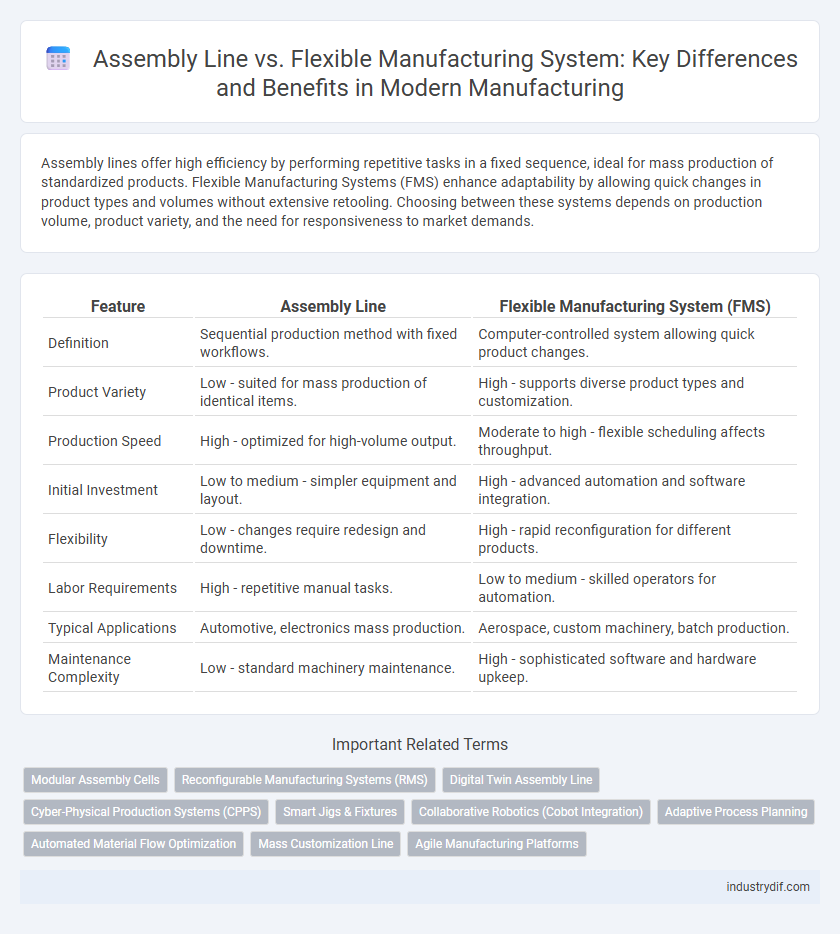

Assembly lines offer high efficiency by performing repetitive tasks in a fixed sequence, ideal for mass production of standardized products. Flexible Manufacturing Systems (FMS) enhance adaptability by allowing quick changes in product types and volumes without extensive retooling. Choosing between these systems depends on production volume, product variety, and the need for responsiveness to market demands.

Table of Comparison

| Feature | Assembly Line | Flexible Manufacturing System (FMS) |

|---|---|---|

| Definition | Sequential production method with fixed workflows. | Computer-controlled system allowing quick product changes. |

| Product Variety | Low - suited for mass production of identical items. | High - supports diverse product types and customization. |

| Production Speed | High - optimized for high-volume output. | Moderate to high - flexible scheduling affects throughput. |

| Initial Investment | Low to medium - simpler equipment and layout. | High - advanced automation and software integration. |

| Flexibility | Low - changes require redesign and downtime. | High - rapid reconfiguration for different products. |

| Labor Requirements | High - repetitive manual tasks. | Low to medium - skilled operators for automation. |

| Typical Applications | Automotive, electronics mass production. | Aerospace, custom machinery, batch production. |

| Maintenance Complexity | Low - standard machinery maintenance. | High - sophisticated software and hardware upkeep. |

Introduction to Assembly Line and Flexible Manufacturing System

Assembly lines streamline production by organizing workstations in a linear sequence, enabling high-volume manufacturing of standardized products with minimal labor variations. Flexible Manufacturing Systems (FMS) integrate computer-controlled machines and automated material handling to adapt quickly to product changes and varying production volumes. Both approaches enhance efficiency, but FMS offers greater adaptability for customized manufacturing needs.

