Inventory management emphasizes maintaining optimal stock levels to prevent shortages and reduce holding costs, ensuring smooth production flow. Demand-Driven Material Requirements Planning (DDMRP) aligns inventory replenishment with actual customer demand using strategically positioned stock buffers, improving responsiveness and reducing excess inventory. Integrating DDMRP into inventory management enhances manufacturing efficiency by synchronizing supply with real-time market needs.

Table of Comparison

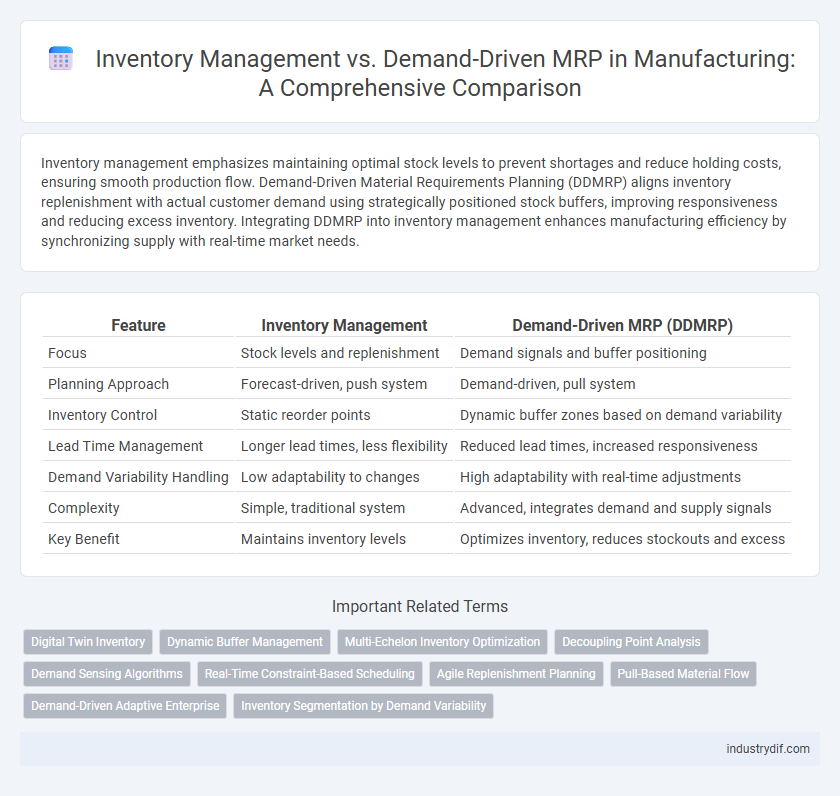

| Feature | Inventory Management | Demand-Driven MRP (DDMRP) |

|---|---|---|

| Focus | Stock levels and replenishment | Demand signals and buffer positioning |

| Planning Approach | Forecast-driven, push system | Demand-driven, pull system |

| Inventory Control | Static reorder points | Dynamic buffer zones based on demand variability |

| Lead Time Management | Longer lead times, less flexibility | Reduced lead times, increased responsiveness |

| Demand Variability Handling | Low adaptability to changes | High adaptability with real-time adjustments |

| Complexity | Simple, traditional system | Advanced, integrates demand and supply signals |

| Key Benefit | Maintains inventory levels | Optimizes inventory, reduces stockouts and excess |

Introduction to Inventory Management in Manufacturing

Inventory management in manufacturing involves overseeing raw materials, work-in-progress, and finished goods to ensure optimal stock levels that balance supply with production demand. Effective inventory control reduces carrying costs, mitigates stockouts, and enhances production efficiency through just-in-time replenishment strategies. Advanced techniques like barcode scanning, RFID tags, and inventory management software improve accuracy and real-time tracking for seamless manufacturing operations.

Overview of Demand-Driven Material Requirements Planning (DDMRP)

Demand-Driven Material Requirements Planning (DDMRP) revolutionizes inventory management by integrating actual demand signals into material planning, reducing lead times and minimizing excess stock. This method prioritizes strategic inventory positioning, dynamic buffer profiles, and demand-driven replenishment to optimize supply chain responsiveness and improve production flow. Companies adopting DDMRP experience enhanced agility and accuracy in meeting customer demand while controlling inventory costs effectively.

