CNC machining offers precise and repeatable production of complex parts through subtractive manufacturing processes, ideal for high-volume runs and tight tolerances. Generative design leverages AI algorithms to create optimized, lightweight structures that maximize material efficiency and performance, often resulting in innovative geometries unattainable by traditional methods. Combining CNC machining with generative design can enhance manufacturing capabilities by producing sophisticated components that meet stringent design and functional requirements.

Table of Comparison

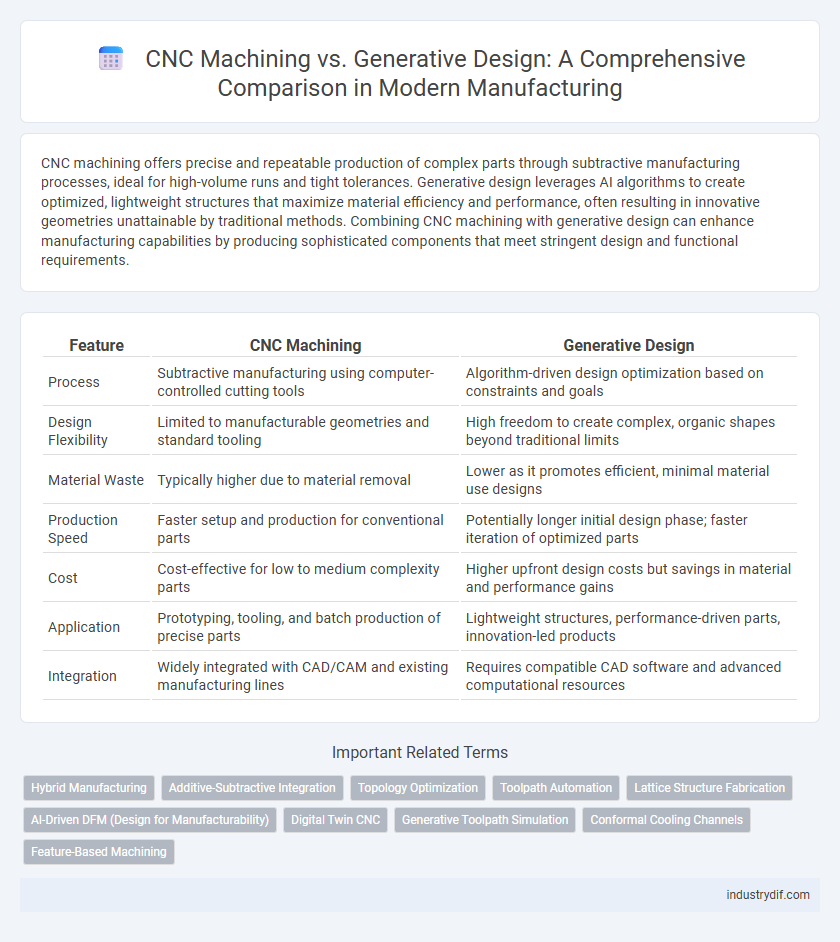

| Feature | CNC Machining | Generative Design |

|---|---|---|

| Process | Subtractive manufacturing using computer-controlled cutting tools | Algorithm-driven design optimization based on constraints and goals |

| Design Flexibility | Limited to manufacturable geometries and standard tooling | High freedom to create complex, organic shapes beyond traditional limits |

| Material Waste | Typically higher due to material removal | Lower as it promotes efficient, minimal material use designs |

| Production Speed | Faster setup and production for conventional parts | Potentially longer initial design phase; faster iteration of optimized parts |

| Cost | Cost-effective for low to medium complexity parts | Higher upfront design costs but savings in material and performance gains |

| Application | Prototyping, tooling, and batch production of precise parts | Lightweight structures, performance-driven parts, innovation-led products |

| Integration | Widely integrated with CAD/CAM and existing manufacturing lines | Requires compatible CAD software and advanced computational resources |

Introduction to CNC Machining and Generative Design

CNC machining utilizes computer-controlled tools to precisely cut and shape materials based on digital design files, ensuring high accuracy and repeatability in manufacturing processes. Generative design leverages algorithmic software to explore numerous design alternatives by inputting specific constraints and goals, optimizing for factors like weight, strength, and material efficiency. Both technologies enhance product development by combining precision machining with innovative, performance-driven design solutions.

