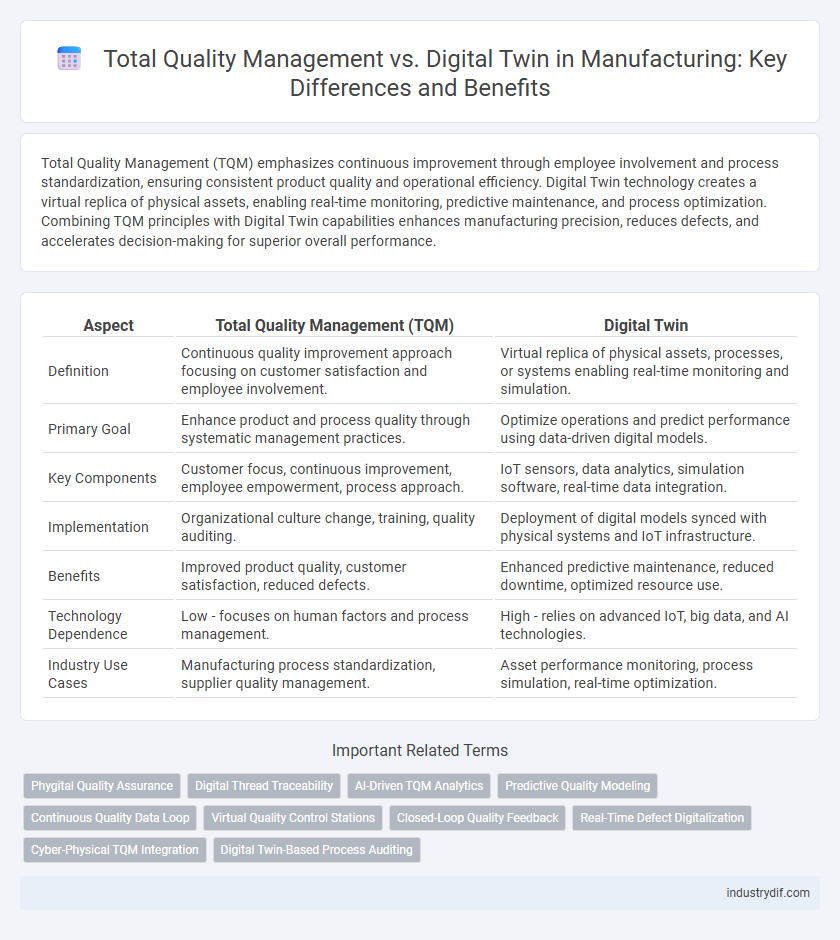

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and process standardization, ensuring consistent product quality and operational efficiency. Digital Twin technology creates a virtual replica of physical assets, enabling real-time monitoring, predictive maintenance, and process optimization. Combining TQM principles with Digital Twin capabilities enhances manufacturing precision, reduces defects, and accelerates decision-making for superior overall performance.

Table of Comparison

| Aspect | Total Quality Management (TQM) | Digital Twin |

|---|---|---|

| Definition | Continuous quality improvement approach focusing on customer satisfaction and employee involvement. | Virtual replica of physical assets, processes, or systems enabling real-time monitoring and simulation. |

| Primary Goal | Enhance product and process quality through systematic management practices. | Optimize operations and predict performance using data-driven digital models. |

| Key Components | Customer focus, continuous improvement, employee empowerment, process approach. | IoT sensors, data analytics, simulation software, real-time data integration. |

| Implementation | Organizational culture change, training, quality auditing. | Deployment of digital models synced with physical systems and IoT infrastructure. |

| Benefits | Improved product quality, customer satisfaction, reduced defects. | Enhanced predictive maintenance, reduced downtime, optimized resource use. |

| Technology Dependence | Low - focuses on human factors and process management. | High - relies on advanced IoT, big data, and AI technologies. |

| Industry Use Cases | Manufacturing process standardization, supplier quality management. | Asset performance monitoring, process simulation, real-time optimization. |

Defining Total Quality Management in Manufacturing

Total Quality Management (TQM) in manufacturing is a comprehensive approach focused on continuous improvement of product quality, processes, and customer satisfaction by involving all employees at every level. TQM emphasizes defect prevention, process standardization, and systematic problem-solving to reduce variability and enhance efficiency across production lines. Unlike Digital Twin technology, which creates virtual replicas for real-time monitoring and simulation, TQM centers on cultural transformation and quality-driven operational practices.

