Preventive maintenance schedules regular inspections and part replacements to minimize equipment downtime, ensuring consistent production efficiency. Condition-based monitoring uses real-time data from sensors to detect early signs of wear or failure, allowing precise intervention only when necessary. This approach reduces maintenance costs and extends machinery lifespan by addressing issues before they escalate.

Table of Comparison

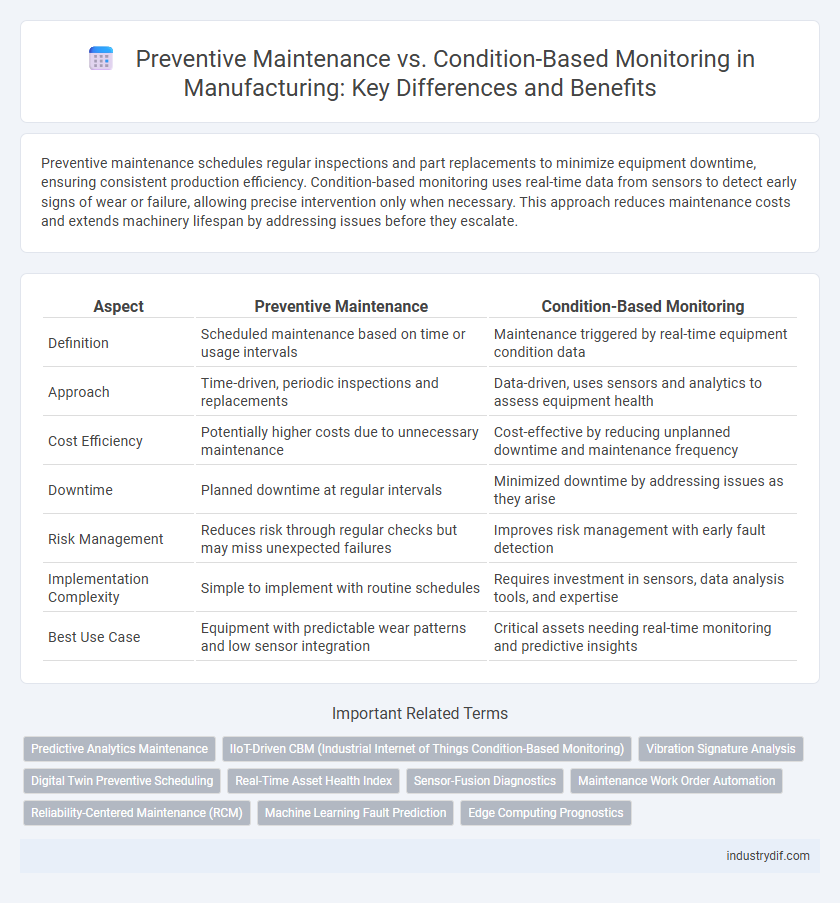

| Aspect | Preventive Maintenance | Condition-Based Monitoring |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals | Maintenance triggered by real-time equipment condition data |

| Approach | Time-driven, periodic inspections and replacements | Data-driven, uses sensors and analytics to assess equipment health |

| Cost Efficiency | Potentially higher costs due to unnecessary maintenance | Cost-effective by reducing unplanned downtime and maintenance frequency |

| Downtime | Planned downtime at regular intervals | Minimized downtime by addressing issues as they arise |

| Risk Management | Reduces risk through regular checks but may miss unexpected failures | Improves risk management with early fault detection |

| Implementation Complexity | Simple to implement with routine schedules | Requires investment in sensors, data analysis tools, and expertise |

| Best Use Case | Equipment with predictable wear patterns and low sensor integration | Critical assets needing real-time monitoring and predictive insights |

Introduction to Preventive Maintenance and Condition-Based Monitoring

Preventive Maintenance (PM) involves scheduled inspections and servicing of equipment to prevent unexpected failures and extend machinery life through routine tasks based on time or usage intervals. Condition-Based Monitoring (CBM) employs real-time data acquisition and analysis techniques, such as vibration analysis, thermography, and oil analysis, to assess equipment health and trigger maintenance only when specific indicators suggest degradation. Both approaches aim to optimize asset reliability but differ in execution; PM relies on fixed schedules, while CBM uses continuous monitoring to reduce downtime and maintenance costs.

