Supply Chain Management (SCM) focuses on optimizing the flow of materials, information, and finances from suppliers to end consumers, emphasizing cost efficiency and timely delivery. Circular Supply Chain integrates principles of sustainability by designing processes that prioritize reuse, recycling, and minimizing waste, creating closed-loop systems that reduce environmental impact. The shift from traditional SCM to Circular Supply Chain enhances resource efficiency and fosters long-term resilience in manufacturing operations.

Table of Comparison

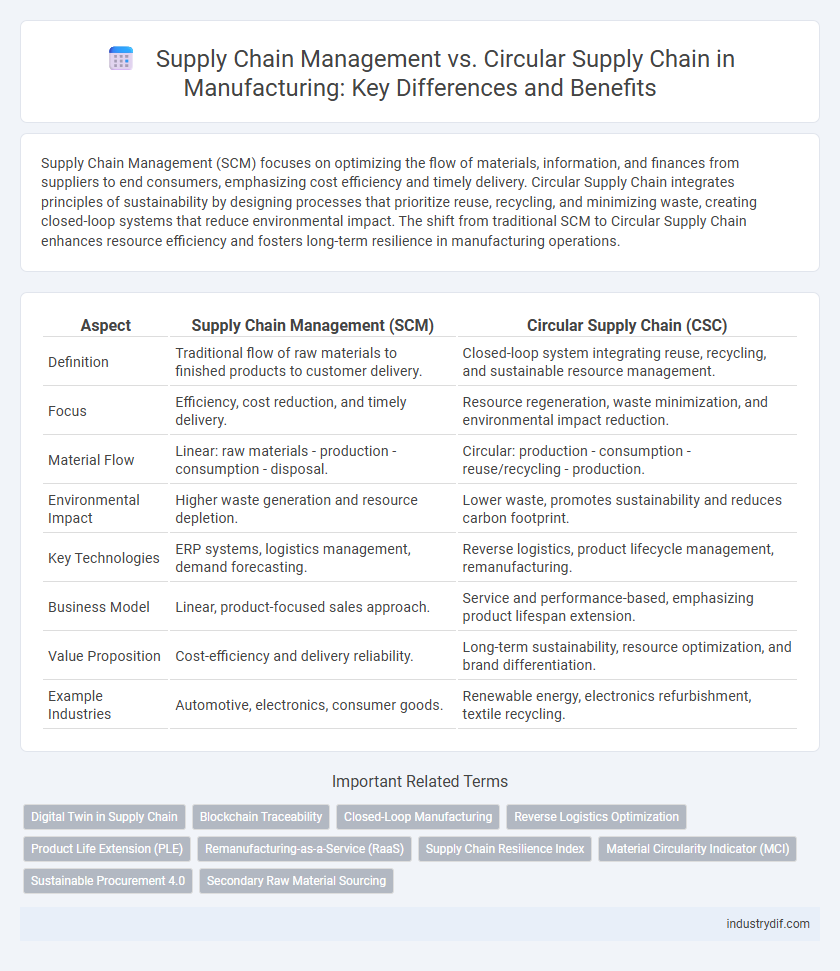

| Aspect | Supply Chain Management (SCM) | Circular Supply Chain (CSC) |

|---|---|---|

| Definition | Traditional flow of raw materials to finished products to customer delivery. | Closed-loop system integrating reuse, recycling, and sustainable resource management. |

| Focus | Efficiency, cost reduction, and timely delivery. | Resource regeneration, waste minimization, and environmental impact reduction. |

| Material Flow | Linear: raw materials - production - consumption - disposal. | Circular: production - consumption - reuse/recycling - production. |

| Environmental Impact | Higher waste generation and resource depletion. | Lower waste, promotes sustainability and reduces carbon footprint. |

| Key Technologies | ERP systems, logistics management, demand forecasting. | Reverse logistics, product lifecycle management, remanufacturing. |

| Business Model | Linear, product-focused sales approach. | Service and performance-based, emphasizing product lifespan extension. |

| Value Proposition | Cost-efficiency and delivery reliability. | Long-term sustainability, resource optimization, and brand differentiation. |

| Example Industries | Automotive, electronics, consumer goods. | Renewable energy, electronics refurbishment, textile recycling. |

Introduction to Traditional Supply Chain Management

Traditional Supply Chain Management (SCM) focuses on the linear flow of materials, information, and finances from suppliers to manufacturers, distributors, and end customers, emphasizing cost efficiency and timely delivery. It primarily prioritizes demand forecasting, inventory control, and supplier coordination to optimize production schedules and reduce operational expenses. However, this approach often leads to significant waste and limited resource recovery, contrasting with the principles of Circular Supply Chain models.

