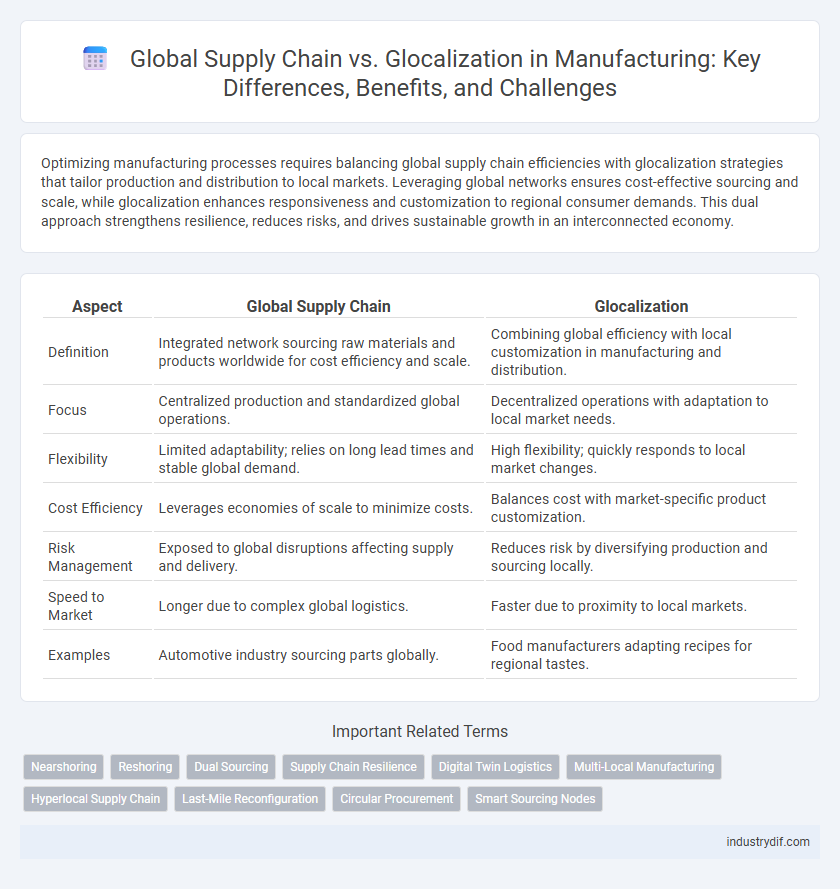

Optimizing manufacturing processes requires balancing global supply chain efficiencies with glocalization strategies that tailor production and distribution to local markets. Leveraging global networks ensures cost-effective sourcing and scale, while glocalization enhances responsiveness and customization to regional consumer demands. This dual approach strengthens resilience, reduces risks, and drives sustainable growth in an interconnected economy.

Table of Comparison

| Aspect | Global Supply Chain | Glocalization |

|---|---|---|

| Definition | Integrated network sourcing raw materials and products worldwide for cost efficiency and scale. | Combining global efficiency with local customization in manufacturing and distribution. |

| Focus | Centralized production and standardized global operations. | Decentralized operations with adaptation to local market needs. |

| Flexibility | Limited adaptability; relies on long lead times and stable global demand. | High flexibility; quickly responds to local market changes. |

| Cost Efficiency | Leverages economies of scale to minimize costs. | Balances cost with market-specific product customization. |

| Risk Management | Exposed to global disruptions affecting supply and delivery. | Reduces risk by diversifying production and sourcing locally. |

| Speed to Market | Longer due to complex global logistics. | Faster due to proximity to local markets. |

| Examples | Automotive industry sourcing parts globally. | Food manufacturers adapting recipes for regional tastes. |

Defining Global Supply Chain in Manufacturing

A global supply chain in manufacturing integrates suppliers, production facilities, and distribution networks across multiple countries to optimize cost efficiency and resource access. It relies on real-time data analytics and logistics coordination to balance inventory levels and mitigate risks from geopolitical disruptions. Emphasizing scalability, this system leverages advanced technologies such as IoT and AI to enhance supply visibility and responsiveness in diverse international markets.

Understanding Glocalization in Industry

Glocalization in manufacturing integrates global supply chain efficiencies with localized production strategies to enhance responsiveness to regional market demands and regulatory environments. By adapting products and processes to fit local cultures and consumer preferences, companies reduce lead times and logistics costs while improving customer satisfaction. This approach balances standardization and customization, enabling manufacturers to optimize resources and maintain competitive advantage in diverse markets.

Key Differences: Global vs. Glocal Supply Chains

Global supply chains emphasize centralized production and standardized products across international markets, optimizing cost efficiency and scalability. Glocal supply chains integrate global efficiency with local responsiveness by adapting products and operations to regional preferences and regulations. Key differences include the level of customization, inventory management strategies, and the balance between global coordination versus local autonomy.

Impact of Globalization on Manufacturing Operations

Globalization has streamlined manufacturing operations by integrating supply chains across borders, enabling access to diverse resources and cost efficiencies. The trend toward glocalization tailors global manufacturing strategies to local markets, enhancing responsiveness to regional demands while maintaining overall scale advantages. These approaches collectively optimize production flexibility, reduce lead times, and support sustainable growth within complex international networks.

Benefits of Glocalization for Local Industries

Glocalization enhances local industries by integrating global resources with regional knowledge, enabling manufacturing processes to adapt to local market demands efficiently. This approach reduces transportation costs and lead times, improving supply chain responsiveness and minimizing disruptions. Localized decision-making fosters innovation tailored to cultural preferences, boosting competitiveness in both domestic and international markets.

