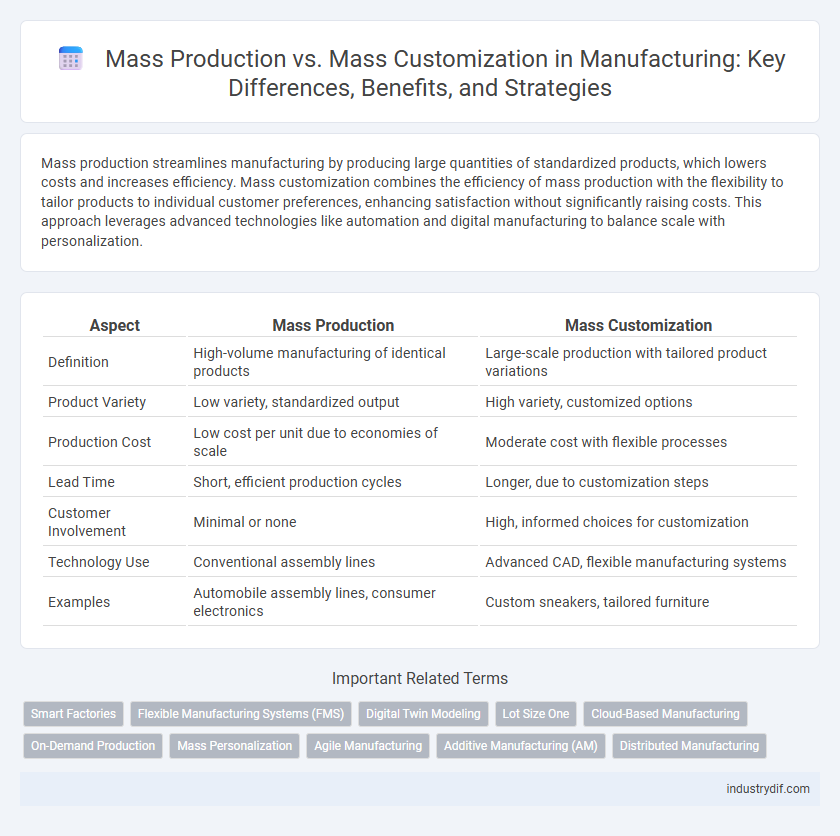

Mass production streamlines manufacturing by producing large quantities of standardized products, which lowers costs and increases efficiency. Mass customization combines the efficiency of mass production with the flexibility to tailor products to individual customer preferences, enhancing satisfaction without significantly raising costs. This approach leverages advanced technologies like automation and digital manufacturing to balance scale with personalization.

Table of Comparison

| Aspect | Mass Production | Mass Customization |

|---|---|---|

| Definition | High-volume manufacturing of identical products | Large-scale production with tailored product variations |

| Product Variety | Low variety, standardized output | High variety, customized options |

| Production Cost | Low cost per unit due to economies of scale | Moderate cost with flexible processes |

| Lead Time | Short, efficient production cycles | Longer, due to customization steps |

| Customer Involvement | Minimal or none | High, informed choices for customization |

| Technology Use | Conventional assembly lines | Advanced CAD, flexible manufacturing systems |

| Examples | Automobile assembly lines, consumer electronics | Custom sneakers, tailored furniture |

Introduction to Mass Production and Mass Customization

Mass production is a manufacturing process that produces large quantities of standardized products, utilizing assembly lines and automation to maximize efficiency and reduce costs. Mass customization combines the efficiency of mass production with the personalization of custom products, enabling the creation of tailored goods at near mass-production speeds. This approach leverages modular design, flexible manufacturing systems, and advanced information technologies to meet diverse customer preferences while maintaining economies of scale.

Historical Evolution of Manufacturing Strategies

Mass production emerged during the Industrial Revolution, revolutionizing manufacturing by enabling large-scale, standardized product output through assembly line techniques pioneered by Henry Ford. Over time, shifting consumer demands and advancements in digital technologies spurred the rise of mass customization, blending the efficiency of mass production with personalized product variations. This evolution reflects a strategic shift from uniformity-focused processes to flexible manufacturing systems that leverage automation, modular design, and data analytics to meet diverse customer preferences.

Defining Mass Production: Key Features and Benefits

Mass production is a manufacturing process that produces large quantities of standardized products using assembly line techniques and automation. Key features include high efficiency, low unit costs, and consistent quality achieved through repetitive tasks and specialized machinery. Benefits involve economies of scale, reduced production time, and the ability to meet high consumer demand with uniform products.

Understanding Mass Customization: Core Concepts and Advantages

Mass customization integrates advanced manufacturing technologies and flexible processes to produce personalized products at nearly mass production efficiency. This approach reduces inventory costs and enhances customer satisfaction by delivering tailored solutions while maintaining economies of scale. Key advantages include increased market differentiation and improved responsiveness to dynamic consumer demands.

Technology’s Role in Advancing Manufacturing Methods

Technology drives the evolution from mass production to mass customization by integrating advanced automation, artificial intelligence, and data analytics to enhance flexibility and efficiency in manufacturing processes. Additive manufacturing and smart factories enable real-time adjustments and personalized product variations without sacrificing scale or cost-effectiveness. These technological advancements empower manufacturers to meet diverse consumer demands while optimizing resource use and production speed.

