Kaizen emphasizes continuous, incremental improvements driven by employee involvement to enhance manufacturing efficiency and reduce waste. Industry 5.0 integrates human creativity with advanced automation and AI, fostering collaboration between workers and robots for personalized production. Both approaches aim to optimize manufacturing processes but differ in their focus on human-centric innovation versus technological integration.

Table of Comparison

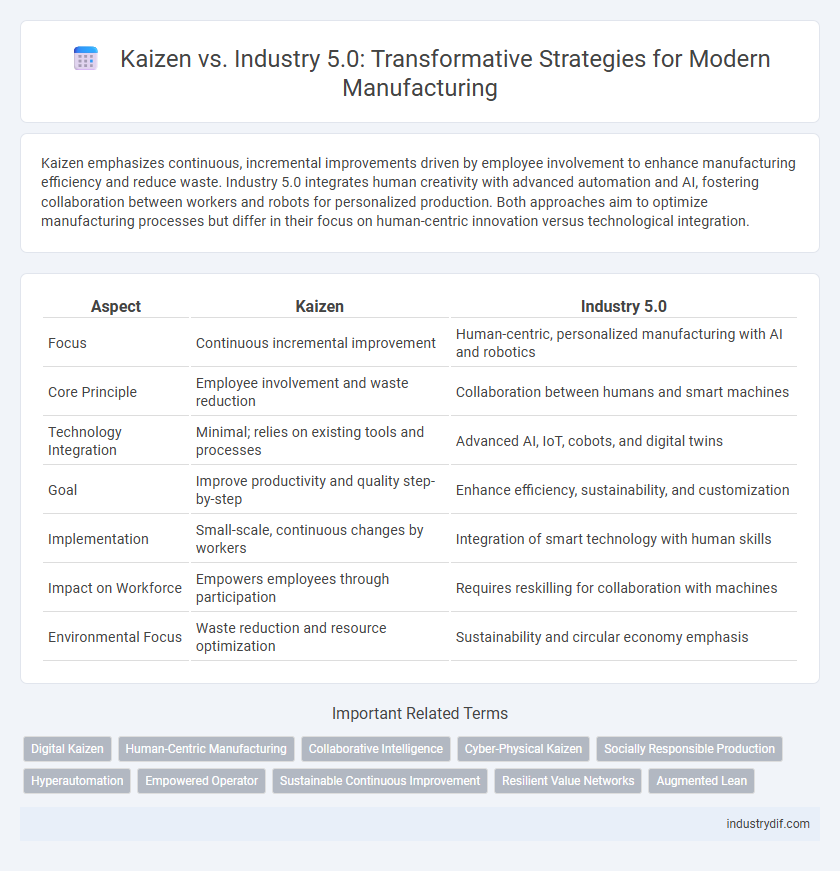

| Aspect | Kaizen | Industry 5.0 |

|---|---|---|

| Focus | Continuous incremental improvement | Human-centric, personalized manufacturing with AI and robotics |

| Core Principle | Employee involvement and waste reduction | Collaboration between humans and smart machines |

| Technology Integration | Minimal; relies on existing tools and processes | Advanced AI, IoT, cobots, and digital twins |

| Goal | Improve productivity and quality step-by-step | Enhance efficiency, sustainability, and customization |

| Implementation | Small-scale, continuous changes by workers | Integration of smart technology with human skills |

| Impact on Workforce | Empowers employees through participation | Requires reskilling for collaboration with machines |

| Environmental Focus | Waste reduction and resource optimization | Sustainability and circular economy emphasis |

Understanding Kaizen: The Foundation of Continuous Improvement

Kaizen, a Japanese philosophy centered on continuous, incremental improvements in manufacturing processes, emphasizes employee involvement and waste reduction to enhance productivity and quality. It fosters a culture where every worker contributes ideas for improvement, creating a sustainable environment for operational excellence. In contrast, Industry 5.0 integrates advanced technologies with human creativity, but Kaizen remains foundational for continuous improvement by embedding a mindset of persistent, small-scale enhancements.

