Downtime in manufacturing often results in costly production halts and decreased operational efficiency. Condition-based monitoring leverages real-time data and predictive analytics to detect equipment issues before failures occur, minimizing unplanned stoppages. Implementing condition-based monitoring optimizes maintenance schedules, reduces downtime, and enhances overall equipment effectiveness.

Table of Comparison

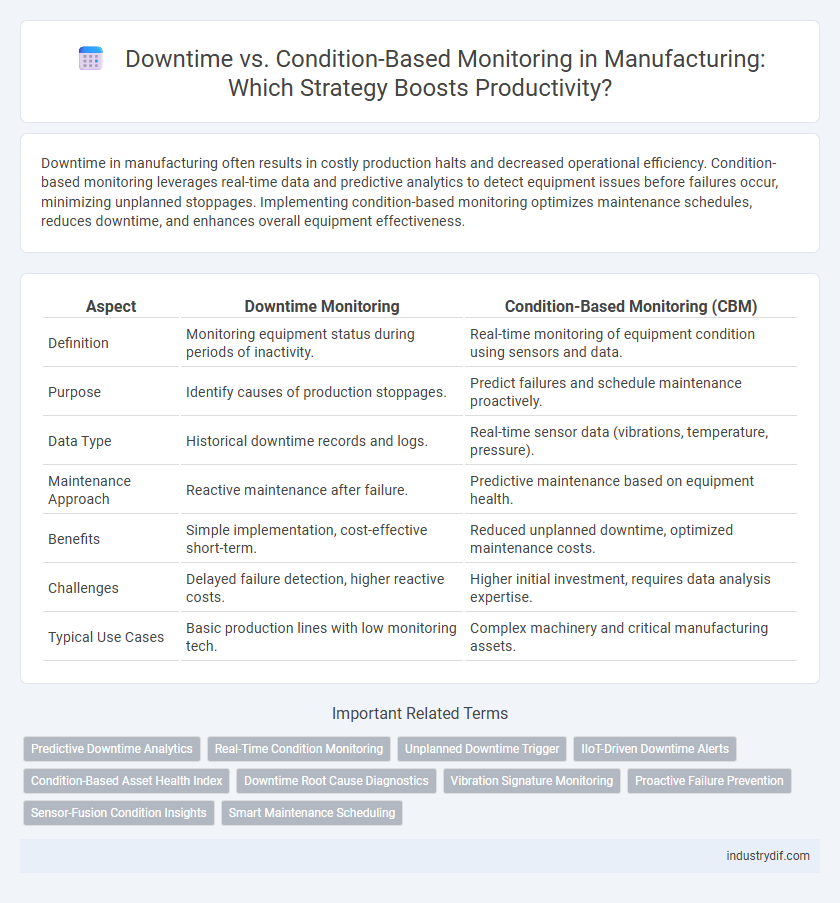

| Aspect | Downtime Monitoring | Condition-Based Monitoring (CBM) |

|---|---|---|

| Definition | Monitoring equipment status during periods of inactivity. | Real-time monitoring of equipment condition using sensors and data. |

| Purpose | Identify causes of production stoppages. | Predict failures and schedule maintenance proactively. |

| Data Type | Historical downtime records and logs. | Real-time sensor data (vibrations, temperature, pressure). |

| Maintenance Approach | Reactive maintenance after failure. | Predictive maintenance based on equipment health. |

| Benefits | Simple implementation, cost-effective short-term. | Reduced unplanned downtime, optimized maintenance costs. |

| Challenges | Delayed failure detection, higher reactive costs. | Higher initial investment, requires data analysis expertise. |

| Typical Use Cases | Basic production lines with low monitoring tech. | Complex machinery and critical manufacturing assets. |

Defining Downtime in Manufacturing

Downtime in manufacturing refers to periods when production equipment or systems are not operational, leading to halted production and reduced output. It includes planned downtime for maintenance and unexpected downtime caused by equipment failure, process disruptions, or supply chain issues. Minimizing downtime is critical for enhancing operational efficiency, reducing costs, and improving overall equipment effectiveness (OEE).

