Standardization in manufacturing ensures consistent quality, reduces costs, and streamlines production by using uniform components and processes. Hyper-personalization, on the other hand, tailors products to individual customer preferences, enhancing customer satisfaction and brand loyalty. Balancing these approaches allows manufacturers to achieve operational efficiency while meeting diverse market demands.

Table of Comparison

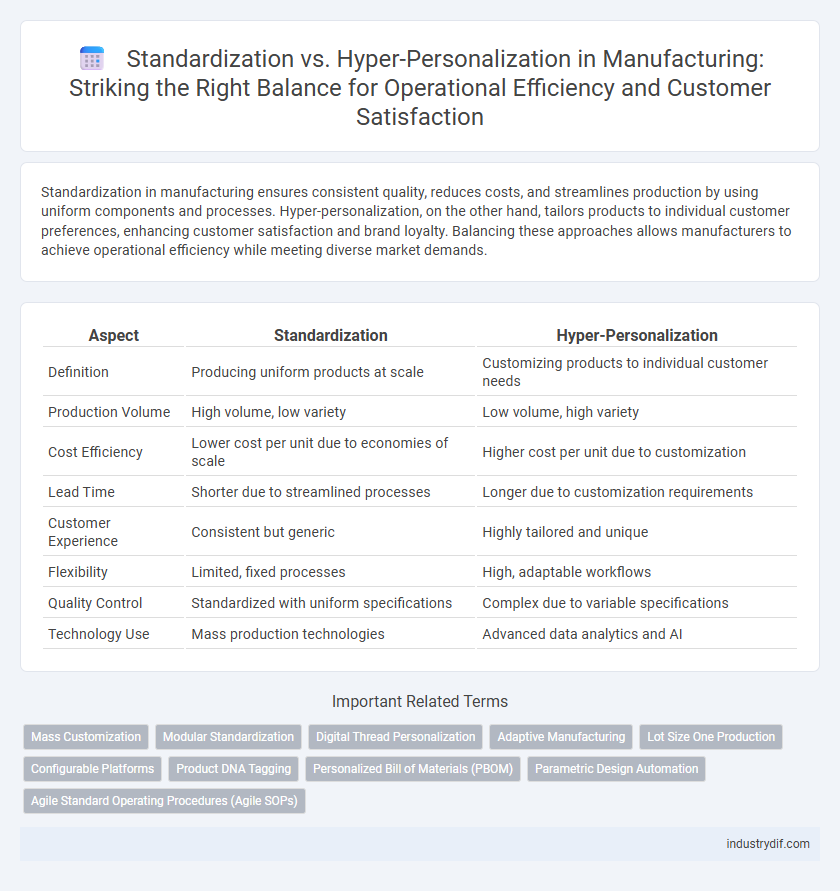

| Aspect | Standardization | Hyper-Personalization |

|---|---|---|

| Definition | Producing uniform products at scale | Customizing products to individual customer needs |

| Production Volume | High volume, low variety | Low volume, high variety |

| Cost Efficiency | Lower cost per unit due to economies of scale | Higher cost per unit due to customization |

| Lead Time | Shorter due to streamlined processes | Longer due to customization requirements |

| Customer Experience | Consistent but generic | Highly tailored and unique |

| Flexibility | Limited, fixed processes | High, adaptable workflows |

| Quality Control | Standardized with uniform specifications | Complex due to variable specifications |

| Technology Use | Mass production technologies | Advanced data analytics and AI |

Introduction: Defining Standardization and Hyper-Personalization in Manufacturing

Standardization in manufacturing refers to producing uniform products using consistent processes to ensure efficiency, quality control, and cost reduction. Hyper-personalization involves tailoring products and services to individual customer preferences through advanced technologies like AI and IoT. Balancing these approaches impacts supply chain agility, production scalability, and customer satisfaction in modern manufacturing environments.

Historical Perspective: Evolution of Manufacturing Paradigms

Manufacturing has evolved from rigid standardization models dominating the early Industrial Revolution to the rise of hyper-personalization enabled by advanced digital technologies and flexible production systems. Historically, standardization focused on mass production efficiency through uniform parts and processes, while recent shifts emphasize customization driven by consumer demand and Industry 4.0 innovations such as additive manufacturing and IoT integration. This evolution reflects a paradigm shift from economies of scale to economies of scope, balancing cost efficiency with personalized product differentiation.

Key Benefits of Standardization in Industrial Processes

Standardization in industrial processes enhances operational efficiency by streamlining production workflows and reducing variability, leading to consistent product quality. It lowers manufacturing costs through economies of scale and simplified supply chain management, while ensuring regulatory compliance and safety standards. These benefits contribute to improved scalability and faster time-to-market for industrial manufacturers.

Advantages of Hyper-Personalization for Modern Manufacturers

Hyper-personalization enables modern manufacturers to tailor products and services precisely to individual customer preferences, enhancing customer satisfaction and loyalty. Utilizing advanced data analytics and AI-driven insights, manufacturers can optimize production processes, reduce waste, and improve overall efficiency. This approach fosters innovation, allowing companies to differentiate themselves in competitive markets by delivering unique, customized solutions at scale.

Technology Drivers: Automation, AI, and Data Analytics

Automation streamlines manufacturing processes by enabling consistent production standards, while AI enhances hyper-personalization through real-time customization based on consumer data. Data analytics drives decision-making by identifying patterns that optimize both standardized efficiency and bespoke product variations. Integrating these technologies allows manufacturers to balance mass production speed with tailored customer experiences, leveraging smart systems for adaptive manufacturing.