Supply Chain Dynamics: Efficiency vs. Flexibility

Mass production streamlines supply chain dynamics by emphasizing efficiency through standardized processes, bulk procurement, and high-volume output, reducing per-unit costs and increasing throughput. Mass customization introduces supply chain flexibility, requiring adaptable logistics, modular inventory, and dynamic demand forecasting to accommodate varied customer specifications without compromising lead times. Balancing efficiency with flexibility demands integrated supply chain technologies, such as real-time data analytics and agile manufacturing systems, to optimize resource allocation and respond swiftly to market changes.

Cost Considerations and Economies of Scale

Mass production leverages economies of scale to significantly reduce unit costs by producing large volumes of standardized products, resulting in lower material and labor expenses per item. Mass customization, while offering personalized products, incurs higher costs due to smaller batch sizes, more complex supply chains, and greater operational flexibility demands. Balancing cost considerations requires manufacturers to evaluate the trade-offs between efficiency-driven mass production and the premium pricing enabled by tailored mass customization.

Customer Experience: Standardization vs. Personalization

Mass production delivers consistent quality and lower costs through standardized processes, ensuring reliable customer experiences with uniform products. Mass customization enhances customer satisfaction by offering personalized products tailored to individual preferences without sacrificing efficiency. Balancing standardization and personalization enables manufacturers to optimize operational costs while meeting diverse consumer demands for unique experiences.

Challenges and Limitations in Implementation

Mass production faces challenges such as high initial capital investment, inflexibility in adapting to changing consumer preferences, and significant inventory management costs. Mass customization struggles with balancing efficiency and personalization, requiring advanced technologies like AI and modular design, which can increase complexity and production time. Both approaches encounter limitations in supply chain coordination and scalability when attempting to optimize cost-effectiveness without compromising product quality.

Future Trends in Manufacturing: Integration of Mass Production and Customization

Future trends in manufacturing emphasize the seamless integration of mass production and mass customization through advanced technologies such as Industry 4.0, AI-driven automation, and flexible manufacturing systems. This hybrid approach enables manufacturers to achieve high efficiency and scalability while delivering personalized products tailored to consumer preferences. Data analytics and IoT connectivity further optimize production processes, fostering adaptive supply chains that respond dynamically to market demands.

Related Important Terms

Smart Factories

Smart factories leverage advanced automation and real-time data analytics to optimize mass production efficiency while enabling flexible mass customization tailored to individual customer preferences. Integrating IoT sensors and AI-driven systems allows manufacturers to rapidly switch between standardized large-scale output and personalized product variants without sacrificing quality or speed.

Flexible Manufacturing Systems (FMS)

Flexible Manufacturing Systems (FMS) enable manufacturers to transition from traditional mass production to mass customization by integrating automated machinery and computer-controlled processes that allow for rapid changes in product design and volume. This adaptability enhances operational efficiency, reduces lead times, and meets diverse customer demands without sacrificing economies of scale.

Digital Twin Modeling

Digital Twin Modeling enhances mass customization by creating virtual replicas of products and production processes, enabling real-time adjustments tailored to individual customer requirements. Unlike mass production's standardized output, this technology allows manufacturers to optimize efficiency while offering personalized solutions at scale.

Lot Size One

Mass production emphasizes large-scale manufacturing of uniform products to achieve economies of scale, while mass customization enables production of lot size one, tailoring products to individual customer specifications without sacrificing efficiency. Lot size one manufacturing integrates flexible automation and advanced digital technologies to deliver personalized products faster and at competitive costs.

Cloud-Based Manufacturing

Cloud-based manufacturing enhances mass customization by enabling real-time data integration, flexible production scheduling, and scalable resource allocation, outperforming traditional mass production in responsiveness and efficiency. Leveraging IoT connectivity, AI-driven analytics, and cloud platforms, manufacturers achieve personalized product variations at scale while reducing lead times and operational costs.

On-Demand Production

On-demand production in manufacturing enables mass customization by producing goods only when orders are received, reducing inventory costs and waste while meeting specific customer preferences. This approach contrasts with traditional mass production, which focuses on large-scale, uniform output driven by forecasted demand rather than real-time customization.

Mass Personalization

Mass personalization in manufacturing integrates advanced technologies such as AI and flexible automation to deliver customized products at scale, combining the efficiency of mass production with tailored consumer preferences. This approach enhances customer satisfaction and market responsiveness by enabling rapid adaptation to individual demands without sacrificing production speed or cost-effectiveness.

Agile Manufacturing

Agile manufacturing enhances mass customization by integrating flexible production systems and real-time data analytics to rapidly adapt to specific customer demands while maintaining efficient mass production workflows. This approach minimizes lead times and inventory costs, enabling manufacturers to deliver personalized products at scale without sacrificing operational efficiency.

Additive Manufacturing (AM)

Mass production emphasizes high-volume, uniform output using traditional manufacturing methods, while mass customization leverages Additive Manufacturing (AM) to efficiently produce tailored products at scale, reducing lead times and material waste. AM technologies such as 3D printing enable flexible design iterations and localized manufacturing, transforming supply chains and enhancing responsiveness in highly competitive markets.

Distributed Manufacturing

Distributed manufacturing enables mass customization by producing goods closer to end-users, reducing lead times and allowing flexibility in design variations. Unlike traditional mass production, which relies on centralized factories, distributed systems leverage localized facilities and digital technologies to efficiently meet diverse consumer demands at scale.

Mass Production vs Mass Customization Infographic

industrydif.com

industrydif.com