Defining CNC Machining: Processes and Applications

CNC machining utilizes computer-controlled tools to remove material from a workpiece, enabling the precise creation of complex parts across metals, plastics, and composites. It is extensively applied in industries such as aerospace, automotive, medical devices, and electronics for prototyping and production. The process includes milling, turning, drilling, and grinding, ensuring high repeatability and tight tolerances for functional and structural components.

What is Generative Design? Key Principles and Benefits

Generative design is an advanced manufacturing process that uses algorithms and artificial intelligence to create optimized product designs based on specified parameters and constraints. Key principles include iterative exploration of multiple design solutions, material efficiency, and performance-driven innovation, enabling manufacturers to achieve lightweight, cost-effective, and structurally robust components. Benefits of generative design encompass reduced development time, enhanced product functionality, and minimized waste compared to traditional CNC machining, making it a transformative approach in modern manufacturing.

Comparing CNC Machining and Generative Design: Core Differences

CNC machining involves subtractive manufacturing by precisely cutting material from a solid block, ensuring high accuracy and repeatability for complex parts. Generative design leverages advanced algorithms and AI to create optimized geometries that balance material use and performance, often producing innovative, lightweight structures unattainable by traditional methods. While CNC machining excels in precision and finish quality, generative design prioritizes design innovation and resource efficiency, transforming the initial concept phase in manufacturing workflows.

Material Considerations in CNC Machining vs Generative Design

CNC machining offers precise control over a wide range of materials, including metals, plastics, and composites, making it ideal for applications requiring specific mechanical and thermal properties. Generative design optimizes material usage by creating lightweight structures with complex geometries that traditional CNC machining cannot easily produce, often leveraging advanced materials like titanium alloys or high-performance polymers. Material considerations in CNC machining focus on machinability and tool wear, whereas generative design prioritizes material efficiency and structural performance tailored through computational algorithms.

Production Efficiency: Speed, Cost, and Scalability

CNC machining offers high speed and precision for low to medium volume production with predictable costs, making it efficient for standardized parts. Generative design enhances production scalability by optimizing complex geometries that reduce material usage and assembly time, lowering overall costs in large-scale manufacturing. Combining CNC machining with generative design algorithms accelerates prototyping cycles and enables cost-effective scalability for diverse production needs.

Design Flexibility and Limitations

CNC machining offers precise control and repeatability but is limited by tool accessibility and geometric constraints, making complex internal features challenging to produce. Generative design leverages AI algorithms to explore vast design iterations, resulting in lightweight, optimized structures that are often impossible to create with traditional subtractive methods. The combination of generative design with advanced CNC machining maximizes design flexibility while addressing manufacturing limitations.

Integration with Digital Manufacturing Systems

CNC machining offers precise control and repeatability through direct integration with established digital manufacturing systems like CAD/CAM software, enabling seamless toolpath generation and machine operation. Generative design complements these systems by utilizing AI-driven algorithms to optimize part geometry and material usage before CNC execution, enhancing efficiency and performance. Combining both approaches within digital manufacturing ecosystems accelerates production workflows and fosters innovative product development.

Industry Use Cases: When to Choose CNC Machining or Generative Design

CNC machining excels in producing precise, durable parts with tight tolerances, ideal for low to medium volume manufacturing in aerospace, automotive, and medical device industries. Generative design is suited for creating lightweight, complex geometries often used in aerospace and automotive sectors to optimize material usage and performance. Choosing between CNC machining and generative design depends on factors like production volume, design complexity, and specific mechanical requirements.

