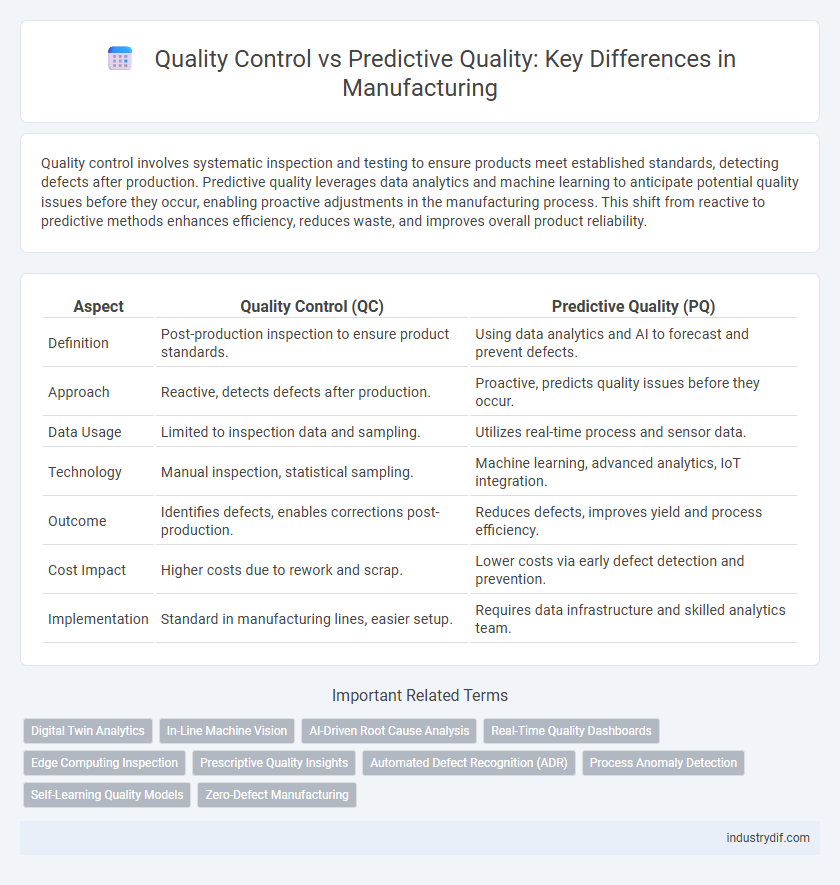

Quality control involves systematic inspection and testing to ensure products meet established standards, detecting defects after production. Predictive quality leverages data analytics and machine learning to anticipate potential quality issues before they occur, enabling proactive adjustments in the manufacturing process. This shift from reactive to predictive methods enhances efficiency, reduces waste, and improves overall product reliability.

Table of Comparison

| Aspect | Quality Control (QC) | Predictive Quality (PQ) |

|---|---|---|

| Definition | Post-production inspection to ensure product standards. | Using data analytics and AI to forecast and prevent defects. |

| Approach | Reactive, detects defects after production. | Proactive, predicts quality issues before they occur. |

| Data Usage | Limited to inspection data and sampling. | Utilizes real-time process and sensor data. |

| Technology | Manual inspection, statistical sampling. | Machine learning, advanced analytics, IoT integration. |

| Outcome | Identifies defects, enables corrections post-production. | Reduces defects, improves yield and process efficiency. |

| Cost Impact | Higher costs due to rework and scrap. | Lower costs via early defect detection and prevention. |

| Implementation | Standard in manufacturing lines, easier setup. | Requires data infrastructure and skilled analytics team. |

Introduction to Quality Control and Predictive Quality

Quality Control in manufacturing involves systematic inspection and testing of products to ensure they meet specified standards, reducing defects through reactive measures. Predictive Quality leverages data analytics and machine learning to forecast potential quality issues before they occur, enabling proactive adjustments in the production process. Integrating Predictive Quality with traditional Quality Control enhances efficiency by minimizing downtime and improving product consistency through actionable insights.

Definitions: Quality Control vs Predictive Quality

Quality Control involves the systematic inspection and testing of products to ensure they meet specified standards and detect defects after production. Predictive Quality uses advanced data analytics, machine learning, and sensor data to forecast potential quality issues before they occur, enabling proactive interventions. While Quality Control focuses on identifying problems post-manufacture, Predictive Quality aims to prevent defects by predicting quality deviations in real time.

Historical Evolution in Manufacturing Quality Approaches

Quality control in manufacturing traditionally relied on manual inspections and statistical process control to detect defects after production, focusing on maintaining consistency and adherence to specifications. Predictive quality integrates advanced data analytics, machine learning, and IoT sensors to forecast potential defects and process deviations before they occur, enabling proactive interventions. This shift from reactive quality control to predictive quality represents a significant evolution driven by technological advancements and the demand for higher efficiency and reduced waste in manufacturing processes.

Key Processes in Traditional Quality Control

Traditional quality control in manufacturing primarily involves inspection, measurement, and testing of finished products to ensure compliance with specified standards. Key processes include statistical process control (SPC), defect detection through visual or automated inspection, and sampling methods to identify non-conforming items. These methods rely heavily on historical data and reactive measures to maintain product quality.

Technologies Driving Predictive Quality

Advanced technologies such as machine learning algorithms, IoT sensors, and real-time data analytics are revolutionizing predictive quality in manufacturing by enabling early detection of defects and process deviations. Predictive quality leverages historical production data and continuous monitoring to forecast potential failures, reducing downtime and improving product consistency. This shift from traditional quality control to predictive quality optimizes resource allocation and enhances decision-making, driving efficiency and innovation in manufacturing processes.

