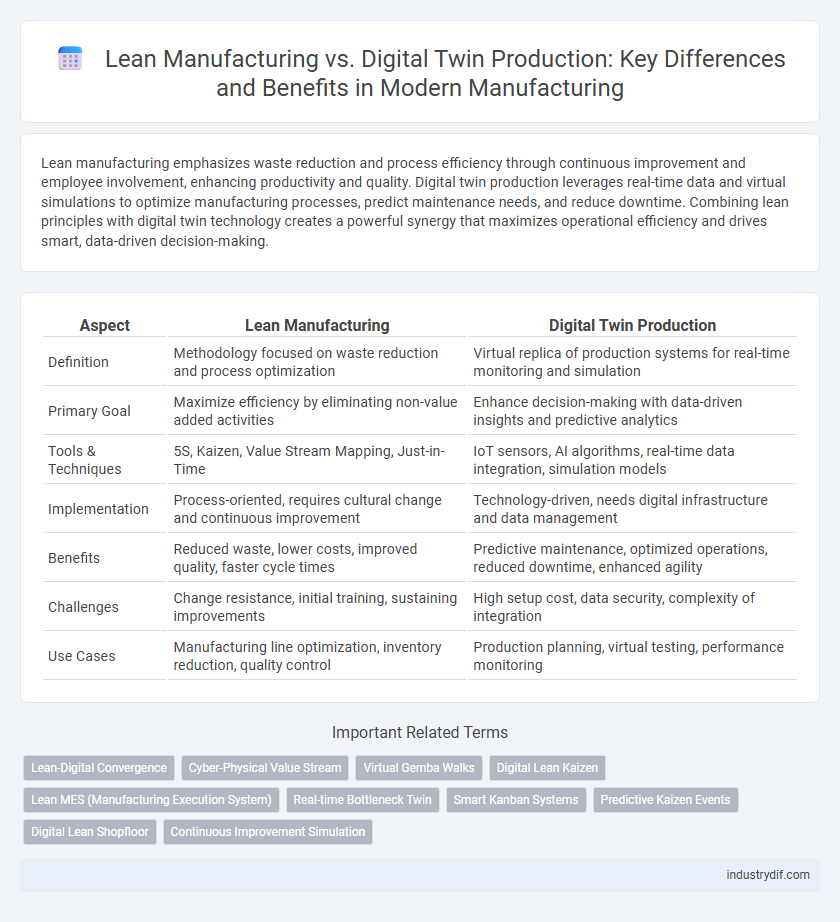

Lean manufacturing emphasizes waste reduction and process efficiency through continuous improvement and employee involvement, enhancing productivity and quality. Digital twin production leverages real-time data and virtual simulations to optimize manufacturing processes, predict maintenance needs, and reduce downtime. Combining lean principles with digital twin technology creates a powerful synergy that maximizes operational efficiency and drives smart, data-driven decision-making.

Table of Comparison

| Aspect | Lean Manufacturing | Digital Twin Production |

|---|---|---|

| Definition | Methodology focused on waste reduction and process optimization | Virtual replica of production systems for real-time monitoring and simulation |

| Primary Goal | Maximize efficiency by eliminating non-value added activities | Enhance decision-making with data-driven insights and predictive analytics |

| Tools & Techniques | 5S, Kaizen, Value Stream Mapping, Just-in-Time | IoT sensors, AI algorithms, real-time data integration, simulation models |

| Implementation | Process-oriented, requires cultural change and continuous improvement | Technology-driven, needs digital infrastructure and data management |

| Benefits | Reduced waste, lower costs, improved quality, faster cycle times | Predictive maintenance, optimized operations, reduced downtime, enhanced agility |

| Challenges | Change resistance, initial training, sustaining improvements | High setup cost, data security, complexity of integration |

| Use Cases | Manufacturing line optimization, inventory reduction, quality control | Production planning, virtual testing, performance monitoring |

Introduction to Lean Manufacturing and Digital Twin Production

Lean Manufacturing emphasizes waste reduction and continuous improvement through techniques like value stream mapping and just-in-time production, enhancing efficiency and product quality. Digital Twin Production leverages real-time digital replicas of physical assets to simulate, predict, and optimize manufacturing processes, enabling proactive decision-making and minimizing downtime. Combining Lean principles with Digital Twin technology drives operational excellence by integrating process optimization with advanced data analytics.