Future Trends: The Evolving Relationship Between CNC Machining and Generative Design

CNC machining remains essential for precision manufacturing, while generative design accelerates innovation by producing optimized, complex geometries unattainable through traditional methods. Future trends indicate a synergistic relationship where generative design algorithms create prototypes and components that CNC machines then fabricate with exceptional accuracy. The integration of AI-driven design and advanced CNC machining will redefine production efficiency and customization in the manufacturing industry.

Related Important Terms

Hybrid Manufacturing

Hybrid manufacturing integrates CNC machining's high-precision subtractive processes with generative design's advanced additive capabilities, optimizing component complexity and production efficiency. This combination enables manufacturers to achieve superior material utilization, reduced lead times, and enhanced performance in custom and low-volume parts production.

Additive-Subtractive Integration

Additive-subtractive integration enhances manufacturing efficiency by combining CNC machining's precision and generative design's optimized geometries to reduce material waste and production time. This hybrid approach leverages additive layering for complex shapes and subtractive milling for fine details, enabling scalable, cost-effective fabrication of high-performance components.

Topology Optimization

CNC machining excels in precision material removal based on fixed tool paths, while topology optimization within generative design leverages algorithm-driven material distribution to create lightweight, structurally efficient parts. Integrating topology optimization enhances CNC manufacturing by reducing material waste and improving mechanical performance through optimized geometries tailored to specific load conditions.

Toolpath Automation

CNC machining leverages precise toolpath automation to execute complex cuts based on predefined programming, ensuring consistent manufacturing accuracy and reduced human error. Generative design enhances this process by algorithmically creating optimized toolpaths that minimize material waste and machining time, driving efficiency and innovation in production workflows.

Lattice Structure Fabrication

CNC machining excels in producing precise lattice structures through subtractive manufacturing, enabling high accuracy in metal and plastic components with complex geometries. Generative design enhances lattice structure fabrication by utilizing AI-driven algorithms to optimize weight, strength, and material usage, often producing designs that CNC machines then refine for manufacturability.

AI-Driven DFM (Design for Manufacturability)

AI-driven DFM integrates CNC machining precision with generative design algorithms to optimize manufacturing workflows, reducing material waste and production time. This synergy enables real-time adjustments and predictive analytics, enhancing component quality while lowering costs in high-complexity manufacturing environments.

Digital Twin CNC

Digital Twin CNC integrates real-time data from CNC machining processes with generative design algorithms, enabling precise simulation and optimization of manufacturing parameters to enhance product quality and reduce production time. This synergy allows manufacturers to predict tool wear, optimize machine performance, and iterate designs virtually, significantly improving efficiency and cost-effectiveness in digital manufacturing workflows.

Generative Toolpath Simulation

Generative toolpath simulation leverages AI-driven algorithms to optimize CNC machining processes by automatically generating efficient and collision-free machining paths, significantly reducing production time and material waste. This advanced simulation technology enhances precision and adaptability compared to traditional CNC programming by dynamically adjusting toolpaths based on real-time feedback and complex geometries.

Conformal Cooling Channels

CNC machining enables precise fabrication of conformal cooling channels with tight tolerances, optimizing heat dissipation in injection molds; generative design, leveraging AI algorithms, creates complex channel geometries that follow part contours more closely for enhanced thermal management and reduced cycle times. Integrating generative design with additive manufacturing further improves mold performance by enabling intricate conformal cooling paths unachievable through traditional CNC machining alone.

Feature-Based Machining

Feature-based machining in CNC machining enables precise control over manufacturing processes by identifying and exploiting specific geometric features on a workpiece, enhancing efficiency and reducing cycle times. Generative design integrates with feature-based machining by automatically creating optimized part geometries that align with machinable features, streamlining production while maximizing material usage and structural performance.

CNC Machining vs Generative Design Infographic

industrydif.com

industrydif.com