Just-In-Time (JIT) manufacturing emphasizes minimizing inventory and reducing waste by producing goods only as they are needed, enhancing efficiency and lowering costs. Smart manufacturing integrates advanced technologies such as IoT, AI, and data analytics to optimize production processes, improve quality, and enable real-time decision-making. Combining JIT principles with smart manufacturing solutions enables dynamic, responsive operations that adapt swiftly to market demands while maintaining lean workflows.

Table of Comparison

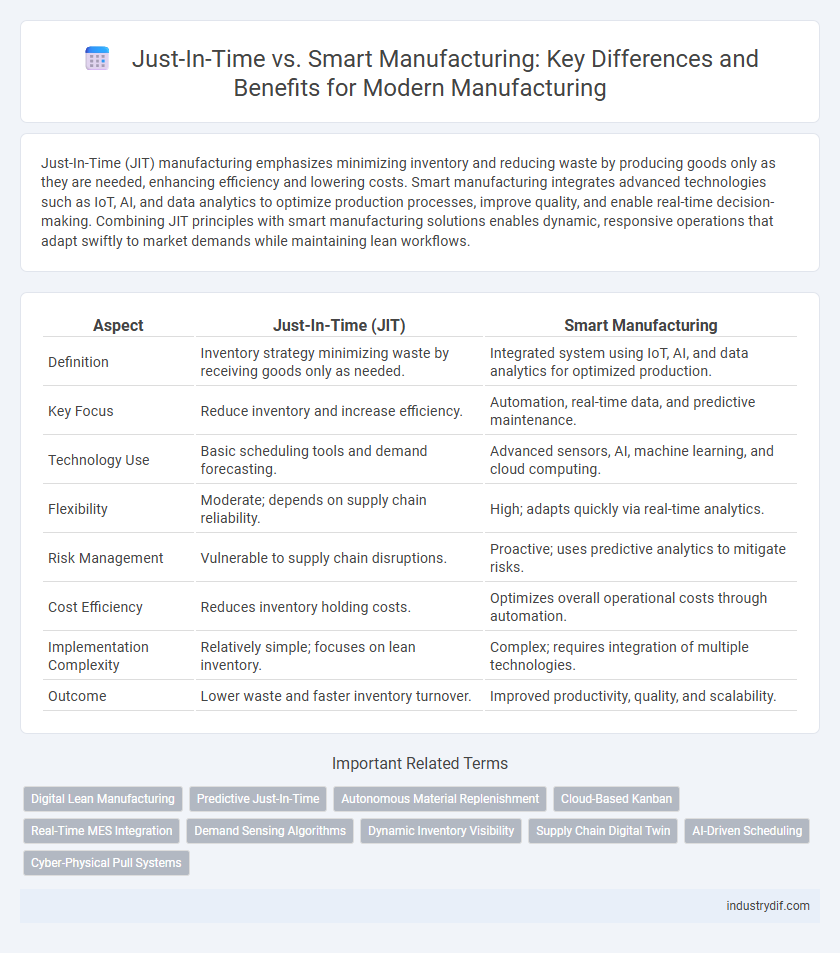

| Aspect | Just-In-Time (JIT) | Smart Manufacturing |

|---|---|---|

| Definition | Inventory strategy minimizing waste by receiving goods only as needed. | Integrated system using IoT, AI, and data analytics for optimized production. |

| Key Focus | Reduce inventory and increase efficiency. | Automation, real-time data, and predictive maintenance. |

| Technology Use | Basic scheduling tools and demand forecasting. | Advanced sensors, AI, machine learning, and cloud computing. |

| Flexibility | Moderate; depends on supply chain reliability. | High; adapts quickly via real-time analytics. |

| Risk Management | Vulnerable to supply chain disruptions. | Proactive; uses predictive analytics to mitigate risks. |

| Cost Efficiency | Reduces inventory holding costs. | Optimizes overall operational costs through automation. |

| Implementation Complexity | Relatively simple; focuses on lean inventory. | Complex; requires integration of multiple technologies. |

| Outcome | Lower waste and faster inventory turnover. | Improved productivity, quality, and scalability. |

Overview of Just-In-Time (JIT) Manufacturing

Just-In-Time (JIT) manufacturing is a production strategy aimed at reducing inventory costs by receiving goods only as they are needed in the production process. This approach minimizes waste and enhances efficiency by aligning raw material orders directly with production schedules. JIT relies heavily on precise demand forecasting and strong supplier relationships to maintain continuous workflow without overstocking.