Key Differences Between Inventory Management and DDMRP

Inventory management primarily focuses on tracking stock levels, reorder points, and safety stock to ensure sufficient materials for production, while Demand-Driven Material Requirements Planning (DDMRP) integrates actual market demand signals to dynamically adjust inventory buffers and production schedules. DDMRP emphasizes strategic decoupling points and buffer zones to reduce lead times and minimize stockouts, contrasting with traditional inventory management's reliance on forecast accuracy and fixed reorder policies. The key difference lies in DDMRP's adaptive, demand-driven approach that enhances responsiveness and aligns material flow directly with customer demand fluctuations.

Benefits of Traditional Inventory Management

Traditional inventory management ensures consistent stock availability by maintaining safety stock levels, reducing the risk of stockouts in manufacturing operations. It facilitates straightforward planning and order processing, enabling manufacturers to predict procurement needs with historical data accurately. This method offers stability and control in supply chain operations, particularly in environments with predictable demand patterns.

Advantages of Demand-Driven Material Requirements Planning

Demand-Driven Material Requirements Planning (DDMRP) improves inventory management by dynamically adjusting inventory levels based on actual demand signals, reducing excess stock and minimizing stockouts. It enhances production responsiveness and forecast accuracy through real-time data integration, leading to optimized material flow and lower carrying costs. DDMRP supports better alignment between supply and demand, increasing service levels and operational efficiency in manufacturing environments.

Common Challenges in Inventory Management

Common challenges in inventory management include inaccurate demand forecasting, leading to overstocking or stockouts, and inefficient tracking systems that result in poor visibility of inventory levels. These issues cause increased holding costs, delayed production schedules, and reduced customer satisfaction. Demand-Driven Material Requirements Planning (DDMRP) addresses these challenges by enhancing real-time responsiveness and aligning inventory replenishment with actual consumption patterns.

Implementing DDMRP in Manufacturing Operations

Implementing Demand-Driven Material Requirements Planning (DDMRP) in manufacturing operations enhances inventory management by aligning stock levels with real-time demand signals, reducing excess inventory and minimizing stockouts. This approach integrates buffer profiles and strategic decoupling points to optimize material flow, improving production agility and responsiveness. Leveraging DDMRP software tools allows manufacturers to dynamically adjust replenishment priorities, resulting in improved on-time delivery and lower holding costs.

Impact on Supply Chain Efficiency

Inventory Management optimizes stock levels to minimize holding costs while ensuring product availability, directly influencing supply chain fluidity. Demand-Driven Material Requirements Planning (DDMRP) utilizes real-time demand signals to adjust inventory buffers, significantly reducing lead times and mitigating supply chain variability. Implementing DDMRP enhances supply chain responsiveness and efficiency by aligning procurement and production closely with actual market demand.

Metrics for Evaluating Inventory Performance

Inventory management metrics such as turnover rate, carrying cost, and stockout frequency provide baseline data to assess inventory efficiency, while demand-driven material requirements planning (DDMRP) emphasizes flow and buffer performance indicators like buffer penetration and on-hand position accuracy. Measuring inventory turnover rates reveals how effectively inventory is cycled, but DDMRP's buffer management metrics offer real-time visibility into demand variability and supply chain responsiveness. Combining traditional metrics with DDMRP's dynamic indicators enables manufacturers to optimize stock levels, reduce carrying costs, and improve service levels in fluctuating market conditions.

Choosing the Right Strategy for Manufacturing Success

Inventory management optimizes stock levels to reduce holding costs and avoid stockouts, ensuring smooth production flow in manufacturing. Demand-Driven Material Requirements Planning (DDMRP) aligns inventory replenishment with actual market demand, enhancing responsiveness and minimizing excess inventory. Selecting the right strategy depends on factors like product complexity, lead times, and demand variability to maximize operational efficiency and customer satisfaction.

