing downtime in complex, small-batch production environments.

Dark Factory Operations

Dark factory operations represent a fully autonomous manufacturing environment where machines operate without human intervention, enhancing productivity and reducing labor costs. Unlike general factory automation, which involves human oversight, lights-out manufacturing relies on integrated robotics, AI, and IoT technologies to maintain continuous, uninterrupted production even in complete darkness.

Cyber-Physical Production Systems (CPPS)

Factory automation integrates machines and control systems to streamline production processes, while Lights-Out Manufacturing relies on fully autonomous operations without human intervention, maximizing efficiency. Cyber-Physical Production Systems (CPPS) serve as the core enablers by merging physical manufacturing assets with digital information technology, facilitating real-time communication, monitoring, and adaptive control across both methods.

Remote Human-in-the-Loop Oversight

Factory automation integrates programmable machinery to perform tasks with minimal human intervention, while lights-out manufacturing operates entirely unmanned, leveraging advanced robotics and AI systems. Remote human-in-the-loop oversight in lights-out manufacturing enhances system reliability by enabling real-time monitoring, anomaly detection, and intervention from off-site experts.

Modular Robotics Cells

Modular robotics cells in factory automation enhance flexibility by integrating customizable robotic units that adapt to diverse manufacturing tasks, improving efficiency and reducing downtime. Lights-out manufacturing leverages these cells for fully autonomous, unmanned operations, maximizing productivity while minimizing human intervention and operational costs.

Cloud-Based Manufacturing Execution System (MES)

Cloud-based Manufacturing Execution Systems (MES) enable real-time data integration and remote monitoring, streamlining factory automation by enhancing machine connectivity and production visibility. Lights-out manufacturing leverages cloud MES for autonomous operations with minimal human intervention, optimizing efficiency through predictive maintenance and adaptive control algorithms.

Factory Automation vs Lights-Out Manufacturing Infographic

industrydif.com

industrydif.com