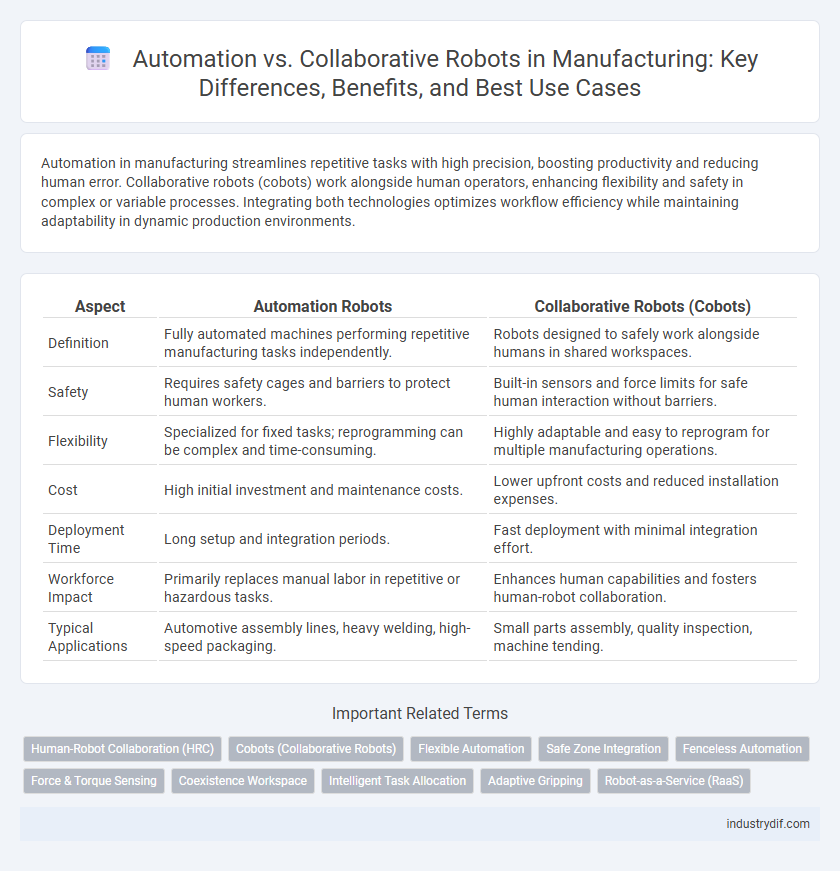

Automation in manufacturing streamlines repetitive tasks with high precision, boosting productivity and reducing human error. Collaborative robots (cobots) work alongside human operators, enhancing flexibility and safety in complex or variable processes. Integrating both technologies optimizes workflow efficiency while maintaining adaptability in dynamic production environments.

Table of Comparison

| Aspect | Automation Robots | Collaborative Robots (Cobots) |

|---|---|---|

| Definition | Fully automated machines performing repetitive manufacturing tasks independently. | Robots designed to safely work alongside humans in shared workspaces. |

| Safety | Requires safety cages and barriers to protect human workers. | Built-in sensors and force limits for safe human interaction without barriers. |

| Flexibility | Specialized for fixed tasks; reprogramming can be complex and time-consuming. | Highly adaptable and easy to reprogram for multiple manufacturing operations. |

| Cost | High initial investment and maintenance costs. | Lower upfront costs and reduced installation expenses. |

| Deployment Time | Long setup and integration periods. | Fast deployment with minimal integration effort. |

| Workforce Impact | Primarily replaces manual labor in repetitive or hazardous tasks. | Enhances human capabilities and fosters human-robot collaboration. |

| Typical Applications | Automotive assembly lines, heavy welding, high-speed packaging. | Small parts assembly, quality inspection, machine tending. |

Defining Automation in Modern Manufacturing

Automation in modern manufacturing refers to the use of advanced control systems, such as robotics, computer software, and sensors, to perform tasks with minimal human intervention, enhancing precision and efficiency. Industrial robots execute repetitive and hazardous operations, reducing error rates and improving product consistency. Collaborative robots (cobots) complement automation by working alongside human operators, enabling flexible production lines and boosting overall productivity.

What are Collaborative Robots (Cobots)?

Collaborative robots, or cobots, are advanced automation tools designed to work safely alongside human operators in manufacturing environments, enhancing productivity without extensive safety barriers. Equipped with sensors and adaptive programming, cobots perform repetitive or precision tasks such as assembly, packaging, and quality inspection, reducing human error and physical strain. Unlike traditional industrial robots, cobots offer flexibility and ease of integration, making them ideal for small and medium-sized enterprises seeking scalable automation solutions.

Key Differences: Automation vs Collaborative Robots

Automation systems perform repetitive, high-volume tasks with minimal human intervention, maximizing efficiency and consistency in manufacturing processes. Collaborative robots (cobots) are designed to work safely alongside humans, offering flexibility and adaptability in complex or variable tasks. Key differences include the level of human interaction, safety features, and application scope, with automation favoring isolated, large-scale production and cobots enhancing human-robot cooperation on assembly lines.

Advantages of Traditional Automation

Traditional automation delivers high-speed, consistent production with minimal human intervention, reducing labor costs and increasing throughput. It excels in repetitive, high-volume tasks where precision and reliability are critical, ensuring quality control across manufacturing processes. Established systems also benefit from extensive integration capabilities and proven durability in demanding industrial environments.

Benefits of Implementing Collaborative Robots

Collaborative robots, or cobots, enhance manufacturing efficiency by working safely alongside human operators, reducing downtime and increasing productivity. Their flexible programming and ease of integration allow for quick adaptation to varied tasks without extensive retooling. Implementing cobots leads to improved workplace safety, higher precision in repetitive processes, and accelerated production cycles.

