Lean manufacturing emphasizes eliminating waste and optimizing processes to enhance efficiency and product quality, while frugal manufacturing focuses on minimizing cost and resource consumption by using simpler, affordable materials and methods. Both approaches aim to improve competitiveness, but lean prioritizes continuous improvement and precision, whereas frugal targets affordability and accessibility, especially in resource-constrained environments. Implementing lean manufacturing suits large-scale, high-volume production, whereas frugal manufacturing aligns with low-cost, flexible, and sustainable production models.

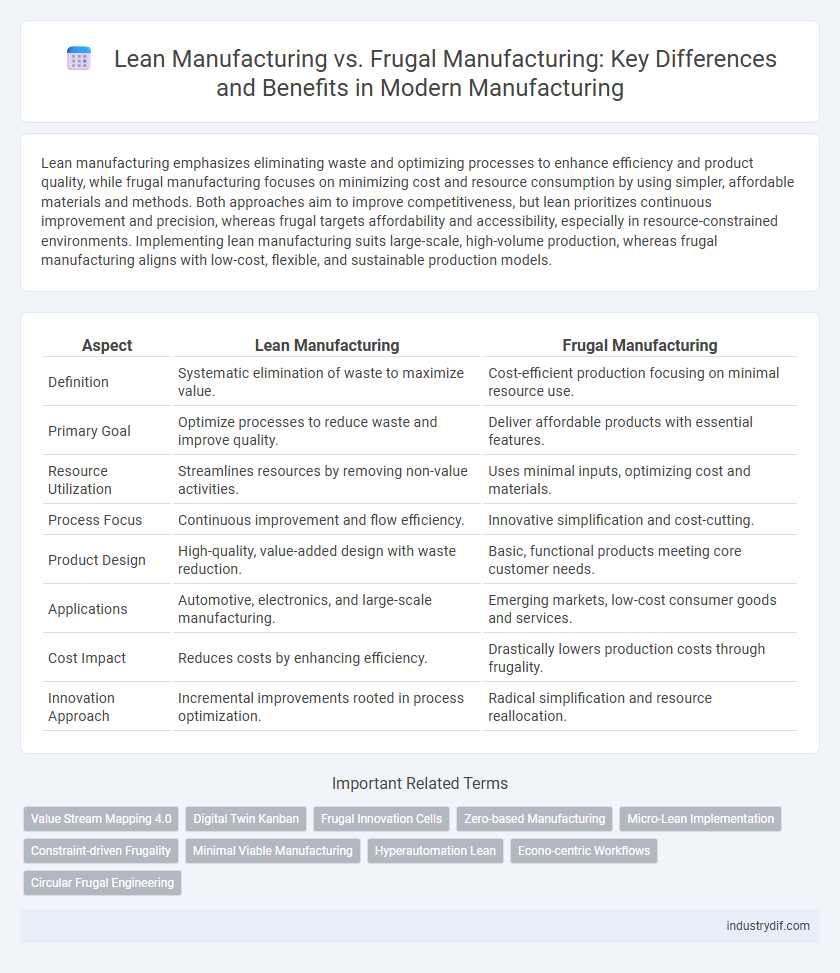

Table of Comparison

| Aspect | Lean Manufacturing | Frugal Manufacturing |

|---|---|---|

| Definition | Systematic elimination of waste to maximize value. | Cost-efficient production focusing on minimal resource use. |

| Primary Goal | Optimize processes to reduce waste and improve quality. | Deliver affordable products with essential features. |

| Resource Utilization | Streamlines resources by removing non-value activities. | Uses minimal inputs, optimizing cost and materials. |

| Process Focus | Continuous improvement and flow efficiency. | Innovative simplification and cost-cutting. |

| Product Design | High-quality, value-added design with waste reduction. | Basic, functional products meeting core customer needs. |

| Applications | Automotive, electronics, and large-scale manufacturing. | Emerging markets, low-cost consumer goods and services. |

| Cost Impact | Reduces costs by enhancing efficiency. | Drastically lowers production costs through frugality. |

| Innovation Approach | Incremental improvements rooted in process optimization. | Radical simplification and resource reallocation. |

Defining Lean Manufacturing and Frugal Manufacturing

Lean manufacturing emphasizes waste reduction by streamlining production processes to improve efficiency and quality while minimizing costs. Frugal manufacturing focuses on simplifying product design and using low-cost materials to create affordable, accessible goods without compromising essential functionality. Both approaches aim to optimize resource usage but prioritize different aspects of cost-saving and value creation in manufacturing.

