Just-in-Time (JIT) manufacturing minimizes inventory costs by producing goods only as they are needed, enhancing efficiency and reducing waste. In contrast, Just-in-Case (JIC) emphasizes maintaining higher inventory levels to safeguard against supply chain disruptions and sudden demand spikes. Balancing JIT's lean approach with JIC's risk management is crucial for optimizing production continuity and responsiveness.

Table of Comparison

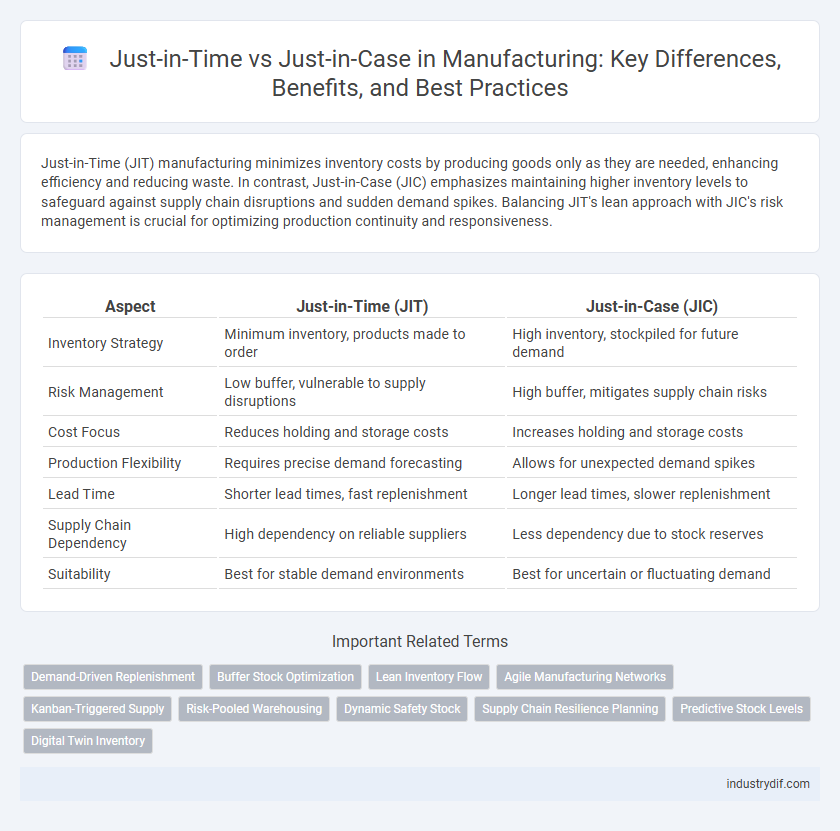

| Aspect | Just-in-Time (JIT) | Just-in-Case (JIC) |

|---|---|---|

| Inventory Strategy | Minimum inventory, products made to order | High inventory, stockpiled for future demand |

| Risk Management | Low buffer, vulnerable to supply disruptions | High buffer, mitigates supply chain risks |

| Cost Focus | Reduces holding and storage costs | Increases holding and storage costs |

| Production Flexibility | Requires precise demand forecasting | Allows for unexpected demand spikes |

| Lead Time | Shorter lead times, fast replenishment | Longer lead times, slower replenishment |

| Supply Chain Dependency | High dependency on reliable suppliers | Less dependency due to stock reserves |

| Suitability | Best for stable demand environments | Best for uncertain or fluctuating demand |

Overview of Just-in-Time (JIT) and Just-in-Case (JIC) Strategies

Just-in-Time (JIT) manufacturing minimizes inventory by receiving materials only as they are needed in the production process, reducing storage costs and waste. Just-in-Case (JIC) strategy, in contrast, maintains large inventory buffers to safeguard against supply chain disruptions and demand fluctuations. Both approaches balance operational efficiency and risk management, with JIT prioritizing lean production and JIC emphasizing supply security.

Core Principles of JIT Manufacturing

Just-in-Time (JIT) manufacturing centers on reducing inventory levels by synchronizing production schedules precisely with demand, minimizing waste and operational costs. Core principles include continuous workflow, pull-based production control, and focused quality management to ensure each step adds value without excess stock. This approach relies on strong supplier relationships and rapid response systems to maintain lean operations and maximize efficiency.

Key Concepts of JIC Inventory Management

Just-in-Case (JIC) inventory management emphasizes maintaining large stock reserves to mitigate supply chain disruptions and demand fluctuations. Key concepts include buffer stock, safety stock levels, and risk management strategies to ensure continuous production flow despite uncertainties. This approach contrasts with Just-in-Time (JIT) by prioritizing inventory availability over lean operations, reducing the risk of stockouts at the expense of higher holding costs.

Benefits of Just-in-Time for Manufacturers

Just-in-Time (JIT) manufacturing reduces inventory holding costs and minimizes waste by synchronizing production schedules with demand, leading to improved cash flow and operational efficiency. This lean approach enhances responsiveness to market changes, enabling manufacturers to quickly adapt without excess stock. JIT systems also promote higher quality control through continuous monitoring and reduce lead times, driving overall competitive advantage.

Advantages of Just-in-Case in Risk Mitigation

Just-in-Case manufacturing enhances risk mitigation by maintaining strategic inventory buffers, ensuring production continuity amid supply chain disruptions. This approach reduces vulnerability to unexpected demand fluctuations, supplier delays, and geopolitical uncertainties. Firms employing Just-in-Case strategies achieve greater resilience and operational stability compared to leaner Just-in-Time systems.