Related Important Terms

Digital Twin Inventory

Digital Twin Inventory enhances Demand-Driven Material Requirements Planning by simulating real-time inventory status, enabling precise adjustments to manufacturing schedules and reducing stockouts. This digital replication integrates seamlessly with Inventory Management systems, optimizing supply chain visibility and accelerating response to market fluctuations.

Dynamic Buffer Management

Dynamic Buffer Management in Demand-Driven Material Requirements Planning (DDMRP) enhances inventory management by adjusting stock levels in real-time based on actual demand and supply variability, reducing excess inventory and minimizing stockouts. Unlike traditional inventory management methods, DDMRP utilizes strategically placed buffers that adapt dynamically, improving production flow and responsiveness in manufacturing environments.

Multi-Echelon Inventory Optimization

Multi-Echelon Inventory Optimization (MEIO) enhances Inventory Management by synchronizing stock levels across all tiers of the supply chain, reducing excess inventory and minimizing stockouts. Demand-Driven Material Requirements Planning (DDMRP) integrates MEIO principles by adjusting replenishment dynamically based on real-time demand signals, improving service levels and operational efficiency in complex manufacturing networks.

Decoupling Point Analysis

Inventory Management relies on maintaining buffer stock to absorb demand fluctuations, while Demand-Driven Material Requirements Planning (DDMRP) strategically positions decoupling points to optimize flow and reduce lead times. Decoupling Point Analysis in DDMRP identifies critical inventory nodes where stock buffers mitigate variability, enabling responsive and agile manufacturing processes.

Demand Sensing Algorithms

Demand Sensing Algorithms enhance Demand-Driven Material Requirements Planning by providing real-time demand data analysis, enabling more accurate inventory forecasting and reducing stockouts. These algorithms leverage advanced machine learning to rapidly adjust supply chain inputs, improving responsiveness and minimizing excess inventory in manufacturing operations.

Real-Time Constraint-Based Scheduling

Inventory Management primarily tracks stock levels to prevent shortages or overstock, while Demand-Driven Material Requirements Planning (DDMRP) integrates real-time constraint-based scheduling to dynamically adjust production schedules according to current demand and supply chain constraints. This approach enhances manufacturing efficiency by minimizing lead times and reducing inventory carrying costs through adaptive buffer positioning and constraint prioritization.

Agile Replenishment Planning

Agile replenishment planning enhances demand-driven material requirements planning by dynamically adjusting inventory levels based on real-time demand signals, reducing excess stock and minimizing shortages. This approach integrates just-in-time replenishment with advanced forecasting algorithms to optimize inventory turnover and improve supply chain responsiveness in manufacturing.

Pull-Based Material Flow

Pull-based material flow in inventory management prioritizes real-time customer demand signals to trigger production and replenishment, reducing excess inventory and minimizing waste. Demand-Driven Material Requirements Planning (DDMRP) enhances this approach by integrating buffer profiles and dynamic adjustments, ensuring materials are available exactly when needed to optimize manufacturing efficiency.

Demand-Driven Adaptive Enterprise

Demand-Driven Material Requirements Planning (DDMRP) enhances Inventory Management by aligning stock levels with actual market demand, reducing excess inventory and minimizing stockouts in manufacturing operations. The Demand-Driven Adaptive Enterprise leverages real-time data and adaptive supply chain strategies to optimize production schedules, improve responsiveness, and increase overall operational efficiency.

Inventory Segmentation by Demand Variability

Inventory Management traditionally relies on static reorder points, often leading to excess stock or shortages, whereas Demand-Driven Material Requirements Planning (DDMRP) uses inventory segmentation based on demand variability to dynamically adjust stock buffers. This segmentation allows DDMRP to categorize inventory into strategic, tactical, and operational decoupling points, optimizing buffer levels and improving responsiveness to fluctuating demand patterns in manufacturing environments.

Inventory Management vs Demand-Driven Material Requirements Planning Infographic

industrydif.com

industrydif.com