Understanding Digital Twin Technology

Digital Twin technology creates a virtual replica of physical manufacturing processes, enabling real-time monitoring and predictive maintenance to enhance product quality. Unlike Total Quality Management, which emphasizes continuous improvement through human-driven processes and data analysis, Digital Twins leverage IoT sensors and AI algorithms for dynamic simulation and optimization. Integrating Digital Twins can transform manufacturing quality control by offering precise insights, reducing downtime, and accelerating decision-making.

Key Principles of Total Quality Management

Total Quality Management (TQM) centers on continuous improvement, customer focus, and employee involvement to enhance product quality and operational efficiency. Digital Twin technology creates virtual replicas of physical assets, enabling real-time monitoring and predictive maintenance but does not inherently address the cultural and process-centric principles of TQM. Emphasizing leadership commitment, process approach, and integrated systems, TQM drives quality through organizational participation, whereas Digital Twin primarily supports data-driven decision-making in manufacturing.

Core Components of Digital Twin Systems

Core components of Digital Twin systems in manufacturing include real-time data acquisition, advanced simulation models, and intelligent analytics, enabling precise replication and optimization of physical assets. These elements facilitate predictive maintenance and performance monitoring, contrasting with Total Quality Management's emphasis on continuous process improvement through human-driven quality control methods. Integration of sensor networks, cloud computing, and machine learning algorithms defines the digital twin framework, driving enhanced operational efficiency and product quality in smart factories.

Benefits of Total Quality Management for Manufacturers

Total Quality Management (TQM) enhances manufacturing efficiency by fostering continuous improvement, reducing defects, and increasing customer satisfaction through systematic quality control processes. Its comprehensive approach integrates employee involvement and process optimization, leading to lower operational costs and higher product reliability. Manufacturers benefit from improved compliance with industry standards and stronger competitive advantage due to consistent, high-quality outputs.

Advantages of Implementing Digital Twins

Implementing Digital Twins in manufacturing offers real-time visualization and simulation of physical assets, enabling predictive maintenance and reducing downtime significantly. Unlike traditional Total Quality Management approaches, Digital Twins provide precise data integration for optimized process control and faster decision-making. Enhanced product lifecycle management and cost efficiency are additional benefits driving digital transformation in smart factories.

Integrating Total Quality Management with Digital Twin

Integrating Total Quality Management (TQM) with Digital Twin technology enhances manufacturing precision by enabling real-time monitoring and predictive analytics, leading to continuous process improvements and defect reduction. Digital Twins simulate production systems, providing actionable insights that align with TQM principles of systematic quality control and customer satisfaction. This synergy optimizes resource utilization, increases operational efficiency, and drives data-driven decision making throughout the manufacturing lifecycle.

Challenges in Adopting TQM vs Digital Twin Solutions

Adopting Total Quality Management (TQM) in manufacturing faces challenges such as resistance to cultural change, extensive employee training, and the difficulty of maintaining continuous process improvements. Digital Twin solutions encounter hurdles including high initial investment costs, data integration complexities, and the need for advanced analytics capabilities. Both approaches require careful alignment with organizational goals, but Digital Twins demand more sophisticated technological infrastructure compared to the people-centric focus of TQM implementation.

Industry Case Studies: TQM and Digital Twin in Action

Industry case studies reveal Total Quality Management (TQM) drives continuous improvement through employee involvement, standardized processes, and data-driven decision-making, enhancing product quality and operational efficiency. Digital Twin technology enables real-time simulation and monitoring of manufacturing systems, improving predictive maintenance and reducing downtime by replicating physical assets virtually. Combined implementation in manufacturing plants demonstrates significant gains in defect reduction, production speed, and resource optimization, validating the synergy between TQM frameworks and Digital Twin innovations.