Challenges in Implementing JIT Systems

Implementing Just-in-Time (JIT) systems presents challenges such as the need for highly reliable suppliers and seamless communication to prevent production delays. Manufacturing operations must maintain precise inventory control and demand forecasting to avoid stockouts and overproduction. Disruptions like supplier delays or sudden demand spikes can cause significant operational setbacks due to minimal buffer inventory in JIT environments.

Drawbacks of Relying on JIC Approaches

Relying on Just-in-Case (JIC) inventory strategies leads to increased holding costs, tying up capital in surplus stock that may become obsolete or deteriorate over time. Excessive inventory can mask inefficiencies in the supply chain, reducing responsiveness to market changes and increasing storage space requirements. These drawbacks make JIC less efficient compared to leaner, demand-driven methodologies like Just-in-Time (JIT) manufacturing.

Industry-Specific Applications of JIT and JIC

In manufacturing, Just-in-Time (JIT) is widely applied in automotive and electronics industries, where minimizing inventory reduces waste and enhances production efficiency. Just-in-Case (JIC) strategies are prevalent in pharmaceuticals and aerospace sectors, prioritizing inventory buffers to mitigate risks from supply chain disruptions. Industry-specific factors such as demand variability, lead times, and product complexity determine the optimal balance between JIT and JIC approaches.

Impact on Supply Chain Efficiency and Costs

Just-in-Time (JIT) manufacturing reduces inventory holding costs and enhances supply chain efficiency by minimizing excess stock and promoting lean production processes. In contrast, Just-in-Case (JIC) strategies increase operational costs due to higher inventory levels but provide a buffer against supply chain disruptions and demand variability. Companies adopting JIT benefit from improved cash flow and reduced waste, while JIC ensures supply continuity at the expense of capital tied up in inventory.

Choosing the Right Strategy: Factors for Decision-Making

Choosing between Just-in-Time (JIT) and Just-in-Case (JIC) manufacturing strategies depends heavily on factors such as market demand variability, supply chain reliability, and production lead times. Companies operating in stable markets with reliable suppliers often benefit from JIT by minimizing inventory costs and reducing waste, while those facing unpredictable demand or supply chain disruptions may prefer JIC to maintain buffer stock and avoid stockouts. Evaluating risk tolerance, cost implications, and customer service levels is essential to determine the most suitable approach for optimized operational efficiency.

Related Important Terms

Demand-Driven Replenishment

Demand-driven replenishment in manufacturing leverages Just-in-Time strategies to minimize inventory costs by aligning production schedules directly with real-time customer demand data. In contrast, Just-in-Case approaches maintain higher buffer stock levels to mitigate supply chain disruptions, prioritizing availability over efficiency.

Buffer Stock Optimization

Just-in-Time manufacturing minimizes inventory by synchronizing production with demand, reducing buffer stock to lower holding costs and increase efficiency. In contrast, Just-in-Case maintains higher buffer stock levels to safeguard against supply chain disruptions, prioritizing availability over cost savings.

Lean Inventory Flow

Just-in-Time inventory optimizes lean manufacturing by minimizing stock levels and reducing waste, ensuring materials arrive precisely when needed to maintain continuous production flow. In contrast, Just-in-Case inventory builds buffer stock to mitigate supply chain disruptions but increases holding costs and risks of obsolescence, impacting overall lean efficiency.

Agile Manufacturing Networks

Agile manufacturing networks leverage Just-in-Time (JIT) systems to minimize inventory costs and enhance responsiveness by synchronizing production with real-time demand signals. Conversely, Just-in-Case (JIC) strategies maintain buffer stock to mitigate supply chain disruptions, prioritizing resilience over lean efficiency within complex manufacturing ecosystems.

Kanban-Triggered Supply

Kanban-triggered supply optimizes Just-in-Time (JIT) manufacturing by signaling inventory replenishment only when downstream demand occurs, reducing waste and inventory costs. In contrast, Just-in-Case (JIC) relies on maintaining buffer stock to prevent production delays, often leading to higher holding costs and potential overstocking.

Risk-Pooled Warehousing

Risk-pooled warehousing in manufacturing strategically consolidates inventory to reduce overall stock levels, enhancing efficiency within Just-in-Time (JIT) systems by minimizing holding costs and improving responsiveness. In contrast, Just-in-Case (JIC) approaches maintain higher safety stock across multiple locations, increasing risk but safeguarding against supply chain disruptions and demand variability.

Dynamic Safety Stock

Dynamic safety stock adjusts inventory levels in real-time based on demand variability and supply chain disruptions, enhancing responsiveness in Just-in-Time manufacturing. In contrast, Just-in-Case relies on fixed safety stock buffers, leading to higher holding costs and less flexibility during unexpected changes.

Supply Chain Resilience Planning

Just-in-Time manufacturing minimizes inventory to reduce costs but increases vulnerability to supply chain disruptions, while Just-in-Case emphasizes holding extra stock to buffer against uncertainties, enhancing supply chain resilience. Effective supply chain resilience planning balances these strategies by integrating real-time data analytics and risk assessment tools to optimize inventory levels and ensure continuity.

Predictive Stock Levels

Predictive stock levels in Just-in-Time manufacturing minimize inventory costs by synchronizing supply with real-time demand forecasts, enhancing production efficiency. Just-in-Case approaches rely on higher safety stock based on historical variability and risk assessments to prevent disruptions from supply chain uncertainties.

Digital Twin Inventory

Digital Twin Inventory technology enhances Just-in-Time manufacturing by providing real-time simulation and predictive analytics to minimize stock levels and reduce waste. In contrast, it supports Just-in-Case strategies by enabling precise scenario planning and risk assessment, ensuring optimal inventory buffers without excessive capital lockup.

Just-in-Time vs Just-in-Case Infographic

industrydif.com

industrydif.com