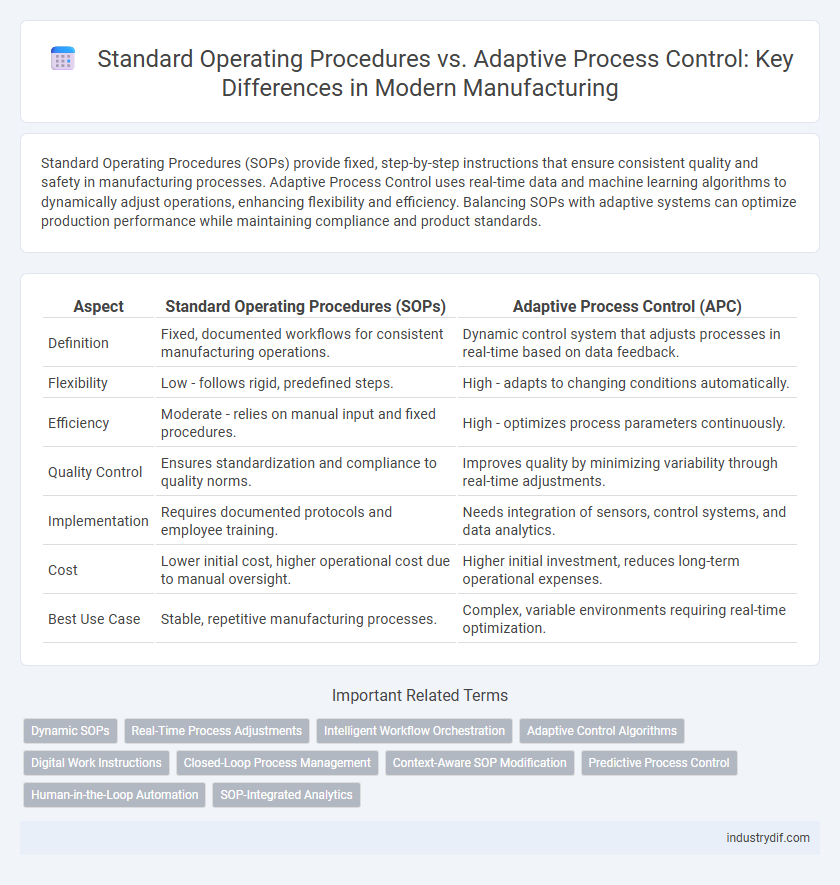

Standard Operating Procedures (SOPs) provide fixed, step-by-step instructions that ensure consistent quality and safety in manufacturing processes. Adaptive Process Control uses real-time data and machine learning algorithms to dynamically adjust operations, enhancing flexibility and efficiency. Balancing SOPs with adaptive systems can optimize production performance while maintaining compliance and product standards.

Table of Comparison

| Aspect | Standard Operating Procedures (SOPs) | Adaptive Process Control (APC) |

|---|---|---|

| Definition | Fixed, documented workflows for consistent manufacturing operations. | Dynamic control system that adjusts processes in real-time based on data feedback. |

| Flexibility | Low - follows rigid, predefined steps. | High - adapts to changing conditions automatically. |

| Efficiency | Moderate - relies on manual input and fixed procedures. | High - optimizes process parameters continuously. |

| Quality Control | Ensures standardization and compliance to quality norms. | Improves quality by minimizing variability through real-time adjustments. |

| Implementation | Requires documented protocols and employee training. | Needs integration of sensors, control systems, and data analytics. |

| Cost | Lower initial cost, higher operational cost due to manual oversight. | Higher initial investment, reduces long-term operational expenses. |

| Best Use Case | Stable, repetitive manufacturing processes. | Complex, variable environments requiring real-time optimization. |

Understanding Standard Operating Procedures in Manufacturing

Standard Operating Procedures (SOPs) in manufacturing provide detailed, standardized instructions for consistently executing specific tasks to ensure quality and safety compliance. SOPs help reduce variability, improve efficiency, and facilitate training by establishing clear, repeatable processes. Rigid adherence to SOPs contrasts with adaptive process control, which dynamically adjusts parameters based on real-time data to optimize production performance.

