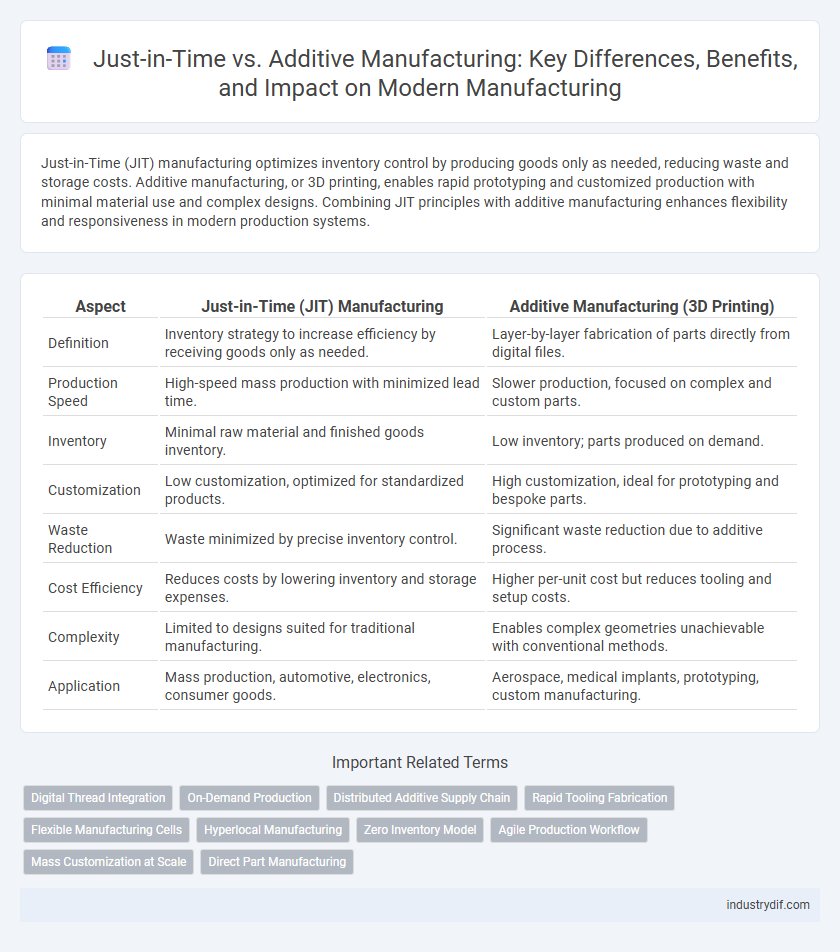

Just-in-Time (JIT) manufacturing optimizes inventory control by producing goods only as needed, reducing waste and storage costs. Additive manufacturing, or 3D printing, enables rapid prototyping and customized production with minimal material use and complex designs. Combining JIT principles with additive manufacturing enhances flexibility and responsiveness in modern production systems.

Table of Comparison

| Aspect | Just-in-Time (JIT) Manufacturing | Additive Manufacturing (3D Printing) |

|---|---|---|

| Definition | Inventory strategy to increase efficiency by receiving goods only as needed. | Layer-by-layer fabrication of parts directly from digital files. |

| Production Speed | High-speed mass production with minimized lead time. | Slower production, focused on complex and custom parts. |

| Inventory | Minimal raw material and finished goods inventory. | Low inventory; parts produced on demand. |

| Customization | Low customization, optimized for standardized products. | High customization, ideal for prototyping and bespoke parts. |

| Waste Reduction | Waste minimized by precise inventory control. | Significant waste reduction due to additive process. |

| Cost Efficiency | Reduces costs by lowering inventory and storage expenses. | Higher per-unit cost but reduces tooling and setup costs. |

| Complexity | Limited to designs suited for traditional manufacturing. | Enables complex geometries unachievable with conventional methods. |

| Application | Mass production, automotive, electronics, consumer goods. | Aerospace, medical implants, prototyping, custom manufacturing. |

Overview of Just-in-Time (JIT) Manufacturing

Just-in-Time (JIT) manufacturing is a production strategy aimed at minimizing inventory and reducing waste by receiving materials only as they are needed in the production process. This method enhances efficiency and decreases carrying costs by synchronizing production schedules closely with supplier deliveries and customer demand. JIT relies heavily on precise forecasting and streamlined communication to ensure components arrive exactly when required, preventing overproduction and excess stock.

