Discrete manufacturing involves producing distinct, countable products through assembly lines and machining processes, emphasizing mass production of identical items. Additive manufacturing, or 3D printing, builds objects layer by layer from digital models, enabling complex geometries and customization with minimal material waste. While discrete manufacturing excels in efficiency for large volumes, additive manufacturing offers flexibility and rapid prototyping for specialized, low-volume production.

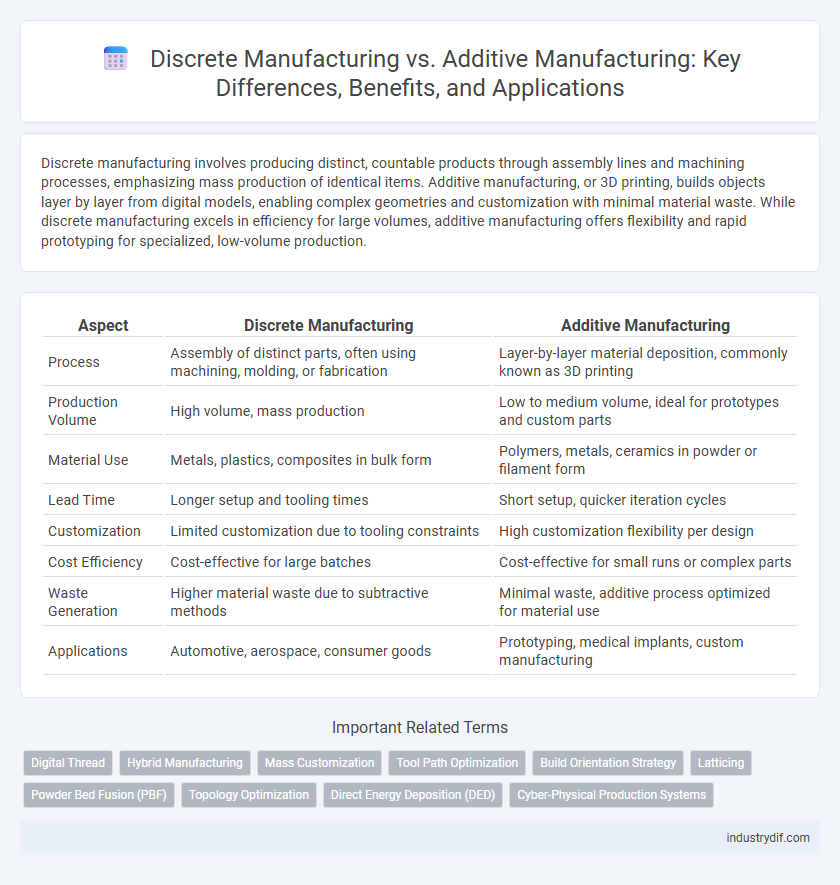

Table of Comparison

| Aspect | Discrete Manufacturing | Additive Manufacturing |

|---|---|---|

| Process | Assembly of distinct parts, often using machining, molding, or fabrication | Layer-by-layer material deposition, commonly known as 3D printing |

| Production Volume | High volume, mass production | Low to medium volume, ideal for prototypes and custom parts |

| Material Use | Metals, plastics, composites in bulk form | Polymers, metals, ceramics in powder or filament form |

| Lead Time | Longer setup and tooling times | Short setup, quicker iteration cycles |

| Customization | Limited customization due to tooling constraints | High customization flexibility per design |

| Cost Efficiency | Cost-effective for large batches | Cost-effective for small runs or complex parts |

| Waste Generation | Higher material waste due to subtractive methods | Minimal waste, additive process optimized for material use |

| Applications | Automotive, aerospace, consumer goods | Prototyping, medical implants, custom manufacturing |

Definition of Discrete Manufacturing

Discrete manufacturing refers to the process of producing distinct, countable items such as automobiles, appliances, or electronics through assembly lines and component fabrication. It involves the transformation of raw materials into finished goods by assembling individual parts, emphasizing production of tangible products with identifiable units. This method contrasts with additive manufacturing by relying on subtractive processes and assembly techniques rather than layer-by-layer material deposition.