Defining Adaptive Process Control in Modern Factories

Adaptive Process Control in modern factories involves real-time monitoring and automated adjustments of manufacturing parameters to optimize performance and quality. Unlike Standard Operating Procedures, which rely on fixed, predefined steps, Adaptive Process Control uses data analytics and machine learning algorithms to respond dynamically to variations in materials, environmental conditions, and equipment status. This approach enhances efficiency, reduces waste, and improves product consistency by continuously fine-tuning processes based on feedback from sensors and production data.

Key Differences Between SOPs and Adaptive Process Control

Standard Operating Procedures (SOPs) provide fixed, step-by-step instructions to ensure consistency and compliance in manufacturing processes, while Adaptive Process Control uses real-time data analytics and machine learning algorithms to dynamically adjust process parameters. SOPs emphasize repeatability and strict adherence, whereas Adaptive Process Control prioritizes flexibility and optimization to respond to process variations and improve efficiency. The key difference lies in SOPs being static guidelines versus Adaptive Process Control's continuous, data-driven decision-making approach.

Benefits of Implementing SOPs in Manufacturing Workflows

Implementing Standard Operating Procedures (SOPs) in manufacturing workflows enhances consistency by establishing clear, repeatable steps that reduce variability and errors. SOPs improve compliance with industry regulations and quality standards, ensuring reliable product output and minimizing rework costs. Streamlined training processes result from SOPs, enabling faster onboarding and maintaining operational efficiency across shifts and teams.

Advantages of Adaptive Process Control for Real-Time Optimization

Adaptive Process Control enhances real-time optimization by continuously monitoring and adjusting manufacturing parameters based on live data, resulting in improved product quality and reduced waste. Unlike standard operating procedures, which follow fixed steps, adaptive control systems respond dynamically to variability in raw materials and equipment performance. This responsiveness increases process efficiency, minimizes downtime, and supports predictive maintenance strategies.

Challenges of Relying Solely on SOPs

Standard Operating Procedures (SOPs) often lack flexibility in dynamic manufacturing environments, leading to inefficiencies when unexpected variables arise. Relying solely on SOPs can result in delayed response times and increased error rates due to rigid adherence to predefined steps. Adaptive Process Control systems enhance manufacturing by continuously monitoring and adjusting operations in real-time, addressing variability that SOPs cannot manage alone.

Integrating SOPs with Adaptive Process Control Systems

Integrating Standard Operating Procedures (SOPs) with Adaptive Process Control Systems enhances manufacturing precision by combining fixed guidelines with real-time data-driven adjustments. This integration allows manufacturers to maintain consistent quality while dynamically responding to environmental variations and equipment fluctuations. Leveraging advanced sensors and machine learning algorithms within adaptive systems ensures SOPs are continuously optimized, reducing downtime and improving overall production efficiency.

Impact on Product Quality and Consistency

Standard Operating Procedures (SOPs) establish fixed protocols that ensure consistent execution of manufacturing tasks, leading to reliable product quality by minimizing variability. Adaptive Process Control systems dynamically adjust operational parameters in real time, optimizing manufacturing conditions to enhance product quality and respond to process fluctuations. Integrating Adaptive Process Control with SOPs significantly improves consistency and reduces defect rates by combining structured guidelines with responsive adjustments.

Case Studies: SOPs vs Adaptive Process Control in Action

Case studies comparing Standard Operating Procedures (SOPs) and Adaptive Process Control in manufacturing reveal significant differences in efficiency and responsiveness. SOPs provide consistent, repeatable workflows that ensure quality control but often lack flexibility to address real-time variations in production. In contrast, Adaptive Process Control leverages machine learning and sensor data to dynamically adjust parameters, resulting in improved throughput, reduced waste, and enhanced product quality under varying operational conditions.