Defining Industry 5.0: Human-Centric Smart Manufacturing

Industry 5.0 revolutionizes manufacturing by integrating human creativity with advanced technologies like AI, robotics, and IoT, emphasizing a human-centric approach to smart factories. Unlike Kaizen's continuous incremental improvement, Industry 5.0 focuses on collaboration between human workers and intelligent machines to enhance customization, flexibility, and sustainability. This paradigm shift aims to optimize not only productivity but also worker well-being and environmental impact, driving the next generation of manufacturing innovation.

Key Principles: Kaizen vs Industry 5.0

Kaizen emphasizes continuous, incremental improvements through employee involvement and standardized processes, fostering efficiency and waste reduction in manufacturing. Industry 5.0 integrates human creativity with advanced technologies like AI, robotics, and IoT to enable personalized production while promoting sustainability and resilience. Both frameworks prioritize enhancing productivity but diverge in scale and approach, with Kaizen focusing on small-scale, ongoing improvements and Industry 5.0 targeting collaborative, technology-driven innovation.

Evolution of Manufacturing: From Kaizen to Industry 5.0

Kaizen revolutionized manufacturing with continuous, incremental improvements focusing on efficiency and waste reduction, laying the foundation for lean production systems. Industry 5.0 advances this evolution by integrating human creativity and advanced technologies like AI, robotics, and IoT, emphasizing personalized products and sustainable practices. This shift promotes a collaborative environment where human workers and smart machines co-create value while enhancing flexibility and resilience in manufacturing processes.

Human Involvement: Workers’ Role in Both Approaches

Kaizen emphasizes continuous incremental improvements driven by frontline workers' active participation in identifying inefficiencies and suggesting solutions, fostering a culture of employee empowerment. Industry 5.0 integrates advanced technologies such as AI and robotics with human creativity and decision-making, positioning workers as collaborative partners to machines rather than mere operators. This shift enhances human-centric manufacturing by prioritizing skill development, personalized roles, and ergonomic work environments to complement automation.

Technology Integration: Automation in Kaizen and Industry 5.0

Kaizen emphasizes incremental process improvements through human-driven automation, focusing on worker involvement and continuous refinement of existing systems. Industry 5.0 integrates advanced technologies such as collaborative robots (cobots), artificial intelligence, and IoT to create smart factories that enhance human-machine collaboration. This shift enables real-time data analytics and adaptive automation, optimizing manufacturing efficiency while preserving human creativity and decision-making.

Efficiency and Productivity: Comparative Impact

Kaizen emphasizes continuous incremental improvements in manufacturing processes, resulting in steady gains in efficiency and productivity through employee involvement and waste reduction. Industry 5.0 integrates advanced technologies like artificial intelligence and human-robot collaboration, driving exponential productivity growth and personalized manufacturing while maintaining sustainability. The comparative impact reveals Kaizen's focus on gradual human-centric optimization, whereas Industry 5.0 delivers rapid, tech-enhanced efficiency breakthroughs tailored for future smart factories.

Sustainability in Manufacturing: Kaizen and Industry 5.0 Perspectives

Kaizen emphasizes continuous incremental improvements to enhance efficiency and reduce waste, thereby promoting sustainability through lean manufacturing principles. Industry 5.0 integrates human creativity with advanced technologies like AI and robotics to create more sustainable, personalized production processes that minimize environmental impact. Combining Kaizen's focus on process optimization with Industry 5.0's human-centric and technological innovations drives sustainable manufacturing by improving resource use and reducing carbon footprints.

Implementation Challenges: Barriers and Solutions

Implementing Kaizen in manufacturing often encounters resistance due to entrenched workplace cultures and limited employee engagement, while Industry 5.0 faces challenges integrating advanced technologies such as AI and collaborative robots with human operators. Overcoming these barriers requires targeted training programs, change management strategies, and robust digital infrastructure to facilitate seamless human-machine collaboration. Combining continuous improvement principles from Kaizen with Industry 5.0's human-centric automation optimizes productivity and innovation within production environments.