Defining Smart Manufacturing in Modern Industry

Smart manufacturing integrates advanced technologies such as IoT, AI, and big data analytics to create highly automated and adaptive production systems that optimize efficiency and quality. Unlike traditional Just-In-Time methods, smart manufacturing enables real-time monitoring, predictive maintenance, and dynamic supply chain adjustments, reducing downtime and waste. Modern industry leverages these intelligent systems to enhance productivity while maintaining flexibility in meeting market demands.

Key Principles of Just-In-Time Production

Just-In-Time (JIT) production emphasizes minimizing inventory levels by aligning raw material orders directly with production schedules, reducing waste and improving cash flow. The key principles include continuous flow, pull system, and takt time, ensuring materials and products move seamlessly through the manufacturing process without delays. JIT relies on strong supplier relationships and precise demand forecasting to achieve efficiency and responsiveness in production.

Core Technologies Behind Smart Manufacturing

Smart Manufacturing leverages advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics to optimize production processes and enhance decision-making in real-time. Unlike Just-In-Time (JIT) which primarily focuses on inventory reduction and timing, Smart Manufacturing integrates cyber-physical systems and automation to enable predictive maintenance and adaptive manufacturing. Core technologies like machine learning algorithms and digital twins facilitate continuous process improvement and operational efficiency beyond traditional JIT methods.

Benefits of Implementing JIT in Manufacturing

Implementing Just-In-Time (JIT) in manufacturing significantly reduces inventory costs by aligning production schedules closely with demand, minimizing waste and storage expenses. This lean approach enhances operational efficiency, accelerates product delivery times, and improves cash flow management. The integration of JIT fosters a more responsive supply chain, enabling manufacturers to adapt swiftly to market fluctuations and customer requirements.

Advantages of Adopting Smart Manufacturing Systems

Smart manufacturing systems enhance production efficiency by integrating real-time data analytics and automation, reducing downtime and minimizing waste. These systems enable predictive maintenance, leading to lower operational costs and improved equipment longevity. Unlike traditional Just-In-Time models, smart manufacturing supports greater flexibility and responsiveness to market demand fluctuations through advanced IoT and AI technologies.

Challenges and Limitations of Just-In-Time Manufacturing

Just-In-Time (JIT) manufacturing faces challenges such as vulnerability to supply chain disruptions, limited inventory buffers, and high dependency on precise demand forecasting. These limitations can lead to production delays and increased costs if any component delivery is delayed or inaccuracies occur in demand predictions. In contrast, Smart Manufacturing integrates real-time data analytics and automation to enhance flexibility and mitigate risks associated with traditional JIT constraints.

Barriers to Successful Smart Manufacturing Integration

Barriers to successful smart manufacturing integration include high initial capital investment, lack of skilled workforce proficient in advanced technologies, and cybersecurity concerns associated with connected systems. Legacy equipment compatibility issues hinder seamless data exchange, while organizational resistance to change slows adoption of smart manufacturing processes. Furthermore, data management complexities and insufficient real-time analytics capabilities limit effective decision-making and operational optimization.

Comparative Analysis: Efficiency, Flexibility, and ROI

Just-In-Time (JIT) manufacturing minimizes inventory costs and reduces waste through precise demand forecasting, enhancing operational efficiency but often sacrificing flexibility in handling demand fluctuations. Smart Manufacturing leverages IoT, AI, and real-time data analytics to optimize processes dynamically, offering superior flexibility and adaptive responses to production changes, which can significantly improve return on investment (ROI) over time. Comparative analysis reveals that while JIT excels in cost control and streamlined workflows, Smart Manufacturing drives greater long-term efficiency and ROI by enabling proactive decision-making and scalable production capabilities.

