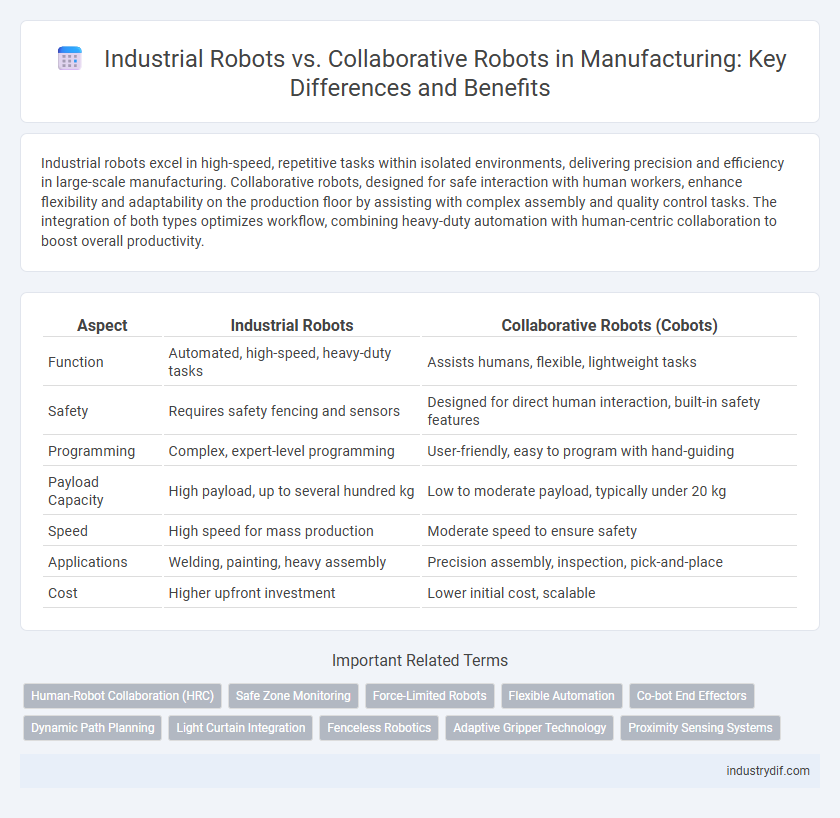

Industrial robots excel in high-speed, repetitive tasks within isolated environments, delivering precision and efficiency in large-scale manufacturing. Collaborative robots, designed for safe interaction with human workers, enhance flexibility and adaptability on the production floor by assisting with complex assembly and quality control tasks. The integration of both types optimizes workflow, combining heavy-duty automation with human-centric collaboration to boost overall productivity.

Table of Comparison

| Aspect | Industrial Robots | Collaborative Robots (Cobots) |

|---|---|---|

| Function | Automated, high-speed, heavy-duty tasks | Assists humans, flexible, lightweight tasks |

| Safety | Requires safety fencing and sensors | Designed for direct human interaction, built-in safety features |

| Programming | Complex, expert-level programming | User-friendly, easy to program with hand-guiding |

| Payload Capacity | High payload, up to several hundred kg | Low to moderate payload, typically under 20 kg |

| Speed | High speed for mass production | Moderate speed to ensure safety |

| Applications | Welding, painting, heavy assembly | Precision assembly, inspection, pick-and-place |

| Cost | Higher upfront investment | Lower initial cost, scalable |

Introduction to Industrial and Collaborative Robots

Industrial robots are automated, programmable machines designed for high-volume, repetitive tasks in manufacturing environments, often operating in safety-isolated zones due to their power and speed. Collaborative robots, or cobots, are engineered to work safely alongside human workers, featuring advanced sensors and AI for real-time interaction and adaptability in small-batch production. The integration of industrial and collaborative robots optimizes efficiency, flexibility, and safety across diverse manufacturing processes.

