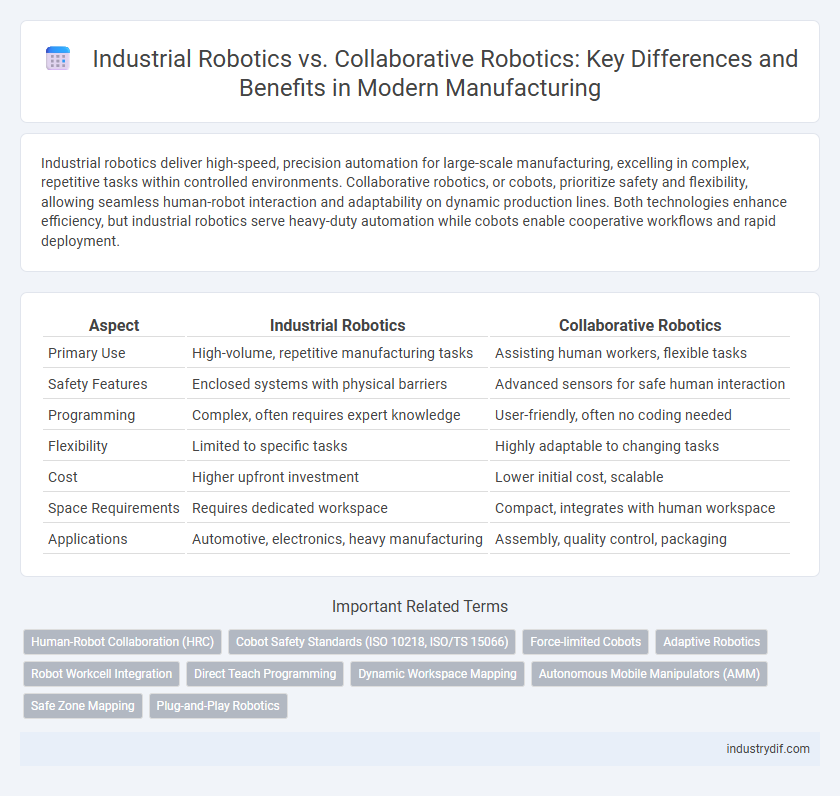

Industrial robotics deliver high-speed, precision automation for large-scale manufacturing, excelling in complex, repetitive tasks within controlled environments. Collaborative robotics, or cobots, prioritize safety and flexibility, allowing seamless human-robot interaction and adaptability on dynamic production lines. Both technologies enhance efficiency, but industrial robotics serve heavy-duty automation while cobots enable cooperative workflows and rapid deployment.

Table of Comparison

| Aspect | Industrial Robotics | Collaborative Robotics |

|---|---|---|

| Primary Use | High-volume, repetitive manufacturing tasks | Assisting human workers, flexible tasks |

| Safety Features | Enclosed systems with physical barriers | Advanced sensors for safe human interaction |

| Programming | Complex, often requires expert knowledge | User-friendly, often no coding needed |

| Flexibility | Limited to specific tasks | Highly adaptable to changing tasks |

| Cost | Higher upfront investment | Lower initial cost, scalable |

| Space Requirements | Requires dedicated workspace | Compact, integrates with human workspace |

| Applications | Automotive, electronics, heavy manufacturing | Assembly, quality control, packaging |

Introduction to Industrial and Collaborative Robotics

Industrial robotics involves automated machines designed for high-speed, precise tasks in manufacturing environments, often operating in isolated cells for safety. Collaborative robotics, or cobots, are built to work safely alongside human operators, enhancing flexibility and productivity through interactive programming and adaptive sensors. Both technologies drive efficiency but differ significantly in application scope, safety features, and integration within production lines.