Key Differences Between Assembly Line and Flexible Manufacturing System

Assembly lines focus on high-volume production of standardized products through sequential, fixed tasks, optimizing efficiency and minimizing cost per unit. Flexible Manufacturing Systems (FMS) incorporate automated machines and robots capable of producing diverse products with quick changeovers, emphasizing adaptability and responsiveness to market demands. The key differences lie in assembly line rigidity versus FMS versatility, production volume versus customization, and the degree of automation and integration in process workflows.

Advantages of Assembly Line Manufacturing

Assembly Line Manufacturing offers significant advantages such as high production efficiency and consistent product quality due to its standardized processes and repetitive tasks. This method reduces labor costs and minimizes production time by enabling workers to specialize in specific, streamlined operations. It is particularly effective for mass production of identical products, ensuring economies of scale and predictable output rates.

Benefits of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) enhance production efficiency by allowing rapid adjustments to product types and volumes without significant downtime. FMS reduces labor costs through automation while improving product quality via consistent precision and real-time error detection. The adaptability of FMS supports just-in-time manufacturing, minimizing inventory levels and responding swiftly to market demand fluctuations.

Efficiency Comparison: Assembly Line vs Flexible Manufacturing

Assembly lines maximize efficiency through high-speed, repetitive tasks optimized for mass production, resulting in lower per-unit costs and consistent quality. Flexible manufacturing systems (FMS) excel in adaptability, allowing quick changeovers and customization without significant downtime, enhancing responsiveness to market fluctuations. While assembly lines thrive in volume efficiency, FMS delivers superior efficiency in mixed-product environments by reducing setup times and increasing operational versatility.

Cost Implications in Both Manufacturing Systems

Assembly lines typically involve lower initial capital costs due to standardized equipment but incur higher costs related to inflexibility and changeover times, reducing efficiency with product variations. Flexible Manufacturing Systems (FMS) require significant upfront investment in advanced robotics and software integration but offer cost savings through reduced labor, minimized downtime, and rapid adaptation to different product designs. Manufacturers must evaluate the trade-off between the predictable, lower direct costs of assembly lines and the long-term economic benefits of FMS's adaptability and scalability.

Product Customization Capabilities

Assembly lines offer efficient mass production with limited product customization, as they rely on fixed sequences and specialized machinery designed for uniform output. Flexible Manufacturing Systems (FMS) enable high levels of product customization by integrating computer-controlled machines and automated material handling, allowing quick adjustments to production processes. FMS supports varied product types and small batch sizes, enhancing responsiveness to changing customer demands in manufacturing environments.

Scalability and Adaptability in Modern Manufacturing

Assembly lines offer high scalability for mass production with consistent output but lack adaptability to product variations, making them ideal for standardized goods. Flexible manufacturing systems (FMS) provide superior adaptability by enabling quick changeovers and customization without significant downtime, supporting small to medium batch production. Modern manufacturing increasingly favors FMS for its ability to scale efficiently while accommodating evolving market demands and product diversity.

Industry Applications and Use Cases

Assembly lines are predominantly used in high-volume, repetitive manufacturing industries such as automotive and consumer electronics due to their efficiency in producing standardized products. Flexible manufacturing systems (FMS) excel in industries requiring customization and small batch production, including aerospace and specialized machinery, by enabling rapid changeovers and adaptability. Integration of robotics and computer-controlled machining in FMS supports diverse product variants, optimizing production for complex and evolving market demands.

Future Trends: Automation and Smart Manufacturing

Automation and smart manufacturing are revolutionizing assembly lines by integrating robotics, AI, and IoT for enhanced precision and efficiency. Flexible Manufacturing Systems (FMS) incorporate modular automation and real-time data analytics to adapt quickly to changing production demands and customize outputs. Future trends emphasize increased connectivity, predictive maintenance, and AI-driven decision-making to optimize both assembly lines and FMS for greater scalability and responsiveness.