Key Differences Between Industrial and Collaborative Robots

Industrial robots operate in segregated areas, designed for high-speed, precise, and repetitive tasks with limited human interaction, while collaborative robots (cobots) work safely alongside human operators, emphasizing flexibility and ease of programming. Industrial robots often require safety cages due to their high power and speed, whereas cobots incorporate advanced sensors and force feedback to ensure safe collaboration. Key differences include payload capacity, speed, workspace integration, and the level of human-robot interaction, with industrial robots excelling in heavy-duty applications and cobots enhancing adaptive, small-batch manufacturing processes.

Core Applications in Manufacturing

Industrial robots excel in high-volume, repetitive tasks such as welding, painting, and assembly lines, offering precision and speed in harsh or hazardous environments. Collaborative robots (cobots) are designed for close human interaction, enhancing flexibility in tasks like quality inspection, machine tending, and small batch production. Integration of cobots optimizes ergonomic workflows and supports adaptive manufacturing processes, driving efficiency in mixed automation settings.

Safety Standards and Risk Management

Industrial robots operate within segregated safety zones featuring physical barriers and safety interlocks to prevent human contact, ensuring compliance with ISO 10218 standards. Collaborative robots, or cobots, incorporate advanced force-limiting technologies and sensors that allow safe human-robot interaction under ISO/TS 15066 guidelines. Risk management practices emphasize hazard identification and mitigation strategies tailored to each robot type, promoting workplace safety through rigorous safety assessments and continuous monitoring.

Flexibility and Adaptability in Production Lines

Industrial robots excel in high-speed, repetitive tasks with limited flexibility, ideal for mass production environments requiring precision and consistency. Collaborative robots (cobots) offer greater adaptability, easily reprogrammed and integrated for various tasks alongside human workers in dynamic production lines. Their flexibility enables rapid changeovers and customization, optimizing manufacturing efficiency and reducing downtime.

Cost Considerations and ROI

Industrial robots typically involve higher upfront costs due to complex integration and maintenance requirements, but they offer substantial long-term ROI through increased productivity in high-volume manufacturing. Collaborative robots (cobots) have lower initial investment and faster deployment, making them cost-effective for small to medium-sized enterprises with flexible production needs. Evaluating total cost of ownership, including training, downtime, and scalability, is essential to optimize ROI in selecting between industrial robots and cobots.

Integration with Existing Manufacturing Systems

Industrial robots require complex integration processes involving extensive programming and specialized safety systems to operate seamlessly within existing manufacturing environments. Collaborative robots (cobots) feature user-friendly interfaces and adaptive technologies that enable easier and faster integration with current systems, minimizing downtime and facilitating flexible deployment. Manufacturers adopting cobots benefit from enhanced interoperability with legacy equipment and improved scalability across production lines.

Workforce Impacts and Human-Robot Collaboration

Industrial robots typically operate in segregated environments, reducing direct human interaction and impacting workforce roles by automating repetitive, hazardous tasks, which can lead to job displacement in certain sectors. Collaborative robots (cobots) are designed to work alongside humans, enhancing workforce productivity and safety by performing assistive functions that complement human skills, fostering upskilling and job transformation rather than replacement. The integration of cobots promotes a synergistic human-robot collaboration model, improving efficiency and ergonomics while supporting workforce adaptability in modern manufacturing environments.

Future Trends in Robotics for Manufacturing

Industrial robots will continue to dominate high-precision, high-volume manufacturing tasks due to their speed and accuracy, while collaborative robots (cobots) will increasingly integrate into assembly lines for flexible, human-robot interaction. Advances in AI and machine learning enable both robot types to improve adaptability, predictive maintenance, and real-time decision-making, significantly boosting operational efficiency. Future trends emphasize seamless integration of cobots with Industrial Internet of Things (IIoT) systems and enhanced safety features, driving smarter, more connected manufacturing environments.