Future Trends: The Convergence of TQM and Digital Twin in Manufacturing

The future of manufacturing is shaped by the convergence of Total Quality Management (TQM) and Digital Twin technologies, enhancing real-time quality control and predictive maintenance. Digital Twins create virtual replicas of production processes, enabling continuous monitoring and data-driven decision-making that aligns with TQM principles for continuous improvement. This integration drives operational excellence, reduces defects, and accelerates innovation through adaptive quality management systems.

Related Important Terms

Phygital Quality Assurance

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and process optimization, while Digital Twin technology enables real-time simulation and monitoring of manufacturing processes. Phygital Quality Assurance integrates TQM principles with Digital Twin analytics, enhancing defect detection and process control by combining physical inspections with digital data analysis for superior manufacturing quality.

Digital Thread Traceability

Digital Thread Traceability in manufacturing leverages Digital Twin technology to create a comprehensive, real-time data flow that enhances product lifecycle visibility and quality control at every production stage. Total Quality Management focuses on continuous improvement and standardized processes, whereas Digital Thread Traceability provides dynamic, actionable insights by linking physical products with their digital counterparts for precise tracking and analysis.

AI-Driven TQM Analytics

AI-driven Total Quality Management (TQM) analytics leverage machine learning algorithms and big data to identify defects, predict failures, and optimize production processes, enhancing product quality and reducing waste. Digital Twin technology creates virtual replicas of manufacturing systems that integrate real-time data with AI analytics, enabling continuous quality improvement and proactive decision-making in TQM frameworks.

Predictive Quality Modeling

Total Quality Management (TQM) emphasizes continuous improvement through systematic process control and employee involvement, while Digital Twin technology leverages real-time data and simulations to enable predictive quality modeling by forecasting defects and optimizing manufacturing parameters. Integrating Digital Twin with TQM enhances predictive accuracy, reduces downtime, and improves product consistency by enabling proactive decision-making based on virtual replication of production processes.

Continuous Quality Data Loop

Total Quality Management (TQM) integrates continuous quality improvement through systematic feedback loops, while Digital Twin technology enhances this process by creating real-time virtual replicas of manufacturing systems, enabling precise monitoring and proactive adjustments. The continuous quality data loop in Digital Twins ensures seamless data flow from physical assets to digital models, driving predictive analytics and accelerated decision-making in manufacturing quality control.

Virtual Quality Control Stations

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and standardized processes, while Digital Twin technology enables real-time simulation and monitoring of manufacturing systems. Virtual Quality Control Stations leverage Digital Twins to perform dynamic inspections and predictive quality analysis, enhancing accuracy and reducing production defects compared to traditional TQM methods.

Closed-Loop Quality Feedback

Total Quality Management (TQM) emphasizes continuous improvement through systematic closed-loop quality feedback involving real-time data collection and employee engagement. Digital Twin technology enhances closed-loop quality feedback by simulating manufacturing processes virtually, enabling rapid identification and correction of defects before physical production, thus optimizing product quality and reducing downtime.

Real-Time Defect Digitalization

Total Quality Management (TQM) emphasizes continuous improvement and defect reduction through systematic process audits and employee involvement, whereas Digital Twin technology enables real-time defect digitalization by creating dynamic virtual models of physical manufacturing processes that instantly reflect data changes and anomalies. Leveraging Digital Twin for defect detection enhances predictive maintenance, minimizes downtime, and streamlines quality control compared to conventional TQM methods reliant on periodic inspections and static data analysis.

Cyber-Physical TQM Integration

Total Quality Management (TQM) integrated with Digital Twin technology enables real-time monitoring and simulation of manufacturing processes, enhancing decision-making accuracy and operational efficiency. Cyber-Physical TQM integration leverages digital replicas to predict quality issues, optimize production workflows, and ensure continuous improvement through data-driven insights.

Digital Twin-Based Process Auditing

Digital Twin-Based Process Auditing enhances Total Quality Management by providing real-time, virtual replicas of manufacturing processes that enable continuous monitoring, predictive analytics, and instantaneous identification of deviations. This integration improves process accuracy, reduces downtime, and drives data-driven decision-making for superior product quality and operational efficiency.

Total Quality Management vs Digital Twin Infographic

industrydif.com

industrydif.com