Future Trends: Convergence of JIT and Smart Manufacturing

The future of manufacturing lies in the convergence of Just-In-Time (JIT) inventory systems with Smart Manufacturing technologies, leveraging IoT sensors, AI-driven analytics, and real-time data processing to optimize production workflows and reduce waste. This integration enables adaptive supply chain management, predictive maintenance, and enhanced decision-making, driving operational efficiency and responsiveness to market demands. Embracing this hybrid approach supports sustainable manufacturing practices and accelerates the transition toward Industry 4.0 frameworks.

Related Important Terms

Digital Lean Manufacturing

Digital Lean Manufacturing integrates Just-In-Time principles with advanced data analytics, IoT sensors, and AI-driven automation to optimize production efficiency and minimize waste. This smart manufacturing approach enhances supply chain responsiveness and real-time decision-making, surpassing traditional JIT methods by reducing downtime and improving product quality.

Predictive Just-In-Time

Predictive Just-In-Time integrates advanced data analytics and IoT sensors within Smart Manufacturing to anticipate demand fluctuations and optimize inventory levels, minimizing waste and production downtime. This approach enhances traditional Just-In-Time by enabling real-time decision-making and proactive supply chain adjustments based on predictive insights.

Autonomous Material Replenishment

Autonomous material replenishment in smart manufacturing leverages IoT sensors and AI algorithms to predict inventory needs and automatically trigger orders, significantly reducing stockouts and downtime. In contrast, Just-In-Time (JIT) relies on precise scheduling and supplier coordination but lacks the adaptive real-time responsiveness enabled by autonomous systems.

Cloud-Based Kanban

Cloud-Based Kanban integrates Just-In-Time principles with Smart Manufacturing by enabling real-time inventory tracking, automated replenishment, and seamless communication across production lines, reducing waste and improving workflow efficiency. Leveraging IoT sensors and data analytics, this system enhances decision-making accuracy and responsiveness, optimizing supply chain management and minimizing downtime.

Real-Time MES Integration

Real-Time MES integration in Just-In-Time manufacturing enhances inventory accuracy and production scheduling by synchronizing data across the shop floor, reducing waste and lead times. Smart Manufacturing leverages this integration to optimize processes through IoT connectivity and AI-driven analytics, enabling predictive maintenance and adaptive production adjustments.

Demand Sensing Algorithms

Demand sensing algorithms in smart manufacturing leverage real-time data and machine learning to predict customer demand more accurately than traditional just-in-time (JIT) methods, reducing inventory costs and minimizing stockouts. These algorithms enhance supply chain responsiveness by integrating diverse data sources, enabling manufacturers to adjust production schedules dynamically and improve overall operational efficiency.

Dynamic Inventory Visibility

Dynamic inventory visibility in Just-In-Time (JIT) manufacturing minimizes waste and reduces holding costs by synchronizing inventory levels precisely with production schedules, ensuring components arrive exactly when needed. Smart manufacturing leverages IoT sensors and real-time data analytics to enhance dynamic inventory visibility, enabling adaptive supply chain responses and predictive inventory management that optimize operational efficiency.

Supply Chain Digital Twin

Just-In-Time manufacturing minimizes inventory by synchronizing production with demand, but Smart Manufacturing enhances this approach through Supply Chain Digital Twins that simulate, monitor, and optimize end-to-end supply chain processes in real-time. Leveraging digital twins enables predictive analytics, reduces disruptions, and improves decision-making accuracy, driving superior efficiency and responsiveness across manufacturing operations.

AI-Driven Scheduling

AI-driven scheduling in smart manufacturing optimizes production timelines by analyzing real-time data, reducing downtime and inventory costs more effectively than traditional Just-In-Time methods. This technology enables dynamic adjustment to supply chain disruptions, enhancing operational efficiency and responsiveness.

Cyber-Physical Pull Systems

Cyber-Physical Pull Systems integrate real-time data from IoT sensors with advanced analytics to optimize Just-In-Time inventory, reducing waste and enhancing production agility. Smart Manufacturing leverages these systems to synchronize supply chains and manufacturing processes, ensuring efficient resource utilization and minimal lead times.

Just-In-Time vs Smart Manufacturing Infographic

industrydif.com

industrydif.com