Challenges of Managing Global Supply Chains

Global supply chains face challenges such as geopolitical risks, fluctuating trade policies, and complex logistics that disrupt timely delivery and increase operational costs. Managing diverse regulatory requirements and cultural differences across countries complicates coordination and communication among suppliers and partners. Companies implementing glocalization strategies struggle to balance global standardization with local customization, intensifying supply chain complexity and affecting scalability.

Glocalization Strategies for Competitive Advantage

Glocalization strategies in manufacturing enhance competitive advantage by tailoring global supply chain processes to local market needs, improving responsiveness and reducing lead times. Adapting product designs, procurement, and production methods to regional preferences increases customer satisfaction and operational efficiency. Integrating local suppliers and leveraging regional talent pools supports flexibility and innovation within global networks, fostering sustainable growth.

Supply Chain Risk Management: Global vs. Glocal

Global supply chain risk management faces challenges including geopolitical instability, longer lead times, and increased exposure to disruptions across multiple regions. In contrast, glocalization strategies prioritize localized sourcing and production, reducing vulnerability by shortening supply routes and enhancing responsiveness to regional market demands. Emphasizing glocal supply chain models improves resilience through diversification and adaptive capabilities, mitigating risks inherent in global dependencies.

Technology’s Role in Global and Glocal Supply Chains

Technology integrates global supply chains by enabling real-time data sharing, advanced analytics, and automated processes, which enhance efficiency and transparency across international operations. In glocal supply chains, technology facilitates adaptability by supporting localized production adjustments, supply flexibility, and customer-specific customization through digital platforms and IoT connectivity. Advanced technologies like AI, blockchain, and cloud computing provide critical tools for both global coordination and local responsiveness, driving resilience and competitive advantage in manufacturing ecosystems.

Future Trends: Balancing Global and Glocal Approaches

Future trends in manufacturing emphasize harmonizing global supply chain efficiency with glocalization strategies to enhance responsiveness and sustainability. Integrating advanced technologies like AI and IoT allows real-time adaptation to local market demands while maintaining global scale benefits. This balanced approach reduces risks from geopolitical disruptions and optimizes resource allocation across regional manufacturing hubs.

Related Important Terms

Nearshoring

Nearshoring enhances global supply chains by relocating manufacturing closer to end markets, reducing lead times and transportation costs while improving responsiveness to local demand variations. This strategy supports glocalization by blending global operational scale with local market adaptation, increasing supply chain resilience amid geopolitical uncertainties and fluctuating trade policies.

Reshoring

Reshoring in manufacturing addresses global supply chain vulnerabilities by relocating production closer to end markets, enhancing responsiveness and reducing transportation costs. Glocalization integrates local market adaptation with global efficiencies, balancing centralized control and regional customization to optimize supply chain resilience.

Dual Sourcing

Dual sourcing in manufacturing leverages both global supply chains and glocalization strategies by integrating international suppliers with local production partners to mitigate risks and optimize cost-efficiency. This approach enhances supply chain resilience, ensuring continuous material flow while adapting to regional market demands and regulatory requirements.

Supply Chain Resilience

Global supply chain strategies offer cost efficiency and scale but face vulnerabilities from geopolitical disruptions and pandemics, highlighting the necessity for glocalization to enhance supply chain resilience. Glocalization integrates local sourcing and manufacturing with global networks, reducing dependency risks and improving responsiveness to regional market fluctuations.

Digital Twin Logistics

Digital twin logistics enhances global supply chain efficiency by creating real-time virtual replicas of physical assets, enabling predictive analytics and seamless coordination across international networks. Integrating glocalization strategies with digital twin technology allows manufacturers to tailor logistics operations to local market conditions while maintaining global supply chain agility and resilience.

Multi-Local Manufacturing

Multi-local manufacturing enhances global supply chain resilience by decentralizing production across multiple regional hubs, minimizing risks from geopolitical tensions and transportation disruptions. This approach supports glocalization strategies by enabling manufacturers to customize products to local market demands while maintaining cost efficiency and agility.

Hyperlocal Supply Chain

Hyperlocal supply chains enhance manufacturing agility by sourcing materials within a limited geographic area, reducing lead times and transportation costs while improving responsiveness to local market demands. Unlike global supply chains that prioritize cost efficiency through widespread sourcing, hyperlocal strategies emphasize proximity, sustainability, and customization, enabling manufacturers to adapt swiftly to regional variations and disruptions.

Last-Mile Reconfiguration

Last-mile reconfiguration in manufacturing supply chains enhances efficiency by integrating global sourcing with glocalization strategies, optimizing delivery times and reducing costs through localized distribution hubs. This approach leverages advanced data analytics and flexible logistics networks to balance global scale advantages with local market responsiveness, improving overall supply chain resilience.

Circular Procurement

Global supply chains emphasize efficiency and scale but often face challenges in sustainability and local responsiveness, whereas glocalization integrates global reach with local adaptation, enhancing circular procurement by promoting resource reuse and minimizing waste within regional markets. Circular procurement under glocalization leverages localized supplier networks to reduce transportation emissions and supports closed-loop systems that optimize material recovery, driving sustainable manufacturing across diverse geographies.

Smart Sourcing Nodes

Smart sourcing nodes enhance global supply chain efficiency by localizing key manufacturing and procurement processes to reduce lead times and costs. Leveraging real-time data analytics and IoT integration, these nodes enable manufacturers to adapt quickly to regional market demands while maintaining global operational standards.

Global Supply Chain vs Glocalization Infographic

industrydif.com

industrydif.com