Key Principles of Lean Manufacturing

Lean Manufacturing centers on eliminating waste, optimizing workflows, and enhancing product quality through continuous improvement and just-in-time production. Key principles include value stream mapping to identify inefficiencies, pull systems to reduce inventory, and empowering employees for problem-solving. Implementing standardized processes and minimizing non-value-added activities ensures a streamlined, cost-efficient manufacturing environment.

Defining Digital Twin Production in Modern Industry

Digital Twin Production in modern manufacturing refers to the creation of a precise virtual replica of physical production processes, enabling real-time monitoring, simulation, and optimization. This technology integrates IoT sensors, AI analytics, and digital modeling to enhance predictive maintenance, reduce downtime, and improve quality control. By providing actionable insights through continuous data feedback, Digital Twin Production drives efficiency and innovation beyond traditional Lean Manufacturing practices.

Core Differences Between Lean and Digital Twin Approaches

Lean Manufacturing emphasizes waste reduction, continuous improvement, and value stream optimization through methods such as Kaizen and Just-In-Time inventory. Digital Twin Production leverages real-time data, virtual replicas, and simulation models to enhance predictive maintenance and process optimization. The core difference lies in Lean's process-driven efficiency versus Digital Twin's technology-driven insight and dynamic system replication.

Benefits of Lean Manufacturing for Operational Efficiency

Lean Manufacturing enhances operational efficiency by minimizing waste and optimizing resource utilization, resulting in lower production costs and faster cycle times. Streamlined workflows and continuous improvement practices improve product quality and reduce defects, leading to higher customer satisfaction. Real-time problem identification and elimination foster a culture of efficiency and employee engagement, driving sustained productivity gains.

Advantages of Digital Twin Production in Manufacturing

Digital Twin Production in manufacturing offers real-time monitoring and predictive analytics, enabling proactive maintenance and reducing downtime. It enhances process optimization through virtual simulations, leading to higher efficiency and cost savings compared to traditional Lean Manufacturing. Integration with IoT devices allows precise control over production variables, improving product quality and accelerating time-to-market.

Integration of Lean Practices with Digital Twin Technology

Integrating Lean Manufacturing principles with Digital Twin technology enhances production efficiency by providing real-time data visualization and process simulation, enabling precise identification and elimination of waste. This convergence facilitates continuous improvement through predictive analytics, allowing manufacturers to optimize workflows and reduce downtime. Combining Lean's focus on value stream mapping with the Digital Twin's dynamic modeling accelerates decision-making and drives sustainable operational excellence.

Challenges in Adopting Lean vs Digital Twin Production

Lean manufacturing faces challenges such as resistance to cultural change, difficulty in sustaining continuous improvement, and limitations in real-time data accuracy. Digital twin production encounters obstacles including high initial investment costs, complexity in integrating with existing systems, and reliance on advanced data analytics capabilities. Both approaches demand significant shifts in workforce skills and organizational mindset to achieve successful adoption.

Impact on Quality, Cost, and Lead Time

Lean Manufacturing reduces waste and enhances process efficiency, significantly lowering production costs and lead times while improving product quality through continuous improvement techniques. Digital Twin Production enables real-time simulation and predictive analytics, providing precise quality control, reducing defects, and optimizing resource allocation to minimize costs and accelerate lead times. Combining Lean principles with Digital Twin technology drives superior operational performance by integrating data-driven decision-making with streamlined workflows.

Future Trends: Synergizing Lean Manufacturing and Digital Twins

Future trends in manufacturing highlight the integration of Lean Manufacturing principles with Digital Twin technology to enhance operational efficiency and reduce waste. Leveraging real-time data simulation from Digital Twins enables continuous process improvement, aligning perfectly with Lean's emphasis on value maximization and defect minimization. This synergy drives smarter decision-making and predictive maintenance, revolutionizing production lines with increased agility and sustainability.