Definition of Additive Manufacturing

Additive Manufacturing is a process of creating three-dimensional objects by successively layering materials based on digital models, enabling complex geometries and custom designs unattainable through traditional methods. Unlike Discrete Manufacturing, which involves assembling separate components, Additive Manufacturing builds products directly, often using materials such as polymers, metals, or ceramics. This technology enhances prototyping speed, reduces waste, and allows for on-demand production in aerospace, automotive, and medical industries.

Key Differences Between Discrete and Additive Manufacturing

Discrete manufacturing involves the production of distinct, countable units such as cars, appliances, or electronics using traditional subtractive processes like machining and assembly lines. Additive manufacturing, commonly known as 3D printing, builds objects layer by layer from digital models, enabling complex geometries and rapid prototyping with materials like plastics, metals, and composites. Key differences include production volume, customization capabilities, material utilization efficiency, and lead time, with discrete manufacturing optimized for mass production and additive manufacturing excelling in bespoke, low-volume, or intricate component fabrication.

Materials Used in Discrete vs Additive Manufacturing

Discrete manufacturing primarily utilizes metals, plastics, and composites such as steel, aluminum, and thermoplastics, selected for their strength, durability, and machinability in processes like stamping, molding, and assembly. Additive manufacturing, or 3D printing, often relies on specialized materials including photopolymers, metal powders (titanium, stainless steel), and engineered thermoplastics like ABS and nylon, optimized for layer-by-layer fabrication and complex geometries. Material selection in both manufacturing types is driven by functional requirements, cost efficiency, and compatibility with respective production methods.

Process Workflow Comparison

Discrete manufacturing involves assembling individual components through sequential processes like machining, welding, and quality checks, resulting in distinct, separate products. Additive manufacturing builds products layer by layer directly from digital models, minimizing material waste and enabling complex geometries without tooling changes. The workflow in discrete manufacturing emphasizes inventory management and assembly line efficiency, while additive manufacturing prioritizes digital design optimization and on-demand production flexibility.

Production Speed and Scalability

Discrete manufacturing offers faster production speeds for high-volume, standardized parts due to established assembly lines and automation, making it ideal for mass production. Additive manufacturing excels in scalability for complex, custom, or low-volume parts, allowing rapid prototyping and flexible adjustments without extensive tooling. Production speed in additive manufacturing depends on build size and complexity, often slower but more adaptable than discrete methods in responding to design changes.

Cost Considerations in Both Methods

Discrete manufacturing involves higher initial tooling and setup costs but generally offers lower per-unit production expenses for large volumes due to economies of scale. Additive manufacturing reduces investment in tooling and allows for cost-effective production of complex or customized parts in small batches, although its per-unit cost remains higher at scale. Evaluating cost efficiency depends on production volume, complexity, and the level of customization required in each manufacturing method.

Quality Control and Precision

Discrete manufacturing employs established quality control processes like Statistical Process Control (SPC) and Six Sigma to ensure high precision in mass production of components such as automotive parts and electronics. Additive manufacturing leverages layer-by-layer construction with real-time monitoring technologies like in-situ sensors and machine learning algorithms to achieve precise dimensional accuracy and complex geometries, often used in aerospace and medical implants. While discrete manufacturing emphasizes repeatability and defect minimization through rigid control systems, additive manufacturing focuses on adaptive quality assurance to manage variability inherent in material deposition processes.

Typical Applications and Industries

Discrete manufacturing typically serves industries such as automotive, aerospace, and electronics, focusing on producing distinct, countable products like machinery, vehicles, and electronic devices. Additive manufacturing finds applications in prototyping, custom medical implants, aerospace components, and complex tooling, enabling rapid production of intricate designs and reducing material waste. Both methods cater to industries requiring precision and customization but differ in production volume and complexity.