Defining Circular Supply Chain Concepts

Circular Supply Chain integrates principles of reuse, recycling, and resource regeneration into traditional Supply Chain Management, focusing on minimizing waste and environmental impact. Unlike linear Supply Chains that rely on a take-make-dispose model, Circular Supply Chains emphasize closed-loop processes, extending product life cycles through remanufacturing and refurbishment. This approach leverages sustainable sourcing, reverse logistics, and lifecycle assessments to optimize resource efficiency and support a circular economy in manufacturing.

Key Differences: Linear vs Circular Supply Chains

Linear supply chains follow a straightforward progression from raw material extraction to production, distribution, and disposal, emphasizing one-way flow and resource consumption. Circular supply chains prioritize resource recovery, reuse, and recycling, creating closed-loop systems that minimize waste and environmental impact. The key difference lies in the sustainability focus, with circular supply chains integrating regenerative practices to extend product life cycles and reduce reliance on finite resources.

Environmental Impact: Traditional vs Circular Approaches

Traditional supply chain management typically prioritizes efficiency and cost reduction, often resulting in significant waste generation and resource depletion. Circular supply chains emphasize resource recovery, recycling, and product lifecycle extension, significantly reducing environmental impact through waste minimization and lower carbon emissions. By integrating circular principles, manufacturers can enhance sustainability, decrease landfill contributions, and mitigate climate change effects tied to linear production models.

Cost Implications in Linear and Circular Supply Chains

Supply chain management in traditional linear models typically incurs higher costs due to resource extraction, waste disposal, and inefficiencies in production and logistics, leading to increased operational expenses. Circular supply chains reduce costs by promoting resource reuse, recycling, and remanufacturing, which lowers raw material inputs and waste management expenses while enhancing long-term sustainability. Companies adopting circular supply chain strategies benefit from reduced procurement costs and improved cost predictability through closed-loop processes and efficient material recovery.

Resource Efficiency and Waste Reduction

Supply Chain Management optimizes resource allocation and reduces waste through streamlined procurement and logistics processes. Circular Supply Chain integrates product lifecycle design and reverse logistics to maximize resource efficiency by reusing, remanufacturing, and recycling materials. This closed-loop system significantly lowers environmental impact and promotes sustainable manufacturing practices.

Technology’s Role in Circular Supply Chains

Technology enhances circular supply chains by enabling real-time tracking, predictive analytics, and resource optimization, reducing waste and improving sustainability in manufacturing. Advanced IoT devices and blockchain improve transparency and traceability, ensuring materials are reused and recycled efficiently. Digital platforms facilitate collaboration among stakeholders, supporting closed-loop processes and driving circular economy goals within supply chain management.

Challenges and Barriers to Circular Supply Chain Adoption

Supply Chain Management faces significant challenges in transitioning to Circular Supply Chain models, including complex reverse logistics, high initial investment costs, and difficulties in tracking and recovering materials. Barriers to Circular Supply Chain adoption also involve limited supplier collaboration, inadequate infrastructure for recycling and remanufacturing, and regulatory constraints that hinder circular processes. Overcoming these obstacles requires advancements in digital technologies, enhanced transparency, and supportive policies to enable efficient resource circulation and reduce waste in manufacturing systems.

Case Studies: Circular Supply Chain Success Stories

Case studies reveal that circular supply chain models in manufacturing reduce waste and enhance resource efficiency by reusing materials and extending product lifecycles, exemplified by companies like Philips and IKEA. Philips achieved substantial cost savings and environmental impact reduction through its circular economy initiatives in electronics, while IKEA's furniture take-back and recycling program strengthens supply chain sustainability. These success stories highlight the economic and ecological benefits of integrating circular principles into traditional supply chain management.

Future Trends in Supply Chain Management

Future trends in supply chain management emphasize digital integration, artificial intelligence, and sustainability to enhance efficiency and resilience. Circular supply chains prioritize resource recovery, waste reduction, and product lifecycle extension to support environmental goals and regulatory compliance. Innovations in blockchain and IoT enable transparency and traceability, driving the transformation from traditional to circular supply chain models in manufacturing.