Data Collection and Analysis in Quality Assurance

Quality Control relies on inspecting finished products and collecting manual inspection data to identify defects, ensuring compliance with predefined standards. Predictive Quality uses advanced data collection methods like IoT sensors and real-time analytics to monitor manufacturing processes, enabling early detection of potential quality issues. Machine learning algorithms analyze historical and real-time data to predict defects, optimize production parameters, and reduce waste in quality assurance.

Benefits and Limitations: Quality Control vs Predictive Quality

Quality Control in manufacturing ensures product compliance by detecting defects through inspection and testing, providing immediate feedback but often after production, leading to potential waste and rework. Predictive Quality uses data analytics and machine learning to forecast defects and process deviations before they occur, enhancing efficiency and reducing downtime but requiring substantial data infrastructure and expertise. While Quality Control offers reliability in standards enforcement, Predictive Quality drives proactive improvements but depends heavily on accurate data models and real-time monitoring capabilities.

Real-World Applications in Manufacturing

Quality Control in manufacturing relies on inspecting finished products to identify defects and maintain standards, often using statistical sampling and visual inspections. Predictive Quality leverages advanced technologies like machine learning, IoT sensors, and real-time data analytics to anticipate defects before they occur, enabling proactive adjustments in production processes. Real-world applications include automotive assembly lines where predictive maintenance and quality prediction models reduce downtime and scrap rates, while semiconductor manufacturing uses sensor data to optimize yield and ensure consistent product reliability.

Implementation Challenges and Considerations

Implementing quality control in manufacturing often involves manual inspections and reactive measures that can delay defect detection, while predictive quality leverages machine learning and IoT sensors to anticipate issues in real-time, posing challenges in data integration and model accuracy. Ensuring data quality, managing high volumes of sensor inputs, and aligning predictive algorithms with existing workflows are critical considerations for successful adoption. Workforce training and change management play essential roles in overcoming resistance and maximizing the benefits of predictive quality systems.

Future Trends in Manufacturing Quality Management

Predictive Quality leverages AI and IoT sensors to analyze real-time manufacturing data, enabling proactive defect prevention and reducing scrap rates. Future trends emphasize integrating machine learning models with automated quality control systems to enhance process optimization and maintain consistent product standards. Advancements in digital twins and edge computing further empower manufacturers to predict quality issues before production, driving higher efficiency and cost savings.

Related Important Terms

Digital Twin Analytics

Quality Control relies on traditional inspection methods and statistical process control to identify defects, whereas Predictive Quality leverages Digital Twin Analytics to simulate real-time production scenarios, enabling proactive detection and prevention of quality issues. By integrating sensor data and machine learning algorithms, Digital Twins provide dynamic insights into product performance and process variations, driving continuous improvement and reducing manufacturing downtime.

In-Line Machine Vision

In-line machine vision in manufacturing enables real-time quality control by detecting defects during production, reducing waste and rework. Predictive quality leverages this data with AI algorithms to forecast potential failures, optimizing process parameters before defects occur.

AI-Driven Root Cause Analysis

AI-driven root cause analysis enhances predictive quality by automatically identifying patterns and anomalies in manufacturing data, reducing downtime and improving defect detection rates. Traditional quality control relies on historical inspections, whereas predictive quality employs machine learning algorithms to anticipate defects before they occur, increasing overall production efficiency.

Real-Time Quality Dashboards

Real-time quality dashboards integrate predictive quality analytics with traditional quality control metrics, enabling manufacturers to identify defects and process deviations instantly, reducing downtime and improving product consistency. These dashboards leverage machine learning algorithms and IoT sensor data to provide actionable insights, facilitating proactive decision-making and minimizing the risk of quality issues before they escalate.

Edge Computing Inspection

Edge computing inspection enables real-time data analysis directly on the manufacturing floor, improving the accuracy and speed of quality control processes. Predictive quality leverages machine learning models deployed at the edge to identify potential defects before they occur, reducing downtime and enhancing overall production efficiency.

Prescriptive Quality Insights

Prescriptive quality insights leverage advanced analytics and machine learning to recommend specific corrective actions, enhancing traditional quality control's reactive approach by preventing defects before they occur. Integrating real-time data from manufacturing processes enables prescriptive models to optimize production parameters, reduce waste, and improve product consistency.

Automated Defect Recognition (ADR)

Automated Defect Recognition (ADR) enhances traditional Quality Control by utilizing machine learning algorithms and real-time data analysis to identify defects with higher accuracy and speed, reducing human error and operational costs. Predictive Quality leverages ADR-generated data to forecast potential defects before they occur, enabling proactive adjustments in the manufacturing process and improving overall product reliability.

Process Anomaly Detection

Quality Control relies on post-production inspections to identify defects, while Predictive Quality employs real-time Process Anomaly Detection using machine learning algorithms to detect deviations before they impact product standards. Implementing advanced sensors and AI-driven analytics enhances early anomaly identification, reducing downtime and improving overall manufacturing efficiency.

Self-Learning Quality Models

Self-learning quality models enhance manufacturing by continuously analyzing real-time production data to predict defects before they occur, outperforming traditional quality control methods that rely on post-production inspection. Leveraging machine learning algorithms, these models adapt to changing process conditions, reducing errors and improving overall product reliability.

Zero-Defect Manufacturing

Quality control relies on post-production inspection to identify defects, whereas predictive quality leverages real-time data analytics and machine learning to anticipate and prevent defects, driving Zero-Defect Manufacturing. Implementing predictive quality systems enhances process reliability and reduces waste, achieving near-perfect production efficiency.

Quality Control vs Predictive Quality Infographic

industrydif.com

industrydif.com