Future Trends in Manufacturing Technologies

Future trends in manufacturing technologies emphasize the integration of additive manufacturing with discrete manufacturing processes to enhance customization and reduce production lead times. Advanced materials and AI-driven design software are enabling additive manufacturing to create complex, lightweight components that traditional discrete methods cannot easily produce. The convergence of these technologies supports smart factories and Industry 4.0 initiatives, driving efficiency, flexibility, and sustainability in manufacturing operations.

Related Important Terms

Digital Thread

Discrete manufacturing relies heavily on the digital thread to integrate design, production, and quality data across complex assembly lines, enabling real-time tracking and process optimization. Additive manufacturing leverages the digital thread to seamlessly connect 3D design files with layer-by-layer production data, enhancing customization, reducing lead times, and ensuring traceability throughout the build process.

Hybrid Manufacturing

Hybrid manufacturing combines discrete manufacturing's precision and repeatability with additive manufacturing's design flexibility and material efficiency, enabling complex part production with reduced lead times. This integrated approach optimizes overall manufacturing performance by leveraging 3D printing for intricate geometries and subtractive methods for tight tolerances and surface finishes.

Mass Customization

Discrete manufacturing produces distinct, countable products through assembly lines, ideal for high-volume standardization, while additive manufacturing enables mass customization by building complex, personalized items layer by layer with minimal tooling changes. This flexibility in additive manufacturing supports rapid design iterations and efficient production of tailored products, meeting diverse customer specifications without sacrificing scalability.

Tool Path Optimization

Tool path optimization in discrete manufacturing focuses on minimizing machine movements and cycle times for subtractive processes such as CNC machining, enhancing precision and efficiency. In additive manufacturing, tool path optimization prioritizes layer deposition strategies and material usage to reduce print time and improve surface quality.

Build Orientation Strategy

Build orientation strategy in discrete manufacturing typically emphasizes maximizing machine uptime and minimizing setup times by arranging parts for efficient batch processing, while additive manufacturing focuses on optimizing part orientation to reduce support material, improve surface finish, and enhance mechanical properties. Strategic orientation in additive processes is critical for achieving dimensional accuracy and layer adhesion, directly impacting the quality and performance of the final product.

Latticing

Discrete manufacturing involves producing distinct items through subtractive processes, while additive manufacturing builds objects layer-by-layer using materials like metals or polymers. Latticing in additive manufacturing enhances structural integrity and reduces weight by creating complex internal frameworks that are impossible to achieve with traditional discrete methods.

Powder Bed Fusion (PBF)

Powder Bed Fusion (PBF) in additive manufacturing enables the creation of complex geometries and customized parts layer by layer using fine metal powders, offering superior design flexibility compared to traditional discrete manufacturing methods that rely on subtractive processes and standard tooling. PBF significantly reduces material waste and lead times, making it ideal for low-volume, high-precision production in aerospace, medical, and automotive industries.

Topology Optimization

Topology optimization in discrete manufacturing focuses on refining existing CAD models to enhance part performance and reduce material usage, while additive manufacturing leverages topology optimization to create complex, lightweight structures unachievable through traditional subtractive methods. Integrating topology optimization with additive manufacturing accelerates the production of custom, high-strength components, optimizing material distribution and enabling innovative designs that improve efficiency and reduce waste.

Direct Energy Deposition (DED)

Direct Energy Deposition (DED) in additive manufacturing enables precise layer-by-layer metal fabrication, offering superior repair and customization capabilities compared to traditional discrete manufacturing that relies on subtractive processes and assembly lines. DED's ability to deposit material directly onto complex geometries reduces waste and accelerates production cycles, making it ideal for aerospace and automotive component manufacturing.

Cyber-Physical Production Systems

Cyber-Physical Production Systems (CPPS) enhance Discrete Manufacturing by integrating real-time data analytics and automation for precise assembly lines. In Additive Manufacturing, CPPS enable adaptive control and in-process monitoring, improving customization, quality assurance, and resource efficiency during layer-by-layer fabrication.

Discrete Manufacturing vs Additive Manufacturing Infographic

industrydif.com

industrydif.com