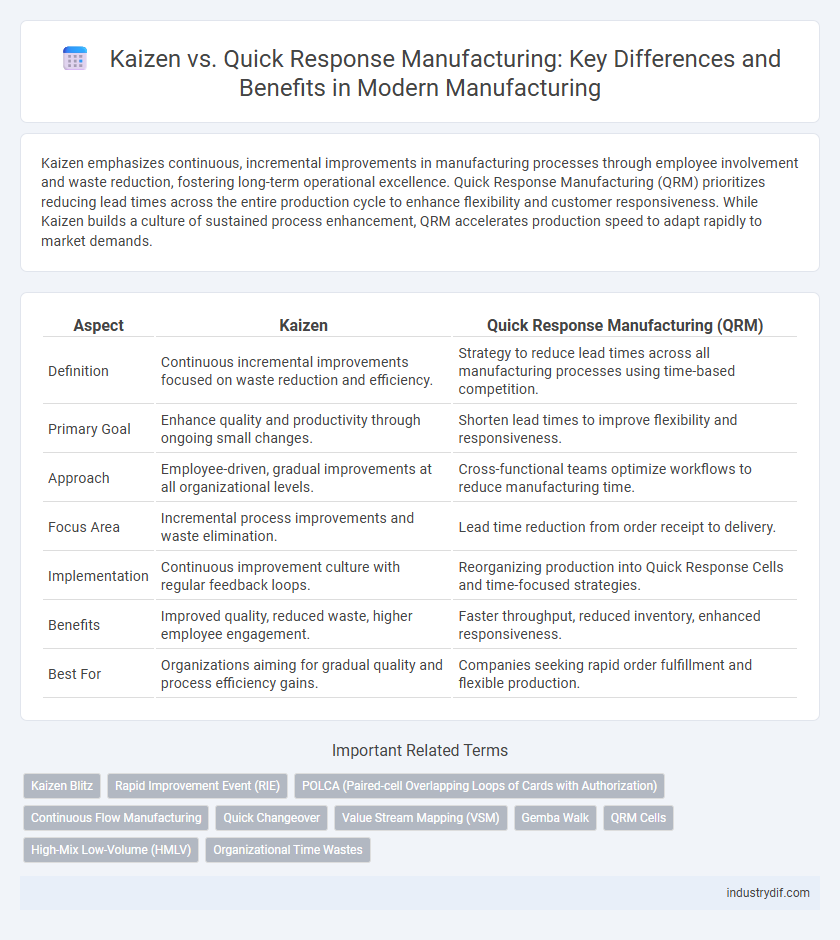

Kaizen emphasizes continuous, incremental improvements in manufacturing processes through employee involvement and waste reduction, fostering long-term operational excellence. Quick Response Manufacturing (QRM) prioritizes reducing lead times across the entire production cycle to enhance flexibility and customer responsiveness. While Kaizen builds a culture of sustained process enhancement, QRM accelerates production speed to adapt rapidly to market demands.

Table of Comparison

| Aspect | Kaizen | Quick Response Manufacturing (QRM) |

|---|---|---|

| Definition | Continuous incremental improvements focused on waste reduction and efficiency. | Strategy to reduce lead times across all manufacturing processes using time-based competition. |

| Primary Goal | Enhance quality and productivity through ongoing small changes. | Shorten lead times to improve flexibility and responsiveness. |

| Approach | Employee-driven, gradual improvements at all organizational levels. | Cross-functional teams optimize workflows to reduce manufacturing time. |

| Focus Area | Incremental process improvements and waste elimination. | Lead time reduction from order receipt to delivery. |

| Implementation | Continuous improvement culture with regular feedback loops. | Reorganizing production into Quick Response Cells and time-focused strategies. |

| Benefits | Improved quality, reduced waste, higher employee engagement. | Faster throughput, reduced inventory, enhanced responsiveness. |

| Best For | Organizations aiming for gradual quality and process efficiency gains. | Companies seeking rapid order fulfillment and flexible production. |

Introduction to Kaizen and Quick Response Manufacturing

Kaizen is a continuous improvement methodology originating from Japan that emphasizes incremental changes to enhance manufacturing processes, productivity, and quality. Quick Response Manufacturing (QRM) focuses on reducing lead times across all phases of production to improve flexibility and responsiveness to customer demands. Both methodologies aim to optimize manufacturing efficiency by minimizing waste and accelerating production cycles.