Key Definitions: Preventive Maintenance Explained

Preventive maintenance involves scheduled inspections and part replacements based on time or usage intervals to reduce equipment failure and extend machinery life. This approach relies on historical data and manufacturer recommendations to preemptively address potential issues before symptoms arise. Effective preventive maintenance minimizes unexpected downtime and maintains consistent production quality.

What is Condition-Based Monitoring?

Condition-Based Monitoring (CBM) is an advanced maintenance strategy that uses real-time data from sensors to assess the actual condition of manufacturing equipment. By continuously tracking parameters such as vibration, temperature, and pressure, CBM enables early detection of potential failures, optimizing equipment lifespan and reducing downtime. Unlike scheduled Preventive Maintenance, CBM relies on data-driven insights to perform maintenance only when necessary, enhancing operational efficiency and cost-effectiveness.

Core Differences Between Preventive Maintenance and Condition-Based Monitoring

Preventive maintenance involves scheduled upkeep based on time or usage intervals to reduce equipment failure risk, whereas condition-based monitoring relies on real-time data and sensor diagnostics to perform maintenance only when indicators show deterioration. Preventive maintenance often results in higher labor and material costs due to routine servicing, while condition-based monitoring optimizes maintenance timing, minimizing downtime and extending asset lifespan. The core difference lies in preventive maintenance following a fixed schedule regardless of actual equipment condition, whereas condition-based monitoring depends on continuous assessment of machinery health for targeted interventions.

Advantages of Preventive Maintenance in Manufacturing

Preventive maintenance in manufacturing enhances equipment reliability by scheduling regular inspections and services, reducing unexpected breakdowns and costly downtime. This proactive approach extends machinery lifespan and improves production efficiency by ensuring consistent operational performance. It also facilitates better resource planning and inventory management, as maintenance activities are planned in advance based on time or usage intervals.

Benefits of Condition-Based Monitoring for Industrial Equipment

Condition-based monitoring enhances industrial equipment reliability by continuously tracking real-time data such as vibration, temperature, and pressure to detect early signs of wear or failure. This proactive approach reduces unplanned downtime and maintenance costs by enabling precise intervention only when necessary. Implementing condition-based monitoring extends equipment lifespan and optimizes operational efficiency compared to traditional preventive maintenance schedules.

Limitations of Preventive Maintenance Approaches

Preventive maintenance relies on fixed schedules that may not align with actual equipment wear, leading to unnecessary downtime or unexpected failures. This approach often overlooks real-time machine conditions, resulting in inefficiencies and increased maintenance costs. In contrast, condition-based monitoring offers more precise interventions by continuously tracking equipment health through sensors and data analytics.

Challenges with Condition-Based Monitoring Implementation

Condition-based monitoring (CBM) implementation in manufacturing faces challenges such as the high cost of advanced sensor installation and integration with existing systems, which can strain operational budgets. Data management complexity arises from continuous real-time monitoring, requiring sophisticated analytics and skilled personnel to interpret sensor outputs accurately. Ensuring sensor reliability and dealing with environmental noise can lead to false alarms or missed detections, impacting maintenance decision quality.

Integration Strategies: Combining Preventive Maintenance and Condition-Based Monitoring

Integrating preventive maintenance with condition-based monitoring enhances manufacturing efficiency by leveraging scheduled inspections alongside real-time equipment data to predict failures accurately. This hybrid strategy reduces unplanned downtime and extends asset lifespan through timely interventions based on actual machine conditions. Advanced analytics platforms facilitate seamless data fusion, enabling optimized maintenance schedules that balance cost-efficiency with operational reliability.