Core Principles: Lean vs Frugal Approaches

Lean Manufacturing emphasizes waste elimination through continuous improvement, focusing on value-driven processes, just-in-time production, and employee empowerment to optimize efficiency. Frugal Manufacturing prioritizes cost-effectiveness by simplifying products, minimizing resource usage, and adapting processes to local constraints without heavy capital investment. Both approaches seek efficiency but differ in emphasis: Lean targets process perfection, while Frugal centers on resourcefulness and affordability.

Historical Evolution of Manufacturing Methodologies

Lean Manufacturing emerged in the mid-20th century, pioneered by Toyota's Production System to eliminate waste and improve efficiency through continuous improvement and just-in-time production. Frugal Manufacturing, gaining prominence in the 21st century, emphasizes cost-effective innovation and resource optimization, particularly suited for emerging markets with limited resources. The historical evolution reflects a shift from waste elimination in Lean to value-driven, affordable solutions in Frugal Manufacturing.

Key Differences in Resource Utilization

Lean manufacturing emphasizes minimizing waste and optimizing processes to increase efficiency, using techniques like just-in-time inventory and continuous improvement. Frugal manufacturing prioritizes cost reduction by simplifying production designs and using fewer or lower-cost materials, targeting affordability without sacrificing functionality. While lean focuses on process efficiency and waste elimination, frugal centers on resource savings through material and design constraints.

Waste Reduction Techniques Compared

Lean Manufacturing emphasizes eliminating waste through continuous improvement, focusing on techniques like Just-In-Time inventory, 5S organization, and value stream mapping to enhance efficiency. Frugal Manufacturing prioritizes cost-effectiveness by minimizing resource usage and optimizing processes to reduce material and energy waste without compromising product functionality. Both approaches target waste reduction but Lean centers on process refinement, while Frugal leverages simplicity and resourcefulness for sustainable manufacturing.

Impact on Product Quality and Consistency

Lean Manufacturing emphasizes continuous waste reduction and process standardization, resulting in consistent product quality and minimized defects. Frugal Manufacturing prioritizes cost-efficiency and resource optimization, which can sometimes lead to variability in materials or processes affecting consistency but encourages innovation for maintaining acceptable quality. Both methodologies impact product quality differently, with Lean focusing on uniformity and Frugal balancing quality with affordability.

Implementation Challenges and Solutions

Lean Manufacturing implementation faces challenges such as employee resistance to change and the need for continuous process improvement, which can be addressed through comprehensive training programs and fostering a culture of collaboration. Frugal Manufacturing struggles with balancing cost reduction and maintaining product quality, solvable by leveraging local resources and innovative design approaches to optimize efficiency. Both methodologies require strong leadership commitment and adaptive strategies to overcome operational hurdles effectively.

Cost Efficiency: Lean vs Frugal Metrics

Lean Manufacturing emphasizes minimizing waste and optimizing processes through value stream mapping and continuous improvement, often measured by metrics such as Overall Equipment Effectiveness (OEE) and cycle time reduction. Frugal Manufacturing prioritizes cost efficiency by simplifying product design and using low-cost materials while maintaining functionality, with metrics focused on cost-per-unit and resource utilization rates. Both approaches enhance cost efficiency but lean targets operational excellence, whereas frugal centers on affordability and resource-conscious innovation.

Case Studies: Lean vs Frugal in Action

Case studies comparing Lean Manufacturing and Frugal Manufacturing reveal distinct approaches to efficiency and cost reduction. Lean Manufacturing emphasizes waste elimination and continuous improvement exemplified by Toyota's production system, which maximizes value through streamlined processes. Frugal Manufacturing, demonstrated by companies like Tata Motors, focuses on affordable innovation by using scarce resources creatively to deliver cost-effective products for emerging markets.

