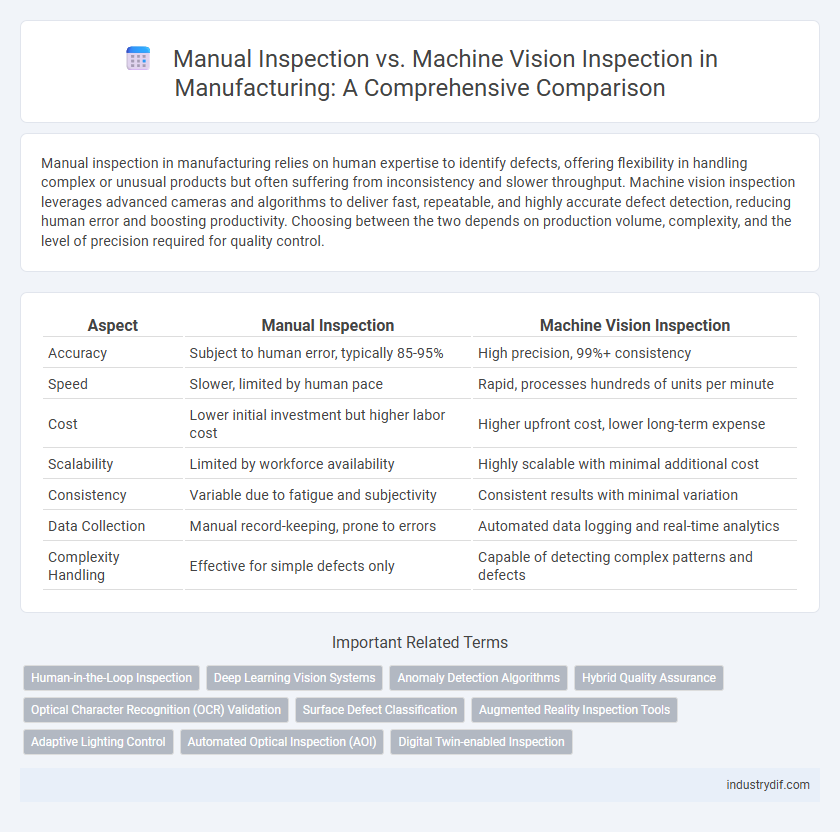

Manual inspection in manufacturing relies on human expertise to identify defects, offering flexibility in handling complex or unusual products but often suffering from inconsistency and slower throughput. Machine vision inspection leverages advanced cameras and algorithms to deliver fast, repeatable, and highly accurate defect detection, reducing human error and boosting productivity. Choosing between the two depends on production volume, complexity, and the level of precision required for quality control.

Table of Comparison

| Aspect | Manual Inspection | Machine Vision Inspection |

|---|---|---|

| Accuracy | Subject to human error, typically 85-95% | High precision, 99%+ consistency |

| Speed | Slower, limited by human pace | Rapid, processes hundreds of units per minute |

| Cost | Lower initial investment but higher labor cost | Higher upfront cost, lower long-term expense |

| Scalability | Limited by workforce availability | Highly scalable with minimal additional cost |

| Consistency | Variable due to fatigue and subjectivity | Consistent results with minimal variation |

| Data Collection | Manual record-keeping, prone to errors | Automated data logging and real-time analytics |

| Complexity Handling | Effective for simple defects only | Capable of detecting complex patterns and defects |

Introduction to Inspection Methods in Manufacturing

Manual inspection in manufacturing relies on human operators to visually examine products for defects, ensuring quality control through direct observation and tactile evaluation. Machine vision inspection utilizes advanced cameras and artificial intelligence algorithms to rapidly detect inconsistencies, enhancing accuracy and consistency in identifying defects across high-volume production lines. Combining both methods enables manufacturers to balance flexibility and precision, optimizing defect detection and improving overall product quality.

Defining Manual Inspection

Manual inspection in manufacturing involves human operators visually examining products to identify defects or inconsistencies, relying on experience and judgment. This method is typically time-consuming and subject to variability due to fatigue and human error, impacting consistency and throughput. Despite limitations, manual inspection remains crucial for detecting subtle or complex defects that automated systems may miss.

Explaining Machine Vision Inspection

Machine vision inspection uses cameras and image processing software to automatically detect defects, measure components, and verify assembly quality with high precision and speed. This technology integrates advanced algorithms and artificial intelligence to analyze visual data in real-time, reducing human error and increasing inspection consistency across production lines. Machine vision systems enhance manufacturing efficiency by enabling rapid, non-contact inspection suitable for high-volume and complex products.

Accuracy Comparison: Manual vs Machine Vision

Machine vision inspection systems deliver higher accuracy than manual inspection by leveraging advanced image processing algorithms and consistent lighting conditions that reduce human error and variability. Manual inspection accuracy is limited by human factors such as fatigue, inconsistent judgment, and slower processing speeds, often resulting in missed defects or false positives. Studies show machine vision systems can achieve defect detection rates above 99%, outperforming manual inspection accuracy, which typically ranges between 70-85% depending on operator skill and environmental conditions.

Speed and Efficiency in Inspection Processes

Manual inspection relies heavily on human labor, resulting in slower throughput and higher variability in speed and accuracy. Machine vision inspection systems leverage high-speed cameras and AI algorithms to rapidly analyze products, significantly increasing inspection speed and consistency. The integration of machine vision reduces bottlenecks and enhances overall manufacturing efficiency by enabling real-time quality control.