Fundamentals of Additive Manufacturing (AM)

Additive Manufacturing (AM) builds products layer by layer directly from digital models, enabling complex geometries and material efficiency unattainable by traditional subtractive methods. Unlike Just-in-Time (JIT) production that optimizes inventory flow and reduces waste through precise timing, AM minimizes lead times by eliminating tooling and setup requirements. Key technologies in AM include selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA), which facilitate rapid prototyping and customized manufacturing.

Key Differences: JIT vs Additive Manufacturing

Just-in-Time (JIT) manufacturing focuses on reducing inventory costs by producing goods only as they are needed, relying heavily on precise demand forecasting and efficient supply chain management. Additive manufacturing, or 3D printing, builds products layer-by-layer directly from digital models, enabling complex geometries and rapid prototyping without the constraints of traditional tooling. While JIT optimizes production timing to minimize waste, additive manufacturing optimizes design flexibility and customization with minimal material wastage.

Inventory Management in JIT vs AM

Just-in-Time (JIT) manufacturing minimizes inventory levels by synchronizing production closely with demand, reducing storage costs and waste. Additive Manufacturing (AM) supports a more flexible inventory strategy by allowing on-demand production of parts, which decreases the need for large, finished goods inventories. While JIT relies on precise supply chain coordination to avoid stockouts, AM enables decentralized production and rapid prototyping, enhancing responsiveness to changing customer requirements.

Cost Efficiency and Resource Utilization

Just-in-Time (JIT) manufacturing minimizes inventory carrying costs by producing goods only as needed, reducing waste and optimizing cash flow. Additive manufacturing enhances resource utilization through precision material deposition, significantly decreasing raw material waste and enabling cost-effective small-batch production. Combining JIT principles with additive manufacturing technologies can drive superior cost efficiency and sustainable resource management in modern manufacturing environments.

Production Flexibility and Customization

Just-in-Time (JIT) manufacturing emphasizes minimizing inventory and streamlining production schedules, which enhances efficiency but limits flexibility and customization due to reliance on standardized processes. Additive manufacturing, or 3D printing, offers superior production flexibility by enabling on-demand fabrication of complex, customized parts without the need for retooling. This contrast allows additive manufacturing to meet diverse customer specifications and rapidly adapt to design changes, making it ideal for highly customized and low-volume production runs.

Lead Time Reduction Strategies

Just-in-Time (JIT) manufacturing reduces lead time by synchronizing production schedules with demand, minimizing inventory and accelerating workflow efficiency. Additive manufacturing shortens lead times through rapid prototyping and on-demand production, eliminating the need for tooling and enabling quicker design iterations. Combining JIT with additive manufacturing enhances flexibility and responsiveness, optimizing supply chain operations and reducing overall production cycle time.

Quality Control in JIT and AM Processes

Just-in-Time (JIT) manufacturing emphasizes stringent quality control through real-time inspection and minimal inventory to reduce defects and waste, ensuring components meet specifications before proceeding to the next stage. Additive Manufacturing (AM) leverages layer-by-layer production and integrated monitoring systems to detect anomalies early, allowing for precise adjustments and consistently high-quality outputs. Both methods prioritize quality assurance but differ in process control approaches, with JIT focusing on supplier consistency and AM benefiting from digital traceability and customization capabilities.

Environmental Impact and Sustainability

Just-in-Time (JIT) manufacturing reduces waste by minimizing inventory and lowering energy consumption through streamlined production schedules, enhancing resource efficiency and decreasing carbon emissions. Additive manufacturing (3D printing) supports sustainability by using precise amounts of raw materials, reducing scrap and enabling lightweight designs that lower transportation emissions. Integrating JIT with additive manufacturing can further optimize environmental impact, promoting a circular economy and advancing sustainable manufacturing practices.