Related Important Terms

Lean-Digital Convergence

Lean manufacturing's emphasis on waste reduction and continuous improvement converges with digital twin production's real-time simulation and predictive analytics, enhancing operational efficiency and product quality. The integration of IoT sensors with lean principles enables dynamic process optimization, driving smarter decision-making and accelerated innovation cycles in manufacturing environments.

Cyber-Physical Value Stream

Lean Manufacturing enhances efficiency by minimizing waste and optimizing workflows, while Digital Twin Production leverages real-time data to simulate and improve manufacturing processes; integrating both within a Cyber-Physical Value Stream creates a synchronized digital-physical feedback loop, driving continuous operational improvements and reducing production downtime. This synergy enables precise monitoring, predictive maintenance, and agile decision-making, resulting in higher product quality and accelerated time-to-market.

Virtual Gemba Walks

Lean Manufacturing emphasizes continuous improvement and waste reduction through direct observation on the shop floor, while Digital Twin Production leverages virtual replicas of physical operations to enable Virtual Gemba Walks, enhancing remote monitoring and data-driven decision-making. Virtual Gemba Walks utilize real-time data and simulation to identify process inefficiencies and optimize production workflows without interrupting actual manufacturing activities.

Digital Lean Kaizen

Digital Lean Kaizen integrates Lean Manufacturing principles with real-time data from Digital Twin Production models, enabling continuous process improvement through precise simulation and analysis. This synergy accelerates waste reduction and productivity enhancement by providing actionable insights for rapid, iterative refinement in manufacturing operations.

Lean MES (Manufacturing Execution System)

Lean Manufacturing emphasizes waste reduction and process efficiency through continuous improvement, while Digital Twin Production leverages real-time data and simulation for proactive decision-making. Lean MES integrates these methodologies by providing streamlined digital workflows and real-time analytics to optimize production, reduce lead times, and enhance resource utilization.

Real-time Bottleneck Twin

Lean Manufacturing minimizes waste and streamlines workflows by identifying bottlenecks through continuous value stream mapping and just-in-time production. Digital Twin Production enhances this approach by creating a real-time Bottleneck Twin that simulates and monitors production constraints, enabling predictive adjustments and dynamic resource allocation to optimize throughput and reduce downtime.

Smart Kanban Systems

Smart Kanban Systems enhance Lean Manufacturing by integrating real-time data analytics and IoT sensors to optimize inventory flow and reduce waste, while Digital Twin Production utilizes virtual replicas of physical assets to simulate, predict, and improve manufacturing processes. Combining these technologies accelerates decision-making, minimizes downtime, and increases operational efficiency through continuous monitoring and adaptive scheduling.

Predictive Kaizen Events

Lean Manufacturing emphasizes continuous improvement through standardized processes and waste reduction, while Digital Twin Production enhances Predictive Kaizen Events by using real-time data simulations to identify inefficiencies before they occur. Implementing Digital Twin technology allows manufacturers to proactively target process variances, accelerating Kaizen initiatives and maximizing operational efficiency.

Digital Lean Shopfloor

Digital Lean Shopfloor integrates Lean Manufacturing principles with Digital Twin technology to optimize production efficiency and minimize waste by providing real-time, data-driven insights into factory operations. This advanced approach enables precise simulation and continuous improvement of workflows, accelerating decision-making and enhancing overall equipment effectiveness (OEE).

Continuous Improvement Simulation

Lean Manufacturing emphasizes waste reduction and process efficiency through iterative continuous improvement cycles, while Digital Twin Production enhances this by simulating real-time production scenarios for proactive adjustments. Continuous Improvement Simulation in Digital Twin environments enables precise prediction and optimization of manufacturing workflows, leading to accelerated problem-solving and reduced downtime.

Lean Manufacturing vs Digital Twin Production Infographic

industrydif.com

industrydif.com