Batch production involves manufacturing products in fixed quantities, optimizing efficiency and reducing setup times for medium to large volumes. Lot-size-one production customizes each item individually, offering maximum flexibility and responsiveness for highly personalized orders. Choosing between these methods depends on the balance between production cost, lead time, and product customization requirements.

Table of Comparison

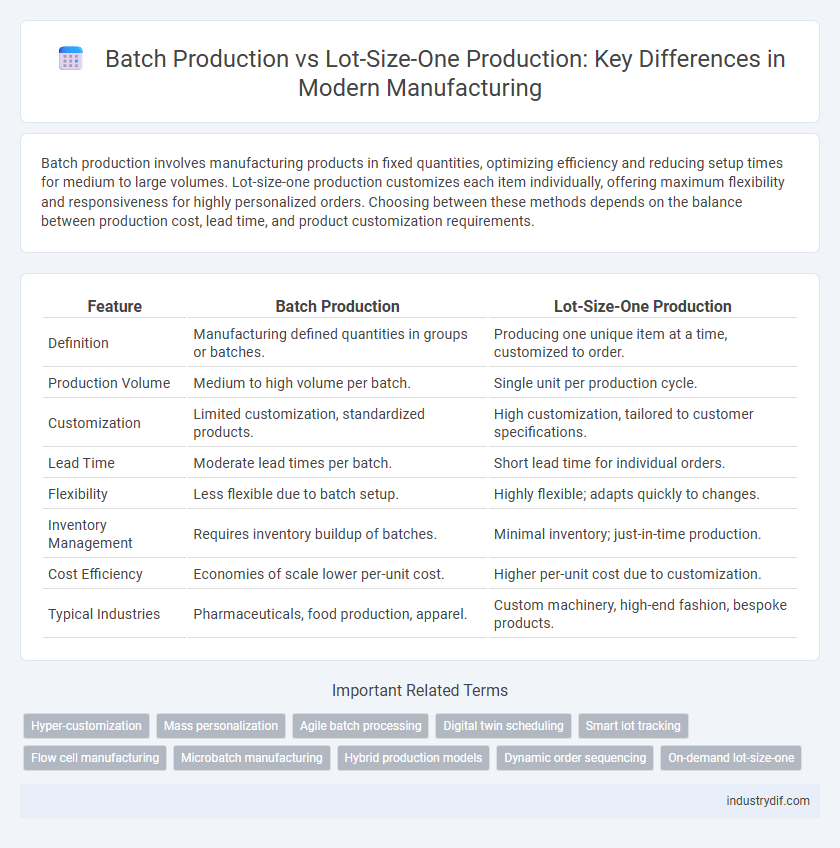

| Feature | Batch Production | Lot-Size-One Production |

|---|---|---|

| Definition | Manufacturing defined quantities in groups or batches. | Producing one unique item at a time, customized to order. |

| Production Volume | Medium to high volume per batch. | Single unit per production cycle. |

| Customization | Limited customization, standardized products. | High customization, tailored to customer specifications. |

| Lead Time | Moderate lead times per batch. | Short lead time for individual orders. |

| Flexibility | Less flexible due to batch setup. | Highly flexible; adapts quickly to changes. |

| Inventory Management | Requires inventory buildup of batches. | Minimal inventory; just-in-time production. |

| Cost Efficiency | Economies of scale lower per-unit cost. | Higher per-unit cost due to customization. |

| Typical Industries | Pharmaceuticals, food production, apparel. | Custom machinery, high-end fashion, bespoke products. |

Introduction to Production Methods

Batch production involves manufacturing fixed quantities of a product in groups or batches, optimizing efficiency through standardized processes and equipment setups. Lot-size-one production, also known as single-piece flow, focuses on producing customized items individually, prioritizing flexibility and rapid response to specific customer requirements. Understanding these production methods helps manufacturers balance cost, lead time, and product variety to meet market demands effectively.

Defining Batch Production

Batch production is a manufacturing process where products are produced in specific groups or quantities, allowing for efficient handling of similar items through standardized workflows. This method enables companies to balance flexibility and volume by minimizing setup changes while accommodating product variations within each batch. Batch production is ideal for industries requiring moderate customization and demand fluctuations, such as pharmaceuticals, food processing, and electronics.

Understanding Lot-Size-One Production

Lot-size-one production refers to manufacturing processes tailored to produce a single unit or highly customized items per batch, emphasizing flexibility and personalization. This approach contrasts with batch production, which creates multiple identical units in groups to optimize efficiency and reduce costs. Understanding lot-size-one production is critical for industries requiring bespoke products, as it enables rapid adaptation to specific customer requirements without extensive setup times.

Key Differences: Batch vs Lot-Size-One

Batch production manufactures a fixed quantity of identical products in groups, optimizing efficiency and reducing setup time for recurring orders. Lot-size-one production customizes each unit individually, prioritizing flexibility and meeting unique customer specifications without economies of scale. Key differences include batch production's lower per-unit cost for standardized products versus lot-size-one's higher adaptability for bespoke manufacturing processes.

