Factory workers bring essential hands-on skills and real-time problem-solving abilities to the manufacturing floor, adapting to unexpected changes and physical tasks. Human digital twins replicate these workers' behaviors and processes virtually, enabling data-driven optimization, predictive maintenance, and enhanced safety without interrupting production. Combining human expertise with digital twin technology accelerates innovation and improves operational efficiency across manufacturing systems.

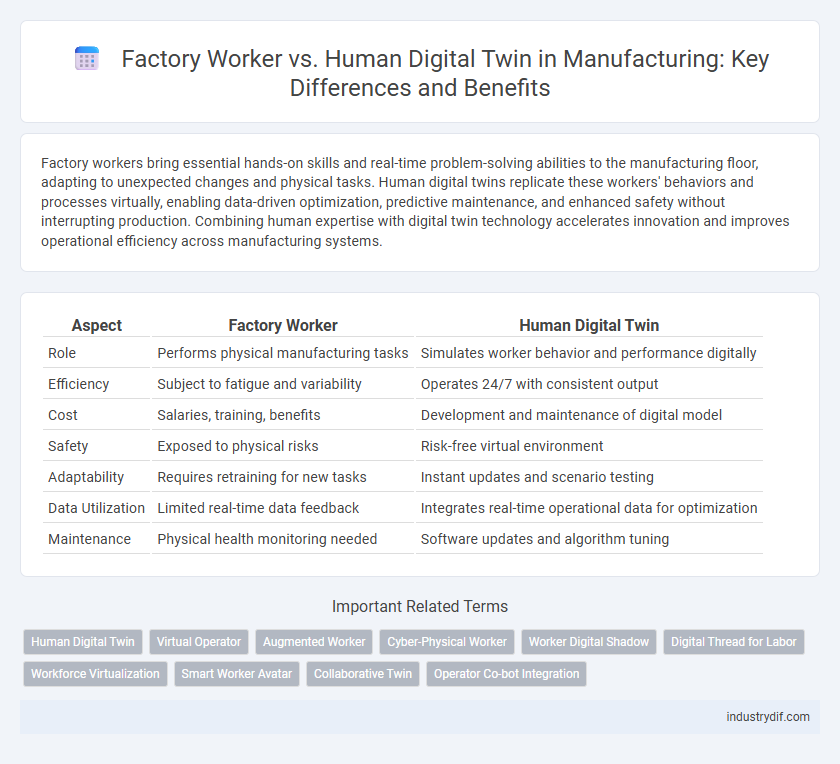

Table of Comparison

| Aspect | Factory Worker | Human Digital Twin |

|---|---|---|

| Role | Performs physical manufacturing tasks | Simulates worker behavior and performance digitally |

| Efficiency | Subject to fatigue and variability | Operates 24/7 with consistent output |

| Cost | Salaries, training, benefits | Development and maintenance of digital model |

| Safety | Exposed to physical risks | Risk-free virtual environment |

| Adaptability | Requires retraining for new tasks | Instant updates and scenario testing |

| Data Utilization | Limited real-time data feedback | Integrates real-time operational data for optimization |

| Maintenance | Physical health monitoring needed | Software updates and algorithm tuning |

Understanding the Role of Factory Workers

Factory workers perform essential hands-on tasks such as operating machinery, quality control, and assembly line management, ensuring production efficiency and safety in manufacturing environments. Human digital twins leverage real-time data and advanced simulations to replicate worker behaviors, optimize workflows, and predict performance outcomes. Understanding the complementary roles of factory workers and their digital counterparts helps enhance operational productivity and drives innovation in smart manufacturing processes.

Defining the Human Digital Twin in Manufacturing

A Human Digital Twin in manufacturing is a virtual replica of a factory worker that captures real-time data on physical activity, skills, and performance through IoT sensors and AI analytics. This digital counterpart enables predictive maintenance of human capabilities, personalized training programs, and safety improvements by simulating workflows and identifying inefficiencies. Unlike traditional factory workers, the Human Digital Twin integrates human behavior with machine data to optimize productivity and reduce downtime in smart factories.

Key Responsibilities: Factory Worker vs Human Digital Twin

Factory workers perform hands-on tasks such as machine operation, quality control, and manual assembly, directly influencing production output and workplace safety. Human digital twins simulate these physical workers' behaviors, monitoring real-time performance data, predicting maintenance needs, and optimizing workflow through advanced analytics. This digital representation enables proactive decision-making, reducing downtime and enhancing operational efficiency in manufacturing environments.

Skills and Training Requirements Compared

Factory workers require hands-on skills grounded in mechanical operations, manual dexterity, and basic machinery maintenance, often developed through vocational training and on-the-job experience. Human digital twins demand advanced digital literacy, data analysis capabilities, and proficiency with simulation software, necessitating specialized training in AI, IoT technologies, and virtual modeling. Training programs for digital twins emphasize continuous learning in emerging technologies, while factory worker training focuses more on practical skill enhancement and safety protocols.

Efficiency and Productivity Analysis

Factory workers contribute essential manual skills and adaptability on the production floor, but integrating Human Digital Twin technology enhances efficiency by providing real-time data analysis and predictive performance insights. Human Digital Twins simulate worker movements, fatigue, and task execution, enabling optimized workflow adjustments that reduce downtime and improve productivity metrics. Leveraging digital replicas facilitates precise monitoring of operational efficiency, leading to data-driven decision-making that surpasses traditional human labor assessment methods.