Related Important Terms

Modular Assembly Cells

Modular assembly cells in flexible manufacturing systems enable efficient production by allowing rapid reconfiguration of assembly processes to accommodate varying product designs and volumes, contrasting with the fixed sequence and limited adaptability of traditional assembly lines. This modularity enhances scalability, reduces downtime, and supports customization, making it ideal for dynamic manufacturing environments requiring quick transitions between different products.

Reconfigurable Manufacturing Systems (RMS)

Reconfigurable Manufacturing Systems (RMS) offer superior adaptability compared to traditional assembly lines by enabling rapid reconfiguration of equipment and processes to accommodate product customization and varied production volumes. Unlike flexible manufacturing systems that prioritize flexibility, RMS emphasize scalability, modularity, and quick responsiveness, reducing downtime and enhancing cost efficiency in dynamic manufacturing environments.

Digital Twin Assembly Line

Digital Twin Assembly Line technology enhances traditional assembly lines by creating real-time virtual replicas, enabling precise monitoring, predictive maintenance, and optimization of manufacturing processes. Unlike Flexible Manufacturing Systems, which emphasize adaptability through reconfigurable machinery, Digital Twins integrate IoT data and advanced analytics to improve efficiency and reduce downtime in fixed assembly environments.

Cyber-Physical Production Systems (CPPS)

Cyber-Physical Production Systems (CPPS) enhance flexible manufacturing systems by integrating real-time data analytics and adaptive control, enabling dynamic reconfiguration of assembly processes for increased efficiency and customization. Unlike traditional assembly lines, CPPS facilitate seamless communication between physical machinery and digital networks, optimizing production flow and minimizing downtime through predictive maintenance and autonomous decision-making.

Smart Jigs & Fixtures

Smart jigs and fixtures in assembly lines significantly enhance precision and throughput by automating positioning and alignment tasks, reducing human error. Flexible manufacturing systems integrate these intelligent tools with adaptable robotics, enabling rapid reconfiguration for varied product designs and smaller batch sizes, driving efficiency in customized production.

Collaborative Robotics (Cobot Integration)

Collaborative robotics (cobot integration) in assembly lines enhances precision and speed through consistent task automation, while flexible manufacturing systems utilize cobots for adaptive workflows that accommodate varying product designs and volumes. This synergy of cobots enables manufacturers to optimize productivity by combining repetitive task efficiency with agile, customizable production capabilities.

Adaptive Process Planning

Adaptive process planning in assembly lines emphasizes fixed sequences optimized for high-volume, repetitive tasks, while flexible manufacturing systems integrate dynamic routing and real-time adjustments to accommodate customized product variations and changing demand patterns. This flexibility enhances responsiveness and efficiency by leveraging modular equipment and advanced control algorithms for rapid adaptation in production workflows.

Automated Material Flow Optimization

Assembly lines enable efficient automated material flow through fixed, sequential processes designed for high-volume production, minimizing downtime and reducing manual handling. Flexible Manufacturing Systems (FMS) optimize automated material flow by integrating robotics and computer-controlled transport, allowing dynamic adjustments to product types and volumes while maintaining continuous material movement.

Mass Customization Line

Mass customization lines combine the efficiency of assembly lines with the adaptability of flexible manufacturing systems, enabling high-volume production of personalized products. This approach leverages modular equipment and real-time data integration to swiftly switch between product variants, optimizing both productivity and customization.

Agile Manufacturing Platforms

Assembly lines offer high-volume, repetitive production with limited customization, while flexible manufacturing systems (FMS) enable agile manufacturing platforms by integrating computer-controlled machines for rapid adaptation to product changes. Agile manufacturing platforms leverage FMS to minimize downtime, optimize workflow, and respond swiftly to market demand shifts, enhancing overall production efficiency.

Assembly Line vs Flexible Manufacturing System Infographic

industrydif.com

industrydif.com