Advantages of Batch Production

Batch production offers significant advantages in manufacturing by enabling efficient utilization of machinery and labor through the production of multiple units in a single run, which reduces setup times and overall production costs. This method improves inventory management by allowing companies to stock standardized quantities, facilitating demand forecasting and reducing stockouts. Furthermore, batch production enhances quality control by enabling inspection at various stages, minimizing defects before moving to subsequent batches.

Benefits of Lot-Size-One Manufacturing

Lot-size-one manufacturing enhances customization by enabling tailored production for individual customer requirements, reducing inventory costs and minimizing waste. This method improves agility and responsiveness in manufacturing processes, allowing companies to quickly adapt to market changes and specific demands. Enhanced product quality and customer satisfaction result from precise control over each unit, fostering stronger client relationships and competitive advantage.

Flexibility and Customization Comparison

Batch production offers moderate flexibility by producing items in groups, allowing some customization within each batch but limiting responsiveness to individual customer demands. Lot-size-one production maximizes flexibility and customization, enabling manufacturers to produce unique, made-to-order items efficiently without the constraints of large batch runs. This approach supports rapid adjustments to design changes and customer preferences, making it ideal for industries that require personalized products.

Impact on Manufacturing Efficiency

Batch production enhances manufacturing efficiency by streamlining processes and reducing setup times for similar products, enabling economies of scale and minimizing downtime. Lot-size-one production increases flexibility and customization but often results in higher per-unit costs and longer cycle times due to frequent changeovers. Choosing between batch production and lot-size-one production depends on balancing efficiency goals with product variety and customer demand.

Cost Implications in Each Production Model

Batch production benefits from economies of scale, reducing per-unit costs by producing items in large quantities with standardized processes, which lowers setup and labor expenses. Lot-size-one production, or customized manufacturing, incurs higher costs due to frequent changeovers, increased labor intensity, and limited scope for process automation. Understanding these cost implications helps manufacturers choose the optimal production model aligned with product complexity and market demand.

Choosing the Right Production Strategy

Selecting the right production strategy between batch production and lot-size-one production depends on factors like demand variability, product complexity, and cost efficiency. Batch production is ideal for moderate volumes with consistent demand, optimizing setup times and reducing per-unit costs. Lot-size-one production suits customized, high-variation products, enabling flexibility and responsiveness despite higher production costs.

Related Important Terms

Hyper-customization

Batch production efficiently handles moderate volumes with consistent specifications, enabling standardized processes but limiting flexibility for unique customer demands. Lot-size-one production supports hyper-customization by manufacturing individual units tailored precisely to specific customer requirements, optimizing agility and personalization at the expense of higher complexity and cost.

Mass personalization

Batch production efficiently handles standardized goods in large quantities, while lot-size-one production enables mass personalization by producing customized products tailored to individual customer specifications. Embracing digital manufacturing and flexible automation allows companies to scale lot-size-one production without sacrificing cost-effectiveness or speed.

Agile batch processing

Agile batch processing enhances flexibility in manufacturing by enabling smaller, customizable batch sizes that reduce lead times and inventory costs compared to traditional batch production. Lot-size-one production prioritizes individualized orders but benefits from Agile batch methods by balancing efficiency with responsiveness to rapid market changes.

Digital twin scheduling

Batch production enables efficient manufacturing of identical products by grouping tasks, while lot-size-one production prioritizes customization and flexibility for individual units. Digital twin scheduling enhances both methods by creating real-time simulated environments that optimize resource allocation, minimize downtime, and improve production accuracy.

Smart lot tracking

Smart lot tracking enhances batch production by enabling precise monitoring of inventory, quality control, and production timelines, reducing waste and improving efficiency. In lot-size-one production, this technology facilitates real-time customization and traceability, supporting agile manufacturing and minimizing errors in personalized orders.

Flow cell manufacturing

Flow cell manufacturing in batch production enables efficient handling of uniform product groups, reducing setup times and maximizing throughput by processing items in defined batches. Conversely, lot-size-one production tailors manufacturing to unique, customer-specific orders, offering flexibility and customization at the expense of lower volume efficiency and higher per-unit costs.

Microbatch manufacturing

Microbatch manufacturing offers a flexible approach within batch production by enabling smaller, customized batch sizes that reduce lead times and minimize inventory costs. This method contrasts with lot-size-one production, which focuses on single-unit customization but often results in higher per-unit costs and longer setup times.

Hybrid production models

Hybrid production models combine the efficiency of batch production with the customization capabilities of lot-size-one production, enabling manufacturers to optimize resource utilization while meeting diverse customer demands. By integrating flexible tooling and modular processes, these models reduce setup times and improve responsiveness, resulting in cost-effective production cycles and enhanced product variety.

Dynamic order sequencing

Dynamic order sequencing in batch production optimizes workflow by grouping similar items to reduce setup times and enhance efficiency, while lot-size-one production prioritizes customization and flexibility by sequencing orders individually to meet specific customer demands. Implementing dynamic sequencing strategies improves resource allocation and minimizes lead times in both batch and lot-size-one environments.

On-demand lot-size-one

On-demand lot-size-one production enables manufacturers to produce customized products individually, minimizing inventory costs and reducing waste compared to traditional batch production methods. This approach enhances flexibility and responsiveness to specific customer demands while optimizing resource use and lead times.

Batch Production vs Lot-Size-One Production Infographic

industrydif.com

industrydif.com