Impact on Workplace Safety

Factory workers benefit from enhanced workplace safety when complemented by human digital twins that simulate real-time hazardous scenarios to minimize risks. Human digital twins enable predictive maintenance and ergonomic analysis, reducing the likelihood of accidents and workplace injuries. This integration fosters a proactive safety culture by providing data-driven insights that support quick decision-making and targeted interventions.

Quality Assurance: Human Judgment vs Digital Precision

Factory workers apply human judgment to identify subtle defects and contextual quality issues that machines might overlook, relying on experience and intuition during quality assurance processes. Human digital twins leverage sensor data, AI algorithms, and real-time analytics to ensure precise quality control with higher consistency and faster detection of anomalies. Combining human insight with digital precision creates a comprehensive quality assurance system that significantly reduces errors and enhances product reliability.

Adaptability to Manufacturing Changes

Factory workers demonstrate hands-on adaptability to manufacturing changes by quickly adjusting workflows and machinery settings based on real-time conditions. Human digital twins leverage advanced simulation algorithms and real-time data integration to predict impacts of process modifications, enabling proactive adjustments without physical disruptions. Combining physical adaptability with digital predictive power enhances overall manufacturing agility and reduces downtime during transitions.

Cost Implications and ROI

Factory workers contribute essential manual labor with direct labor costs including wages, benefits, and training expenses, while human digital twins require significant upfront investment in advanced sensors, AI software, and data integration systems. Over time, digital twins can enhance ROI by minimizing downtime, optimizing workflows, and predicting maintenance needs, leading to reduced operational costs and improved production efficiency. Evaluating cost implications involves balancing initial technology investments against long-term gains in productivity and workforce augmentation.

Future Trends: Human Workforce and Digital Twins Integration

The integration of human digital twins with factory workers is transforming manufacturing by enabling real-time performance monitoring and predictive maintenance. Advanced sensors and AI-driven simulations enhance workforce training and operational efficiency, creating a synchronized environment where physical and digital workforces collaborate seamlessly. Future trends point to increased adoption of augmented reality and data analytics to optimize human-machine interactions and accelerate decision-making processes.

Related Important Terms

Human Digital Twin

Human Digital Twins in manufacturing offer real-time data simulation of factory workers' movements and performance, enabling predictive maintenance and process optimization. These digital replicas enhance safety and efficiency by identifying ergonomic risks and streamlining workflow through accurate behavioral analytics.

Virtual Operator

A Virtual Operator, representing the Human Digital Twin in manufacturing, replicates a factory worker's actions and decisions through advanced simulation and real-time data analysis, enhancing operational efficiency and minimizing errors. This digital counterpart enables predictive maintenance, process optimization, and remote monitoring, driving smarter factory automation and reducing downtime.

Augmented Worker

The Augmented Worker leverages Human Digital Twin technology to simulate and optimize factory worker performance in real-time, enhancing productivity and minimizing errors on the manufacturing floor. Integrating wearable sensors and AI-driven analytics, the digital twin provides actionable insights that improve training, safety, and operational efficiency.

Cyber-Physical Worker

A cyber-physical worker integrates human skills with digital technologies, creating a human digital twin that enhances factory efficiency through real-time data synchronization and predictive analytics. This fusion optimizes manufacturing processes by enabling adaptive decision-making and reducing downtime compared to traditional factory workers.

Worker Digital Shadow

The worker digital shadow captures real-time data from factory workers' actions, enabling precise monitoring and optimization of human performance on the manufacturing floor. Integrating this digital twin technology enhances productivity, reduces errors, and supports predictive maintenance by simulating worker interactions with machines and workflows.

Digital Thread for Labor

The integration of Human Digital Twins in manufacturing creates a comprehensive Digital Thread that captures real-time worker performance, ergonomic data, and skill metrics to optimize labor efficiency and safety. This digital representation enables predictive maintenance of workforce capabilities and personalized training, surpassing traditional factory worker monitoring methods.

Workforce Virtualization

Factory workers drive physical production processes, while human digital twins enable workforce virtualization by creating real-time virtual replicas of employees that simulate and optimize task performance. This virtualization enhances productivity, reduces downtime, and improves safety by integrating IoT sensors, AI analytics, and digital twin platforms for continuous workforce monitoring and predictive management.

Smart Worker Avatar

Smart Worker Avatars, or Human Digital Twins, enable real-time monitoring and simulation of factory workers' actions, enhancing productivity and safety by predicting potential risks and optimizing workflows. Unlike traditional factory workers, these digital counterparts leverage AI and IoT data to provide actionable insights, driving efficient decision-making on the manufacturing floor.

Collaborative Twin

Collaborative twins in manufacturing integrate factory workers with human digital twins, enabling real-time synchronization of physical actions and digital models to enhance productivity and safety. This synergy leverages IoT sensors and AI-driven analytics to optimize workflows, reduce downtime, and facilitate adaptive decision-making on the factory floor.

Operator Co-bot Integration

Factory workers enhance productivity through seamless operator co-bot integration, enabling real-time collaboration with human digital twins that simulate and optimize workflows. This synergy reduces downtime by predicting maintenance needs and improving task allocation, driving efficiency in smart manufacturing environments.

Factory Worker vs Human Digital Twin Infographic

industrydif.com

industrydif.com