Challenges and Limitations of Standardization

Standardization in manufacturing often faces challenges such as limited flexibility to meet diverse customer needs and slower adaptation to market changes. This approach can lead to inefficiencies in addressing unique client specifications, resulting in lower customer satisfaction. Additionally, rigid standard processes may hinder innovation and responsiveness, impacting overall competitiveness in dynamic industries.

Complexities and Risks in Achieving Hyper-Personalization

Achieving hyper-personalization in manufacturing introduces significant complexities such as increased supply chain variability, production scheduling challenges, and heightened quality control demands. These risks include higher costs due to smaller batch sizes, potential delays from customized component sourcing, and difficulties in maintaining consistent product standards. The trade-off between standardized processes and individualized offerings requires advanced data integration, flexible manufacturing systems, and robust risk management strategies to balance customization with operational efficiency.

Quality Control: Balancing Uniformity and Customization

Quality control in manufacturing requires balancing the consistency of standardization with the flexibility of hyper-personalization to meet diverse customer demands. Implementing advanced data analytics and real-time monitoring systems enhances defect detection across both uniform and customized production lines. This balance ensures high product reliability while accommodating individual specifications, minimizing errors and waste.

Case Studies: Leading Examples from the Manufacturing Industry

Case studies from the manufacturing industry reveal that standardization drives efficiency and cost reduction by streamlining production processes, exemplified by Toyota's lean manufacturing system. In contrast, hyper-personalization enhances customer satisfaction and market differentiation, as seen in BMW's customizable vehicle production that uses modular platforms. Leading manufacturers balance these approaches by adopting standardized components while enabling personalized options, achieving scalability without sacrificing individual customer preferences.

Future Trends: Integrating Standardized Processes with Personalization

Future manufacturing trends emphasize integrating standardized processes with hyper-personalization to balance efficiency and customization. Advanced technologies like AI-driven automation and modular production systems enable scalable personalization while maintaining process consistency. This hybrid approach enhances product flexibility and reduces lead times, meeting evolving consumer demands without sacrificing quality control.

Related Important Terms

Mass Customization

Mass customization in manufacturing balances standardization and hyper-personalization by using modular designs and flexible production systems to deliver individualized products at scale. This approach optimizes efficiency and reduces costs while meeting diverse customer preferences through adaptable manufacturing processes.

Modular Standardization

Modular standardization in manufacturing enables scalable production with interchangeable components, reducing costs and lead times while maintaining quality across product variations. This approach balances efficiency and customization by allowing manufacturers to configure personalized products through standardized modules without compromising on mass production benefits.

Digital Thread Personalization

Digital thread personalization integrates real-time data across the manufacturing lifecycle, enabling hyper-personalization of products without compromising the efficiencies gained from standardization; leveraging IoT sensors, AI analytics, and automated quality control systems ensures streamlined customization to meet specific customer requirements while maintaining consistent production standards. This approach enhances traceability and adaptability, reducing time-to-market and costs by harmonizing standardized processes with tailored product variations through a cohesive digital framework.

Adaptive Manufacturing

Adaptive manufacturing leverages advanced technologies such as AI, IoT, and robotics to offer hyper-personalized production without compromising efficiency or scalability inherent in standardized processes. This approach enables rapid customization of products while maintaining consistent quality and reducing lead times, transforming traditional manufacturing paradigms.

Lot Size One Production

Lot size one production challenges traditional manufacturing by enabling hyper-personalization through customizable, small-batch processes, contrasting with standardization's focus on uniform, large-scale output. This approach leverages advanced technologies like digital twins and additive manufacturing to maintain efficiency and quality while meeting individual customer specifications.

Configurable Platforms

Configurable platforms in manufacturing enable a balanced approach between standardization and hyper-personalization, allowing companies to efficiently produce customized products without sacrificing scalability or cost-effectiveness. These platforms leverage modular design, flexible automation, and advanced software integration to streamline workflows and accommodate diverse customer specifications while maintaining consistent quality and operational efficiency.

Product DNA Tagging

Product DNA tagging in manufacturing ensures consistent quality and traceability through standardization, enabling efficient mass production and streamlined supply chains. Hyper-personalization leverages digital product DNA to customize features at scale, meeting unique customer preferences without sacrificing production efficiency.

Personalized Bill of Materials (PBOM)

Personalized Bill of Materials (PBOM) enables manufacturers to tailor products at scale by integrating customer-specific components while maintaining efficient production workflows. Balancing standardization with hyper-personalization in PBOM ensures product customization without compromising cost-effectiveness or supply chain stability.

Parametric Design Automation

Parametric design automation leverages standardized algorithms and customizable parameters to streamline manufacturing processes while enabling hyper-personalization at scale. This approach balances efficiency with adaptability, reducing production costs and lead times without sacrificing tailored product specifications.

Agile Standard Operating Procedures (Agile SOPs)

Agile Standard Operating Procedures (Agile SOPs) in manufacturing balance the efficiency of standardization with the flexibility required for hyper-personalization, enabling rapid adjustments to production processes without sacrificing quality. This approach leverages iterative workflows and real-time data integration to optimize operational consistency while accommodating customized product variations and evolving customer demands.

Standardization vs Hyper-Personalization Infographic

industrydif.com

industrydif.com