Key Differences Between Industrial and Collaborative Robots

Industrial robotics typically involve large, powerful machines designed for high-speed, repetitive tasks in isolated environments, emphasizing precision and heavy-duty operations. Collaborative robots, or cobots, prioritize safety and flexibility, working alongside human operators with built-in sensors and force limits to prevent accidents. Key differences include their operational workspace, with industrial robots usually enclosed and cobots sharing the same space, and their programming complexity, where cobots often feature user-friendly interfaces for quick adaptation.

Applications in Modern Manufacturing

Industrial robotics dominate high-volume, repetitive manufacturing tasks such as welding, assembly, and material handling, excelling in environments requiring speed, precision, and endurance. Collaborative robotics, or cobots, integrate seamlessly with human workers on assembly lines, quality control, and packaging, enhancing flexibility and safety in small-batch and customized production. Both types optimize manufacturing efficiency by addressing distinct operational needs--industrial robots for heavy-duty automation and collaborative robots for adaptive, interactive tasks.

Safety Features: Traditional vs Collaborative Robotics

Industrial robotics prioritize safety through physical barriers, safety cages, and emergency stop mechanisms to prevent worker contact with powerful, high-speed machines. Collaborative robotics integrate advanced sensors, force limiters, and real-time monitoring systems allowing safe human-robot interaction within shared workspaces without rigid guarding. This shift in safety features enhances workplace flexibility and reduces risk while maintaining compliance with standards like ISO 10218 and ISO/TS 15066.

Deployment and Integration in Factories

Industrial robotics typically require extensive deployment periods due to complex integration with existing factory automation systems and specialized programming for high-volume, repetitive tasks. Collaborative robotics offer faster deployment with user-friendly interfaces and easier integration alongside human workers, enabling flexible adaptation in diverse production environments. Factories benefit from combining industrial robots for heavy-duty operations and collaborative robots for precision tasks, optimizing overall manufacturing efficiency and scalability.

Cost Considerations for Robotics Adoption

Industrial robotics typically involve higher initial capital investment due to complex machinery and extensive infrastructure requirements, while collaborative robots (cobots) offer lower upfront costs with simpler integration and flexible deployment. Maintenance expenses for industrial robots can be substantial due to their heavy-duty applications, whereas cobots require less specialized servicing, reducing long-term operational costs. Total cost of ownership analysis often favors cobots for small-to-medium enterprises aiming for scalable automation without extensive upfront financial burden.

Flexibility and Scalability in Manufacturing Processes

Industrial robotics offer high precision and speed optimized for repetitive, large-scale manufacturing tasks but often require significant reprogramming for new applications. Collaborative robotics (cobots) provide enhanced flexibility by safely working alongside human operators, enabling rapid adaptation to varied tasks and easier scalability in production lines. Implementing cobots maximizes operational agility while maintaining safety, essential for manufacturers facing frequent product changes and small batch sizes.

Productivity and Efficiency Gains

Industrial robotics excel in high-volume, repetitive tasks by maximizing speed and precision, leading to significant productivity gains in large-scale manufacturing. Collaborative robotics enhance efficiency by working safely alongside human operators, enabling flexible automation and reducing downtime from complex changeovers. Combining both systems optimizes production lines, balancing robustness with adaptability to achieve superior operational performance.

Human-Robot Interaction in the Workplace

Industrial robotics typically operate in isolated environments with minimal human interaction, ensuring safety through physical barriers and predefined programming. Collaborative robotics (cobots) enhance human-robot interaction by working alongside employees, equipped with advanced sensors and AI to adapt in real-time. This integration improves workflow efficiency and reduces ergonomic strain while maintaining high safety standards in manufacturing settings.

Future Trends in Robotics for Manufacturing

Industrial robotics continue to advance with increased precision, speed, and integration of artificial intelligence to optimize high-volume production environments. Collaborative robotics, or cobots, are rapidly evolving to enhance safety features and adaptive capabilities, allowing seamless human-robot interaction on factory floors. Future trends emphasize hybrid robotic systems that combine the strengths of industrial and collaborative robots to boost flexibility, efficiency, and scalability in smart manufacturing ecosystems.