Future Trends in Maintenance Practices for the Manufacturing Industry

Future trends in manufacturing maintenance emphasize the integration of AI-powered predictive analytics with condition-based monitoring to enhance equipment reliability and reduce unplanned downtime. Advanced IoT sensors continuously collect real-time machine data, enabling precise condition assessments and facilitating transition from time-based preventive maintenance to more efficient, data-driven strategies. Digital twins and machine learning algorithms are becoming essential tools for optimizing maintenance schedules, increasing asset lifespan, and lowering operational costs across smart factories.

Related Important Terms

Predictive Analytics Maintenance

Predictive analytics maintenance leverages data from condition-based monitoring systems to forecast equipment failures, enabling manufacturers to perform targeted preventive maintenance before costly breakdowns occur. By integrating machine learning algorithms with real-time sensor data, predictive maintenance improves asset utilization, reduces downtime, and lowers overall maintenance costs compared to traditional time-based preventive strategies.

IIoT-Driven CBM (Industrial Internet of Things Condition-Based Monitoring)

IIoT-driven Condition-Based Monitoring leverages real-time sensor data and advanced analytics to predict equipment failures and optimize maintenance schedules, significantly reducing downtime compared to traditional preventive maintenance methods. By continuously monitoring machine health through interconnected devices, manufacturers achieve higher asset utilization, lower operational costs, and enhanced production efficiency.

Vibration Signature Analysis

Vibration Signature Analysis enhances Preventive Maintenance by detecting equipment anomalies before failure, enabling targeted repairs that reduce downtime and extend machinery lifespan. Condition-Based Monitoring leverages real-time vibration data to optimize maintenance schedules, improving reliability and operational efficiency in manufacturing environments.

Digital Twin Preventive Scheduling

Digital Twin Preventive Scheduling integrates real-time data and predictive analytics to enhance preventive maintenance by simulating equipment behavior and forecasting failures before they occur. This approach optimizes maintenance intervals, reduces downtime, and extends asset lifespan compared to traditional condition-based monitoring that relies solely on sensor data thresholds.

Real-Time Asset Health Index

Real-time Asset Health Index enhances preventive maintenance by providing continuous, data-driven insights into equipment conditions, enabling timely interventions before failures occur. Condition-based monitoring leverages sensors and analytics to track asset performance in real-time, optimizing maintenance schedules and reducing downtime.

Sensor-Fusion Diagnostics

Sensor-fusion diagnostics integrates data from multiple sensor types to enhance the accuracy and reliability of condition-based monitoring, enabling real-time detection of equipment anomalies before failures occur. This approach surpasses traditional preventive maintenance by reducing unplanned downtime and optimizing maintenance schedules through predictive insights derived from comprehensive sensor data analysis.

Maintenance Work Order Automation

Preventive maintenance schedules routine tasks to prevent equipment failure, optimizing maintenance work order automation by enabling predictable resource allocation and minimizing downtime. Condition-based monitoring automates work orders by using real-time sensor data and analytics, triggering maintenance only when specific equipment conditions indicate potential issues, enhancing operational efficiency and reducing unnecessary interventions.

Reliability-Centered Maintenance (RCM)

Reliability-Centered Maintenance (RCM) integrates Preventive Maintenance and Condition-Based Monitoring by prioritizing asset reliability through tailored maintenance strategies based on equipment criticality and failure modes. This approach enhances operational efficiency by utilizing real-time condition data to predict failures while maintaining scheduled upkeep to extend machinery lifespan and reduce downtime.

Machine Learning Fault Prediction

Machine learning fault prediction leverages condition-based monitoring data to identify early signs of equipment failure, enabling more accurate and timely interventions compared to traditional preventive maintenance schedules. This approach reduces unplanned downtime and maintenance costs by analyzing real-time sensor data to predict faults before they cause significant machine damage.

Edge Computing Prognostics

Edge computing prognostics enhances condition-based monitoring by processing real-time sensor data onsite, enabling precise predictions of equipment failures and reducing downtime. Preventive maintenance schedules often rely on fixed intervals, whereas edge-driven condition monitoring adapts dynamically to actual machine health, optimizing resource allocation and extending asset lifespan.

Preventive Maintenance vs Condition-Based Monitoring Infographic

industrydif.com

industrydif.com