Human Error vs Automated Consistency

Manual inspection in manufacturing often suffers from human error, leading to inconsistencies and variable quality outcomes. Machine vision inspection systems deliver automated consistency through high-precision cameras and AI algorithms, significantly reducing defects and increasing throughput. The integration of automated inspection enhances reliability by minimizing subjective judgment and fatigue-related mistakes inherent in manual processes.

Cost Implications of Each Method

Manual inspection involves higher labor costs due to reliance on skilled operators and increased inspection time, leading to greater overall expenses in large-scale manufacturing. Machine vision inspection requires upfront investment in advanced camera systems and software but significantly reduces per-unit inspection costs through automation and faster processing. Over time, machine vision offers better cost efficiency by minimizing human error and lowering operational expenses compared to manual methods.

Applications Suitable for Manual and Machine Vision

Manual inspection excels in applications requiring intricate visual judgment, such as identifying subtle surface defects or color variations on small batches and complex assemblies. Machine vision inspection is ideal for high-speed, high-volume production lines demanding consistent precision and real-time data processing, including electronics manufacturing and automotive parts inspection. Selecting the optimal approach depends on factors like inspection speed, complexity, repeatability, and cost efficiency.

Integration with Manufacturing Systems

Manual inspection offers flexibility but lacks seamless integration with automated manufacturing execution systems (MES), leading to slower data collection and potential errors. Machine vision inspection integrates directly with MES and programmable logic controllers (PLCs), enabling real-time quality monitoring and immediate feedback for process adjustments. This integration enhances traceability, reduces downtime, and supports data-driven decision-making in smart manufacturing environments.

Future Trends in Inspection Technology

Future trends in manufacturing inspection technology emphasize the integration of artificial intelligence with machine vision systems to enhance defect detection accuracy and speed. Advanced machine learning algorithms enable real-time analysis of complex data patterns, reducing reliance on manual inspection and minimizing human error. The adoption of smart cameras and IoT connectivity promotes continuous process monitoring and predictive maintenance, driving higher efficiency and quality control.

Related Important Terms

Human-in-the-Loop Inspection

Human-in-the-Loop Inspection combines the precision of machine vision systems with expert human judgment to enhance defect detection and reduce false positives in manufacturing quality control. Integrating manual inspection with automated vision technology increases accuracy, accelerates decision-making, and improves overall production efficiency by leveraging human expertise for complex or ambiguous visual assessments.

Deep Learning Vision Systems

Deep learning vision systems enhance machine vision inspection by accurately identifying defects through advanced neural networks and real-time image processing, outperforming manual inspection in consistency and speed. These systems reduce human error and increase production efficiency by leveraging large datasets and adaptive algorithms to detect subtle anomalies in complex manufacturing environments.

Anomaly Detection Algorithms

Anomaly detection algorithms in machine vision inspection leverage advanced pattern recognition and machine learning techniques to identify defects with higher accuracy and speed compared to manual inspection. These algorithms analyze large datasets in real time, reducing human error and enabling consistent quality control in manufacturing processes.

Hybrid Quality Assurance

Hybrid quality assurance in manufacturing combines manual inspection's adaptability with machine vision inspection's precision, resulting in enhanced defect detection and reduced error rates. Integrating human expertise and AI-powered image analysis optimizes quality control processes, improving accuracy, speed, and overall product reliability.

Optical Character Recognition (OCR) Validation

Manual inspection in manufacturing relies on human operators to visually verify product details, which can lead to inconsistencies and slower throughput during Optical Character Recognition (OCR) validation. Machine vision inspection systems equipped with advanced OCR algorithms provide faster, more accurate validation of printed codes and labels, reducing errors and increasing production efficiency.

Surface Defect Classification

Manual inspection relies heavily on human expertise to identify and classify surface defects, offering flexibility but limited consistency and speed in high-volume production. Machine vision inspection employs advanced image processing algorithms and artificial intelligence to accurately detect and categorize surface anomalies, enhancing throughput and reducing error rates.

Augmented Reality Inspection Tools

Augmented reality inspection tools integrate machine vision inspection technology to enhance accuracy and speed in manufacturing quality control, enabling real-time defect detection and operator guidance. These tools reduce human error associated with manual inspection and improve efficiency by overlaying digital information directly onto physical products during the inspection process.

Adaptive Lighting Control

Adaptive lighting control in machine vision inspection significantly enhances defect detection accuracy by dynamically adjusting illumination based on surface characteristics, outperforming manual inspection's static lighting conditions. This technology reduces inspection variability and increases throughput, ensuring consistent quality control across complex manufacturing processes.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) systems significantly enhance defect detection accuracy and speed compared to manual inspection by utilizing high-resolution cameras and advanced image processing algorithms to identify surface defects, misalignments, and component absence in manufacturing lines. Implementing AOI reduces human error, increases production throughput, and ensures consistent quality control in electronics and semiconductor manufacturing processes.

Digital Twin-enabled Inspection

Digital Twin-enabled inspection leverages real-time data integration and predictive analytics to enhance accuracy and efficiency beyond traditional manual inspection and conventional machine vision systems. This technology creates a virtual replica of physical assets, enabling continuous monitoring, defect detection, and process optimization within manufacturing environments.

Manual Inspection vs Machine Vision Inspection Infographic

industrydif.com

industrydif.com