Future Trends in Manufacturing: JIT and AM Integration

Future trends in manufacturing emphasize the integration of Just-in-Time (JIT) and Additive Manufacturing (AM) to enhance operational efficiency and reduce waste. This convergence enables dynamic inventory management by leveraging AM's capability for rapid prototyping and on-demand production, aligning closely with JIT principles. Advanced software analytics and IoT technologies are accelerating this integration, optimizing supply chains and enabling more agile, responsive manufacturing systems.

Related Important Terms

Digital Thread Integration

Just-in-Time manufacturing streamlines inventory control by minimizing waste through precise production scheduling, while Additive Manufacturing enhances design flexibility and rapid prototyping. Integrating a Digital Thread enables seamless data flow across production stages, improving traceability, real-time decision-making, and synchronization between traditional and additive processes.

On-Demand Production

Just-in-Time manufacturing minimizes inventory by synchronizing production schedules with demand, reducing waste and storage costs. Additive Manufacturing enables highly flexible on-demand production by creating parts layer-by-layer, allowing rapid customization and reduced lead times.

Distributed Additive Supply Chain

Distributed additive supply chains leverage localized 3D printing facilities to reduce lead times and inventory costs, contrasting with just-in-time manufacturing's reliance on tightly scheduled, centralized production and delivery. This approach enables real-time customization and rapid response to demand fluctuations while minimizing transportation emissions and enhancing supply chain resilience.

Rapid Tooling Fabrication

Just-in-Time (JIT) manufacturing reduces inventory costs by synchronizing production with demand, but often faces limitations in tooling lead times. Additive manufacturing accelerates rapid tooling fabrication by enabling direct, on-demand creation of customized tools, significantly shortening production cycles and enhancing flexibility in manufacturing processes.

Flexible Manufacturing Cells

Flexible manufacturing cells enhance production efficiency by integrating just-in-time (JIT) principles with additive manufacturing techniques, allowing for rapid response to demand fluctuations and minimizing inventory costs. The adaptability of additive processes within these cells supports customized, low-volume production runs while maintaining JIT's emphasis on reducing waste and lead times.

Hyperlocal Manufacturing

Just-in-Time manufacturing minimizes inventory costs by producing goods only as needed, while Additive Manufacturing enables Hyperlocal Manufacturing through 3D printing, which significantly reduces transportation time and supports on-demand production close to the end user. Hyperlocal Manufacturing leverages Additive Manufacturing's flexibility to customize products rapidly, decreasing lead times and enhancing supply chain resilience within localized markets.

Zero Inventory Model

Just-in-Time manufacturing minimizes inventory by synchronizing production schedules with demand to reduce costs and waste, while Additive Manufacturing enables a Zero Inventory Model by producing parts on-demand through layer-by-layer fabrication, eliminating the need for extensive storage. This approach enhances flexibility and responsiveness in supply chains, reducing lead times and inventory holding costs significantly.

Agile Production Workflow

Just-in-Time (JIT) manufacturing minimizes inventory through precise scheduling, enabling lean and responsive production workflows, while additive manufacturing offers rapid prototyping and customization within agile production environments. Integrating additive manufacturing with JIT principles enhances flexibility, reduces lead times, and supports adaptive supply chain strategies in modern manufacturing.

Mass Customization at Scale

Just-in-Time manufacturing optimizes inventory and reduces waste by synchronizing production schedules with demand, but may struggle with flexibility in mass customization at scale. Additive manufacturing enables highly customizable production with rapid design iterations, making it ideal for mass customization while maintaining efficient scalability and reducing lead times.

Direct Part Manufacturing

Direct Part Manufacturing (DPM) in additive manufacturing enables on-demand production of complex parts with minimal lead time and reduced inventory costs, contrasting sharply with Just-in-Time (JIT) manufacturing's reliance on precise supply chain synchronization. DPM's digital-driven process supports rapid prototyping and customization, improving agility and reducing waste while overcoming JIT vulnerabilities such as supplier delays and inventory shortages.

Just-in-Time vs Additive Manufacturing Infographic

industrydif.com

industrydif.com