Overview of Condition-Based Monitoring

Condition-Based Monitoring (CBM) utilizes real-time data from sensors to assess equipment health and predict potential failures before downtime occurs. By continuously tracking parameters such as vibration, temperature, and pressure, CBM enables proactive maintenance, reducing unplanned interruptions and optimizing operational efficiency. This approach contrasts with traditional downtime methods by shifting maintenance from reactive to predictive strategies, ultimately enhancing asset reliability in manufacturing environments.

Causes and Consequences of Downtime

Downtime in manufacturing often results from unplanned equipment failures, operator errors, or maintenance delays, disrupting production schedules and increasing operational costs. Condition-based monitoring uses real-time data from sensors to detect anomalies early, preventing unexpected breakdowns and reducing downtime frequency. Implementing condition-based monitoring improves asset reliability, enhances productivity, and lowers maintenance expenses by addressing issues before they cause significant disruptions.

Traditional Maintenance vs Condition-Based Approaches

Traditional maintenance relies on scheduled inspections and reactive repairs, often leading to unplanned downtime and increased operational costs. Condition-based monitoring (CBM) uses real-time data from sensors to assess equipment health, enabling predictive interventions that reduce unexpected failures. Implementing CBM improves asset utilization, extends machinery lifespan, and optimizes maintenance resource allocation.

Technologies Enabling Condition-Based Monitoring

Condition-based monitoring leverages advanced sensors, IoT networks, and machine learning algorithms to detect equipment anomalies in real time, significantly reducing unplanned downtime. Technologies such as vibration analysis, thermal imaging, and acoustic sensors provide precise data for predictive maintenance, enabling timely interventions before failures occur. Integrating cloud computing and edge analytics enhances data processing speed and accuracy, maximizing equipment uptime and operational efficiency in manufacturing environments.

Key Metrics for Evaluating Downtime

Key metrics for evaluating downtime include Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and Overall Equipment Effectiveness (OEE). Condition-Based Monitoring improves these metrics by providing real-time data on equipment health, enabling predictive maintenance and reducing unexpected failures. Monitoring vibration levels, temperature, and oil quality are critical parameters that directly impact downtime reduction and operational efficiency.

Benefits of Condition-Based Monitoring in Manufacturing

Condition-based monitoring in manufacturing enhances equipment reliability by continuously tracking machine health and predicting failures before downtime occurs, reducing unplanned stoppages by up to 50%. This approach optimizes maintenance schedules, lowers repair costs by identifying issues early, and increases overall operational efficiency. Real-time data from sensors enables targeted interventions, maximizing production uptime and extending asset lifespan.

Implementation Challenges and Best Practices

Implementing condition-based monitoring (CBM) in manufacturing faces challenges such as high initial costs, integration with existing systems, and the need for skilled personnel to analyze data effectively. Overcoming these barriers requires robust sensor calibration, real-time data analytics platforms, and continuous training programs for maintenance teams. Best practices include phased deployment, integrating predictive maintenance models, and leveraging IoT connectivity to minimize unplanned downtime while optimizing asset performance.

Cost Analysis: Downtime vs Condition-Based Monitoring

Downtime in manufacturing leads to significant financial losses, including lost production, labor inefficiencies, and expedited shipping costs, often amounting to thousands of dollars per hour depending on the facility size and industry. Condition-based monitoring reduces these costs by enabling predictive maintenance, minimizing unplanned downtime through real-time data on equipment health and operational parameters. Implementing condition-based monitoring systems can result in a return on investment (ROI) within months by decreasing maintenance expenditures and increasing overall equipment effectiveness (OEE).