Related Important Terms

Digital Twin in Supply Chain

Digital Twin technology revolutionizes Supply Chain Management by creating virtual replicas of physical supply chains, enabling real-time monitoring, predictive analytics, and optimized decision-making. In Circular Supply Chains, Digital Twins enhance resource efficiency and waste reduction by simulating product lifecycle scenarios, facilitating sustainable practices and closed-loop processes.

Blockchain Traceability

Blockchain traceability in supply chain management enhances transparency and accountability by providing immutable records of product origins and movements, optimizing traditional linear workflows. In circular supply chains, blockchain facilitates the tracking of recycled materials and product life cycles, enabling efficient resource recovery and promoting sustainable manufacturing practices.

Closed-Loop Manufacturing

Closed-loop manufacturing integrates circular supply chain principles to minimize waste by reusing materials and components throughout production cycles, enhancing sustainability and resource efficiency. Supply chain management traditionally prioritizes cost and efficiency, whereas circular supply chain strategies emphasize product life extension, recycling, and regeneration within closed-loop systems.

Reverse Logistics Optimization

Reverse logistics optimization in Circular Supply Chain Management focuses on efficiently reclaiming, refurbishing, and recycling materials to minimize waste and reduce costs, unlike traditional Supply Chain Management that primarily emphasizes forward flow of goods. Enhanced visibility, real-time tracking, and automation in circular supply chains enable manufacturers to streamline returns and reintegrate resources, driving sustainability and operational resilience.

Product Life Extension (PLE)

Supply Chain Management (SCM) traditionally focuses on optimizing production and distribution efficiency, while Circular Supply Chain (CSC) emphasizes Product Life Extension (PLE) through reuse, refurbishment, and recycling to minimize waste and resource consumption. Implementing PLE strategies in CSC enhances sustainability by prolonging product usability, reducing raw material demand, and lowering environmental impact compared to linear SCM models.

Remanufacturing-as-a-Service (RaaS)

Supply Chain Management traditionally emphasizes the flow of raw materials and finished goods through linear processes, while Circular Supply Chain integrates Remanufacturing-as-a-Service (RaaS) to extend product life cycles by refurbishing and reintroducing used components, reducing waste and minimizing resource consumption. RaaS enables manufacturers to leverage digital platforms and IoT technologies for efficient asset tracking, predictive maintenance, and on-demand remanufacturing, fostering sustainability and cost savings within circular economy frameworks.

Supply Chain Resilience Index

The Supply Chain Resilience Index measures the ability to anticipate, absorb, and recover from disruptions, revealing that traditional Supply Chain Management often focuses on efficiency and cost reduction, whereas Circular Supply Chains emphasize sustainability and resource regeneration to enhance long-term resilience. Incorporating circular principles into supply chains significantly improves resilience by minimizing dependency on virgin materials and promoting closed-loop processes that mitigate supply shocks.

Material Circularity Indicator (MCI)

Supply Chain Management traditionally focuses on optimizing cost, efficiency, and delivery times, whereas Circular Supply Chain prioritizes resource reuse, waste reduction, and sustainability, measured by the Material Circularity Indicator (MCI), which quantifies the proportion of recycled and renewable materials in products. High MCI scores correlate with improved environmental performance and resilient supply chains by minimizing virgin material dependency and promoting closed-loop systems.

Sustainable Procurement 4.0

Supply Chain Management integrates digital technologies to optimize resource allocation and reduce costs, while Circular Supply Chain emphasizes sustainable procurement 4.0 by prioritizing renewable materials, waste minimization, and closed-loop systems for environmental impact reduction. Sustainable Procurement 4.0 leverages AI, IoT, and blockchain to enhance transparency, supplier collaboration, and lifecycle assessment in both traditional and circular supply networks.

Secondary Raw Material Sourcing

Supply Chain Management traditionally prioritizes primary raw material sourcing to optimize cost and efficiency, whereas Circular Supply Chain emphasizes secondary raw material sourcing by reclaiming and reprocessing waste to reduce environmental impact and resource dependency. Incorporating secondary raw materials in manufacturing promotes sustainability, lowers material costs, and supports closed-loop systems vital for circular economy practices.

Supply Chain Management vs Circular Supply Chain Infographic

industrydif.com

industrydif.com