Related Important Terms

Human-Robot Collaboration (HRC)

Industrial robotics excel in high-speed, repetitive tasks within isolated environments, while collaborative robotics prioritize Human-Robot Collaboration (HRC) through embedded safety features and intuitive interfaces, enabling seamless interaction alongside human operators on the manufacturing floor. HRC enhances efficiency and ergonomics by combining robotic precision with human adaptability, crucial for tasks requiring flexibility and real-time decision-making in smart factories.

Cobot Safety Standards (ISO 10218, ISO/TS 15066)

Industrial robotics primarily operate in segregated environments with ISO 10218 standards emphasizing rigorous safety measures to prevent human-robot interactions, while collaborative robotics, guided by ISO/TS 15066, focus on real-time safety features such as force and speed limits to enable safe human-robot collaboration. Compliance with these standards ensures cobots incorporate advanced sensors and control systems to minimize injury risks, optimizing productivity and workplace safety in manufacturing settings.

Force-limited Cobots

Force-limited cobots in manufacturing enhance safety by automatically stopping or reducing force upon detecting unexpected contact, allowing seamless human-robot collaboration without protective barriers. Unlike traditional industrial robots that require guarded environments, these collaborative robots optimize productivity and flexibility in complex assembly tasks through advanced sensors and real-time force control.

Adaptive Robotics

Industrial robotics excels in high-volume, repetitive manufacturing tasks with precise automation, while collaborative robotics emphasizes safety and flexibility by working alongside human operators. Adaptive robotics enhances both paradigms by integrating advanced sensors, AI algorithms, and machine learning to dynamically adjust operations, improving efficiency and responsiveness in complex manufacturing environments.

Robot Workcell Integration

Industrial robotics in manufacturing typically involves fully automated, high-speed robot workcell integration designed for repetitive, heavy-duty tasks requiring precise control and safety isolation. Collaborative robotics emphasizes flexible robot workcell integration that allows humans and robots to work side-by-side safely, enhancing adaptability and quick task switching in assembly and inspection processes.

Direct Teach Programming

Industrial robotics typically utilize traditional programming methods requiring expert operators to code complex sequences, whereas collaborative robotics emphasize Direct Teach Programming that enables operators to physically guide robots through tasks, reducing setup time and enhancing flexibility. Direct Teach Programming in collaborative robots facilitates safer human-robot interaction by allowing intuitive task learning without extensive coding knowledge, optimizing manufacturing processes in dynamic production environments.

Dynamic Workspace Mapping

Industrial robotics rely on fixed, pre-programmed paths which limit adaptability in dynamic workspace mapping, whereas collaborative robotics utilize advanced sensors and AI to continuously map and adjust to changing environments. This real-time spatial awareness enhances safety and operational flexibility, enabling seamless human-robot interaction in manufacturing settings.

Autonomous Mobile Manipulators (AMM)

Autonomous Mobile Manipulators (AMM) integrate mobility and dexterous manipulation, enabling industrial robotics to perform complex tasks across varied manufacturing environments with higher efficiency than traditional stationary robots. Collaborative robotics enhance AMMs with advanced sensors and AI, allowing safe interaction alongside human workers while maintaining precision and adaptability in dynamic production lines.

Safe Zone Mapping

Industrial robotics typically operate within fixed Safe Zone Mappings defined by physical barriers and safety sensors to prevent human intrusion during high-speed, heavy-duty tasks. Collaborative robotics utilize dynamic Safe Zone Mapping with advanced sensors and AI to detect and adapt to human presence in real-time, enabling safe interaction without physical barriers.

Plug-and-Play Robotics

Industrial robotics systems deliver high-speed, high-precision automation suited for repetitive tasks in large-scale manufacturing environments, often requiring extensive programming and safety measures. Collaborative robotics emphasize plug-and-play robotics features, enabling easy integration and flexible deployment alongside human workers without complex setup or safeguarding barriers.

Industrial Robotics vs Collaborative Robotics Infographic

industrydif.com

industrydif.com