Future Trends: Hybrid Approaches in Manufacturing Process Management

Hybrid approaches in manufacturing process management integrate Standard Operating Procedures (SOPs) with Adaptive Process Control systems to enhance operational flexibility and precision. Predictive analytics and machine learning algorithms enable real-time adjustments while maintaining compliance with established SOPs, optimizing efficiency and reducing downtime. Future trends emphasize seamless coupling of human expertise and automation, fostering dynamic workflows that respond to evolving production conditions and market demands.

Related Important Terms

Dynamic SOPs

Dynamic Standard Operating Procedures (SOPs) integrate real-time data analytics with adaptive process control to optimize manufacturing workflows and reduce downtime. These evolving SOPs enable immediate adjustments to process parameters, enhancing quality control and operational efficiency compared to static procedures.

Real-Time Process Adjustments

Standard Operating Procedures (SOPs) provide fixed, documented steps ensuring consistency in manufacturing processes, while Adaptive Process Control dynamically adjusts parameters in real-time based on sensor data and machine learning algorithms to optimize production efficiency and product quality. Real-time process adjustments enable manufacturers to respond immediately to variations, reducing defects and downtime compared to the static nature of SOPs.

Intelligent Workflow Orchestration

Standard Operating Procedures (SOPs) provide fixed, step-by-step instructions ensuring consistency in manufacturing, while Adaptive Process Control leverages real-time data and AI to dynamically adjust workflows for efficiency and quality. Intelligent Workflow Orchestration integrates these approaches by using machine learning algorithms to optimize and automate production sequences, enhancing responsiveness and minimizing downtime.

Adaptive Control Algorithms

Adaptive control algorithms dynamically adjust manufacturing processes in real-time based on sensor data and environmental changes, enhancing efficiency and product quality. These algorithms outperform traditional Standard Operating Procedures by enabling continuous optimization and reducing downtime through predictive adjustments.

Digital Work Instructions

Standard Operating Procedures (SOPs) provide fixed, step-by-step guidelines in manufacturing, ensuring consistency but often lacking flexibility. Adaptive Process Control leverages Digital Work Instructions that dynamically update in real-time, enhancing operational efficiency and reducing errors by tailoring tasks to current conditions and data inputs.

Closed-Loop Process Management

Standard Operating Procedures (SOPs) provide fixed guidelines for manufacturing tasks, ensuring consistency but limiting flexibility in dynamic environments. Adaptive Process Control utilizes real-time data feedback to continuously adjust operations, enabling closed-loop process management that enhances efficiency and responsiveness.

Context-Aware SOP Modification

Context-aware SOP modification enhances manufacturing efficiency by integrating real-time data and adaptive process control to dynamically update Standard Operating Procedures based on current production variables. This approach minimizes downtime and quality deviations by ensuring that SOPs respond promptly to operational changes and environmental factors.

Predictive Process Control

Standard Operating Procedures (SOPs) provide fixed guidelines that ensure consistency in manufacturing, while Adaptive Process Control leverages real-time data and machine learning algorithms to predict and adjust process parameters dynamically. Predictive Process Control enhances efficiency by anticipating deviations and minimizing downtime through continuous monitoring and proactive adjustments.

Human-in-the-Loop Automation

Human-in-the-Loop Automation integrates real-time human decision-making with Adaptive Process Control to enhance manufacturing flexibility and responsiveness, contrasting with Standard Operating Procedures that rely on fixed, manual instructions. This synergy optimizes process efficiency and quality by combining automated data analysis with expert human intervention.

SOP-Integrated Analytics

Standard Operating Procedures (SOPs) ensure consistent quality and compliance by defining fixed workflows, while SOP-Integrated Analytics enable real-time monitoring and data-driven adjustments within these workflows to enhance efficiency and reduce defects. Integrating analytics into SOPs transforms static instructions into dynamic processes, allowing manufacturers to optimize operations through predictive insights and adaptive controls without deviating from established standards.

Standard Operating Procedures vs Adaptive Process Control Infographic

industrydif.com

industrydif.com