Future Trends in Manufacturing Methodologies

Lean Manufacturing emphasizes waste reduction and continuous improvement to enhance efficiency, while Frugal Manufacturing prioritizes cost-effective solutions and resource optimization for affordability. Future trends in manufacturing methodologies are increasingly integrating digital technologies, such as IoT and AI, to further streamline processes and enable adaptive production systems. The convergence of lean principles with frugal innovation drives sustainable, resilient manufacturing models tailored to dynamic market demands.

Related Important Terms

Value Stream Mapping 4.0

Value Stream Mapping 4.0 enhances Lean Manufacturing by integrating real-time data analytics and IoT connectivity to identify waste and optimize production flows with high precision. In contrast, Frugal Manufacturing utilizes Value Stream Mapping 4.0 to prioritize cost efficiency and resource-saving techniques, streamlining processes while maintaining essential value delivery.

Digital Twin Kanban

Digital Twin Kanban enhances Lean Manufacturing by providing real-time visualization and data analytics to optimize workflow efficiency and reduce waste. In Frugal Manufacturing, Digital Twin Kanban supports cost-effective resource management and adaptive production planning, enabling minimal expenditure without compromising quality.

Frugal Innovation Cells

Frugal Innovation Cells in manufacturing streamline product development by emphasizing cost-efficiency, simplicity, and resourcefulness, contrasting with Lean Manufacturing's focus on waste reduction and continuous improvement. These cells foster rapid innovation in resource-constrained environments, driving affordable, high-quality solutions tailored for emerging markets.

Zero-based Manufacturing

Zero-based Manufacturing integrates principles from both Lean Manufacturing and Frugal Manufacturing by emphasizing the elimination of all non-essential processes and expenses from the ground up, ensuring maximum resource efficiency and cost reduction. This approach drives continuous improvement, waste minimization, and value creation through rigorous analysis and strategic allocation of every resource in the production cycle.

Micro-Lean Implementation

Micro-Lean Implementation in manufacturing emphasizes small-scale, continuous improvements to optimize processes, reduce waste, and enhance productivity with minimal resources. Frugal Manufacturing complements this approach by prioritizing cost-efficiency and resourcefulness, enabling companies to achieve operational excellence through lean principles applied at a granular level.

Constraint-driven Frugality

Constraint-driven frugality in manufacturing emphasizes optimizing resource use and minimizing waste by rigorously adapting processes to physical, financial, or environmental limitations, enhancing efficiency beyond traditional Lean Manufacturing's focus on eliminating non-value-added activities. While Lean Manufacturing targets continuous improvement and waste reduction across the value stream, Frugal Manufacturing integrates constraints as a strategic driver for innovation, enabling cost-effective production tailored to emerging markets and resource-scarce environments.

Minimal Viable Manufacturing

Lean Manufacturing emphasizes waste reduction and continuous improvement to enhance efficiency, while Frugal Manufacturing focuses on cost-effective, resource-constrained production methods. Minimal Viable Manufacturing integrates principles from both by delivering essential functionality with minimal resource input, ensuring swift market entry and scalable innovation.

Hyperautomation Lean

Hyperautomation Lean manufacturing integrates advanced AI-driven automation tools and IoT devices to streamline production processes and eliminate waste more efficiently than traditional lean methods. Frugal manufacturing emphasizes cost minimization and resource optimization but often lacks the comprehensive digital integration and scalability provided by Hyperautomation Lean systems in modern factories.

Econo-centric Workflows

Lean Manufacturing emphasizes waste elimination and continuous improvement to maximize efficiency and reduce costs, focusing on streamlining processes and inventory management. Frugal Manufacturing prioritizes cost-effective resource utilization and simplified production methods to achieve economical workflows that support small-scale, scalable operations in budget-sensitive markets.

Circular Frugal Engineering

Circular Frugal Engineering in manufacturing emphasizes resource efficiency by integrating Lean Manufacturing principles with frugal innovation to minimize waste and maximize product lifecycle sustainability. This approach reduces material costs and environmental impact through design strategies that promote reuse, recycling, and simplification without compromising quality or performance.

Lean Manufacturing vs Frugal Manufacturing Infographic

industrydif.com

industrydif.com