Safety Considerations in Automation and Cobots

Automation systems in manufacturing enhance productivity but require stringent safety protocols to prevent hazards from high-speed machinery and limited human intervention. Collaborative robots (cobots) integrate safety features such as force-limited joints and advanced sensors to work safely alongside human operators without protective barriers. Ensuring compliance with ISO 10218 and ISO/TS 15066 standards is critical for minimizing risks and maintaining safe interactions between humans and automated systems.

Cost Efficiency: Automation Versus Cobots

Automation systems offer high initial investment costs but deliver substantial long-term savings through increased production rates and reduced labor expenses. Collaborative robots (cobots) require lower upfront costs and provide flexible deployment for small-batch or customized manufacturing, minimizing downtime and reprogramming expenses. Cost efficiency depends on production scale and complexity, with traditional automation favored for mass production and cobots ideal for agile, mixed-model environments.

Flexibility and Scalability in Manufacturing

Automation systems provide high scalability in manufacturing through programmable processes and advanced robotics, enabling rapid production increases with minimal downtime. Collaborative robots (cobots) offer superior flexibility by working safely alongside human operators, easily adapting to varied tasks and small batch sizes without extensive reprogramming. Combining scalable automation with the adaptable nature of cobots enhances manufacturing efficiency, allowing dynamic shifts in production volume and product customization.

Workforce Impact and Human-Robot Collaboration

Automation in manufacturing significantly boosts productivity by performing repetitive tasks with high precision, reducing human error and operational costs. Collaborative robots (cobots) enhance workforce impact by working alongside human operators, improving flexibility and safety while enabling skill augmentation rather than replacement. These human-robot collaborations foster increased efficiency, job satisfaction, and innovation potential within production environments.

Future Trends: Automation and Collaborative Robotics

The future of manufacturing is rapidly advancing with automation and collaborative robots (cobots) enhancing operational efficiency and flexibility. Automation systems are becoming increasingly intelligent with AI integration, enabling predictive maintenance and real-time process optimization. Collaborative robots are evolving to safely work alongside human operators, offering adaptive, easy-to-program solutions that expand their use across small and medium enterprises.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) enhances manufacturing efficiency by integrating automation with collaborative robots that work safely alongside human operators, optimizing production tasks without compromising safety. This synergy reduces downtime and increases flexibility, enabling real-time adaptability on assembly lines and improving overall operational productivity.

Cobots (Collaborative Robots)

Cobots enhance manufacturing efficiency by working safely alongside human operators, providing flexibility and precision in tasks such as assembly, inspection, and packaging. Unlike traditional automation, cobots are designed for easy programming and adaptability, reducing setup time and enabling rapid deployment in dynamic manufacturing environments.

Flexible Automation

Flexible automation integrates automated systems capable of adapting to varied tasks without extensive reprogramming, enhancing efficiency in manufacturing processes. Collaborative robots (cobots) complement this by providing human-robot interaction, enabling flexible deployment in complex or variable production environments where adaptability is crucial.

Safe Zone Integration

Automation in manufacturing enhances productivity through fully autonomous systems, while collaborative robots (cobots) prioritize safe zone integration by operating alongside human workers without extensive safety barriers; the use of advanced sensors and real-time monitoring ensures seamless interaction within designated safe zones, reducing downtime and increasing operational efficiency. Implementing safe zone integration in cobots facilitates flexible task allocation and rapid adaptation to production changes, optimizing labor utilization and minimizing workplace hazards.

Fenceless Automation

Fenceless automation integrates advanced sensors and AI to enable collaborative robots (cobots) to operate safely alongside human workers without physical barriers, enhancing flexibility and workspace efficiency in manufacturing environments. This approach reduces downtime and facilitates rapid reconfiguration of production lines, driving productivity while maintaining stringent safety standards.

Force & Torque Sensing

Force and torque sensing in collaborative robots enables precise, real-time interaction with human operators, enhancing safety and adaptability in manufacturing environments. Automation systems relying on fixed robots often lack the nuanced force feedback essential for sensitive tasks, making collaborative robots with advanced tactile sensors more suited for complex assembly and quality control processes.

Coexistence Workspace

Automation in manufacturing streamlines repetitive tasks through programmed machinery, while collaborative robots (cobots) enhance flexibility by working safely alongside human operators within coexistence workspaces. These hybrid environments optimize productivity and safety by combining high-precision automation with the adaptive decision-making of human workers, leveraging advanced sensors and AI for seamless interaction.

Intelligent Task Allocation

Automation utilizes programmed systems to perform repetitive tasks with high precision, while collaborative robots (cobots) enhance intelligent task allocation by dynamically interacting with human workers to optimize workflow efficiency. Intelligent task allocation in manufacturing integrates real-time data analytics and machine learning algorithms, enabling cobots to adjust roles based on task complexity and human skill levels, improving productivity and reducing downtime.

Adaptive Gripping

Adaptive gripping technology in collaborative robots enhances precision and flexibility by adjusting grip strength and shape to handle diverse manufacturing components with minimal human intervention. Unlike traditional automation, these smart grippers increase efficiency and reduce product damage by dynamically responding to material variations and complex assembly tasks.

Robot-as-a-Service (RaaS)

Robot-as-a-Service (RaaS) offers manufacturers scalable access to automation through subscription-based collaborative robots that enhance flexibility and reduce upfront capital expenditure. This model accelerates integration in production lines by combining autonomous functions with human teamwork, optimizing efficiency and minimizing downtime.

Automation vs Collaborative Robots Infographic

industrydif.com

industrydif.com