Future Trends in Predictive Maintenance

Future trends in predictive maintenance emphasize the shift from traditional downtime-based approaches to advanced condition-based monitoring systems that leverage real-time sensor data and machine learning algorithms. Integrating IoT-enabled devices with AI analytics enables precise fault detection and predictive insights, minimizing unplanned downtime and optimizing equipment lifespan. The convergence of digital twins, edge computing, and cloud platforms further enhances the accuracy and scalability of predictive maintenance strategies in modern manufacturing environments.

Related Important Terms

Predictive Downtime Analytics

Predictive downtime analytics leverages condition-based monitoring data such as vibration, temperature, and pressure readings to forecast equipment failures before they occur, minimizing unplanned downtime and enhancing maintenance scheduling precision. Integrating advanced sensors with machine learning algorithms enables manufacturers to shift from reactive downtime responses to proactive maintenance strategies, significantly improving operational efficiency and reducing maintenance costs.

Real-Time Condition Monitoring

Real-time condition monitoring leverages sensors and IoT technologies to continuously track equipment performance, enabling immediate detection of anomalies that reduce unplanned downtime. Implementing condition-based monitoring optimizes maintenance schedules by predicting failures before they occur, enhancing operational efficiency and minimizing production losses.

Unplanned Downtime Trigger

Unplanned downtime, often triggered by unexpected equipment failures, significantly disrupts manufacturing productivity and increases operational costs. Condition-Based Monitoring leverages real-time sensor data to predict and prevent these failures, reducing unplanned downtime by enabling timely maintenance interventions.

IIoT-Driven Downtime Alerts

IIoT-driven downtime alerts leverage real-time data from connected industrial equipment to predict and prevent unplanned stoppages, enhancing operational efficiency in manufacturing. Condition-based monitoring systems utilize sensor data to continuously assess machinery health, enabling targeted maintenance that reduces downtime and extends asset lifespan.

Condition-Based Asset Health Index

Condition-Based Asset Health Index leverages real-time sensor data and advanced analytics to predict equipment failures, minimizing unplanned downtime and optimizing maintenance schedules. This proactive approach enhances asset reliability and operational efficiency by targeting interventions based on actual machine conditions rather than fixed time intervals.

Downtime Root Cause Diagnostics

Downtime root cause diagnostics in manufacturing leverages advanced data analysis to identify failures and inefficiencies, reducing unplanned outages and improving asset reliability. Integrating condition-based monitoring with root cause diagnostics enables proactive maintenance decisions by continuously analyzing equipment health and pinpointing underlying issues before downtime occurs.

Vibration Signature Monitoring

Vibration Signature Monitoring enhances Condition-Based Monitoring by continuously analyzing machine vibrations to detect early signs of equipment failure, reducing unplanned Downtime and increasing operational efficiency. Integrating advanced sensors and predictive analytics allows manufacturers to schedule maintenance precisely, improving asset reliability and minimizing costly production interruptions.

Proactive Failure Prevention

Condition-based monitoring leverages real-time data from equipment sensors to detect early signs of wear or anomalies, enabling proactive failure prevention and reducing unplanned downtime. This approach contrasts with traditional downtime methods by minimizing maintenance costs and extending machinery lifespan through timely interventions based on actual equipment conditions.

Sensor-Fusion Condition Insights

Sensor-fusion condition insights integrate data from multiple sensors to provide real-time analysis of equipment status, significantly reducing downtime by enabling predictive maintenance. By leveraging advanced algorithms to interpret combined sensor inputs, manufacturers improve accuracy in fault detection and optimize maintenance schedules, enhancing overall operational efficiency.

Smart Maintenance Scheduling

Smart maintenance scheduling leverages condition-based monitoring by analyzing real-time equipment data to predict failures, significantly reducing unplanned downtime and optimizing resource allocation. This proactive approach enhances manufacturing efficiency, maximizes machine availability, and extends asset lifespan through timely, data-driven maintenance interventions.

Downtime vs Condition-Based Monitoring Infographic

industrydif.com

industrydif.com