Choosing the Right Robot for Your Manufacturing Needs

Industrial robots deliver high-speed, high-precision automation ideal for large-scale manufacturing processes requiring heavy-duty tasks and repetitive actions. Collaborative robots (cobots) offer flexibility and safety, enabling direct human-robot interaction in smaller production lines or tasks requiring adaptability and ease of deployment. Selecting the right robot depends on production volume, task complexity, workspace constraints, and integration requirements, ensuring optimized efficiency and cost-effectiveness in manufacturing operations.

Related Important Terms

Human-Robot Collaboration (HRC)

Industrial robots excel in high-speed, repetitive tasks with minimal human interaction, enhancing precision and efficiency in manufacturing processes. Collaborative robots (cobots) prioritize Human-Robot Collaboration (HRC) by operating safely alongside workers, enabling flexible automation and improving productivity through shared tasks.

Safe Zone Monitoring

Industrial robots require extensive safe zone monitoring to prevent human entry into hazardous areas, using physical barriers and light curtains to ensure operator safety. Collaborative robots feature advanced sensors and force limiters that allow safe operation alongside humans by actively detecting and responding to proximity without traditional safety barriers.

Force-Limited Robots

Force-limited robots, a subset of collaborative robots, enhance manufacturing safety by automatically reducing power and speed upon contact to prevent injuries, contrasting with traditional industrial robots that prioritize speed and precision but require safety barriers. This technology enables seamless human-robot collaboration on assembly lines, improving efficiency while maintaining stringent safety standards.

Flexible Automation

Industrial robots excel in high-volume, repetitive manufacturing tasks due to their precision and speed, while collaborative robots (cobots) offer flexible automation by working safely alongside human operators and easily adapting to varied processes. Flexible automation with cobots enhances productivity in small-batch production and complex assembly tasks through quick reprogramming and intuitive interfaces.

Co-bot End Effectors

Industrial robots feature heavy-duty end effectors designed for high-precision, repetitive tasks in hazardous environments, maximizing efficiency in mass production. Collaborative robots utilize versatile, lightweight end effectors equipped with advanced sensors to safely interact with human operators, enhancing flexibility and adaptability in shared workspaces.

Dynamic Path Planning

Industrial robots rely on pre-programmed, fixed-path trajectories for repetitive tasks, offering high precision but limited flexibility in dynamic environments. Collaborative robots feature advanced dynamic path planning algorithms that enable real-time adjustments to their movements, enhancing adaptability and safety when working alongside human operators.

Light Curtain Integration

Industrial robots typically require extensive safety measures such as light curtain integration to prevent accidents in high-speed, heavy-duty tasks, ensuring strict separation between humans and machines. Collaborative robots integrate light curtains with advanced sensors and force feedback systems allowing safer, close-proximity interaction and flexible human-robot collaboration on the manufacturing floor.

Fenceless Robotics

Industrial robots excel in high-volume, repetitive tasks with extensive safety barriers, while collaborative robots (cobots) enable fenceless robotics, allowing direct human-robot interaction and flexible automation on the manufacturing floor. Fenceless robotics optimize space utilization and workflow efficiency by integrating advanced sensors and real-time monitoring systems to ensure safe operation without physical safety fences.

Adaptive Gripper Technology

Industrial robots equipped with adaptive gripper technology deliver high precision and strength for repetitive manufacturing tasks, while collaborative robots utilize the same technology to safely interact with human workers, offering flexibility and fine-tuned grip adjustments for handling delicate objects. Adaptive grippers in both robot types improve efficiency by enabling dynamic responses to varied shapes and materials, reducing downtime and increasing overall productivity on the manufacturing floor.

Proximity Sensing Systems

Industrial robots rely on fixed safety barriers and basic proximity sensing systems for collision avoidance, limiting their flexibility in dynamic manufacturing environments. Collaborative robots integrate advanced proximity sensing technologies such as LiDAR and capacitive sensors, enabling safe human-robot interaction and real-time adaptive responses within shared workspaces.

Industrial Robots vs Collaborative Robots Infographic

industrydif.com

industrydif.com