The Future of Manufacturing: Synergy between Kaizen and Industry 5.0

Kaizen's continuous improvement methodology enhances operational efficiency through incremental changes, fostering a culture of employee-driven innovation. Industry 5.0 integrates human creativity with advanced technologies such as AI, robotics, and IoT, emphasizing personalized and sustainable manufacturing processes. The future of manufacturing lies in synergizing Kaizen's human-centric incremental improvements with Industry 5.0's technological advancements to create adaptive, resilient, and highly efficient production ecosystems.

Related Important Terms

Digital Kaizen

Digital Kaizen integrates Industry 5.0 principles by leveraging advanced technologies such as AI, IoT, and robotics to continuously enhance manufacturing processes, boosting efficiency and customization. This fusion transforms traditional Kaizen's incremental improvements into dynamic, data-driven optimization aligned with human-centric smart production systems.

Human-Centric Manufacturing

Kaizen emphasizes continuous incremental improvements driven by employee involvement to enhance efficiency and reduce waste in manufacturing processes. Industry 5.0 centers on human-centric manufacturing by integrating advanced technologies like AI and robotics to empower workers, improve collaboration, and foster innovation while maintaining sustainability.

Collaborative Intelligence

Kaizen emphasizes continuous, incremental improvements driven by human insight and teamwork within manufacturing processes. Industry 5.0 advances this by integrating collaborative intelligence, combining human creativity with AI-driven technologies for enhanced precision, customization, and productivity.

Cyber-Physical Kaizen

Cyber-Physical Kaizen integrates real-time data from IoT devices and smart sensors to continuously optimize manufacturing processes, enhancing the traditional Kaizen philosophy through advanced Industry 5.0 technologies. This synergy enables adaptive, human-centric production systems that improve efficiency, reduce waste, and foster seamless collaboration between humans and machines.

Socially Responsible Production

Kaizen emphasizes continuous, incremental improvements driven by employee involvement to enhance socially responsible production practices in manufacturing. Industry 5.0 integrates advanced automation with human creativity, fostering sustainable and socially responsible manufacturing by prioritizing worker well-being and environmental impact.

Hyperautomation

Kaizen emphasizes continuous incremental improvements driven by employee involvement, while Industry 5.0 integrates human creativity with advanced hyperautomation technologies such as AI and robotics to enhance manufacturing efficiency and customization. Hyperautomation in Industry 5.0 leverages intelligent automation and real-time data analytics to optimize production processes beyond traditional Kaizen methodologies.

Empowered Operator

Kaizen emphasizes continuous incremental improvements driven by employee involvement, fostering a culture where empowered operators identify and solve problems on the manufacturing floor. Industry 5.0 advances this concept by integrating human creativity with advanced technologies like AI and cobots, further enhancing operator empowerment through collaborative automation and personalized work environments.

Sustainable Continuous Improvement

Kaizen emphasizes employee-driven, incremental improvements focused on waste reduction and efficiency, while Industry 5.0 integrates human creativity with advanced technologies such as AI and robotics to achieve sustainable continuous improvement. Combining Kaizen's principles with Industry 5.0's human-centric automation enhances environmentally friendly manufacturing processes, promoting resilience and long-term operational excellence.

Resilient Value Networks

Kaizen emphasizes continuous incremental improvements in manufacturing processes to enhance efficiency and reduce waste, fostering a resilient value network through employee-driven innovations. Industry 5.0 expands this by integrating advanced technologies like AI and IoT with human creativity, enabling adaptive, personalized, and sustainable value networks that respond dynamically to disruptions.

Augmented Lean

Kaizen's continuous incremental improvements emphasize waste reduction and employee empowerment, while Industry 5.0 integrates human-centric approaches with advanced technologies like AI and robotics to enhance production flexibility and customization. Augmented Lean combines Kaizen's principles with Industry 5.0 by leveraging real-time data analytics and augmented reality tools to optimize workflows, minimize downtime, and improve decision-making in smart manufacturing environments.

Kaizen vs Industry 5.0 Infographic

industrydif.com

industrydif.com