Core Principles of Kaizen

Kaizen centers on continuous, incremental improvements driven by employee involvement and standardized processes to enhance efficiency and reduce waste. It emphasizes a culture of ongoing feedback, teamwork, and problem-solving at every organizational level to optimize manufacturing operations. This contrasts with Quick Response Manufacturing, which prioritizes speed and flexibility to meet rapid market changes.

Foundation of Quick Response Manufacturing

Quick Response Manufacturing (QRM) is founded on reducing lead times across all phases of production to enhance flexibility and responsiveness in manufacturing systems. Unlike Kaizen, which emphasizes continuous incremental improvements, QRM targets systemic time-based improvements by restructuring organizational design and cross-functional teams to minimize delays. This foundation allows manufacturers to rapidly respond to customer demands, reduce work-in-process inventory, and increase overall efficiency in dynamic market environments.

Key Differences Between Kaizen and QRM

Kaizen emphasizes continuous, incremental improvements in all areas of manufacturing, fostering a culture of sustained employee involvement and waste reduction. Quick Response Manufacturing (QRM) targets lead time reduction by reorganizing production and improving responsiveness, often through cellular manufacturing and cross-functional teams. While Kaizen focuses on ongoing small enhancements for quality and efficiency, QRM prioritizes speed and agility to rapidly adapt to customer demands.

Process Improvement Approaches: Continuous vs. Responsive

Kaizen emphasizes continuous process improvement through incremental changes and employee involvement to enhance efficiency and quality over time. Quick Response Manufacturing (QRM) focuses on reducing lead times and increasing responsiveness by streamlining processes and prioritizing rapid decision-making. While Kaizen fosters gradual, sustained enhancements, QRM targets immediate, flexible adjustments to meet dynamic market demands.

Impact on Lead Time and Productivity

Kaizen emphasizes continuous incremental improvements that gradually reduce lead time by identifying and eliminating waste in manufacturing processes, resulting in sustained productivity gains. Quick Response Manufacturing (QRM) focuses on drastically shortening lead times by accelerating communication and decision-making, which enhances responsiveness and boosts productivity in high-mix, low-volume production environments. While Kaizen fosters long-term efficiency, QRM delivers rapid lead time reductions, making both methodologies complementary for optimizing manufacturing performance.

Employee Involvement in Kaizen vs. QRM

Employee involvement in Kaizen centers on continuous, incremental improvements driven by frontline workers who identify inefficiencies and propose solutions during regular, team-based activities. Quick Response Manufacturing (QRM) emphasizes cross-functional collaboration with a focus on reducing lead times through rapid decision-making and flexible workforce deployment but involves employees primarily in time-sensitive problem-solving rather than ongoing process refinement. Both approaches leverage employee input, but Kaizen fosters a culture of sustained participation, whereas QRM targets agile responsiveness to dynamic production demands.

Industry Applications and Case Studies

Kaizen emphasizes continuous, incremental improvements in manufacturing processes, widely adopted in automotive and electronics industries to enhance efficiency and reduce waste. Quick Response Manufacturing (QRM) focuses on minimizing lead times across all manufacturing operations, proving effective in custom job shops and make-to-order industries such as aerospace and medical devices. Case studies reveal Kaizen's success in Toyota's assembly lines through steady quality improvements, while QRM drives agility and faster delivery in Timken's precision component production.

Implementation Challenges and Solutions

Kaizen implementation often faces challenges such as employee resistance to continuous change and the need for sustained cultural shifts, which can be addressed through ongoing training and leadership commitment. Quick Response Manufacturing (QRM) struggles with integrating cross-functional teams and redesigning workflows, requiring robust communication platforms and incremental process adjustments to ensure responsiveness. Both methodologies demand tailored change management strategies to overcome operational inertia and achieve efficient, adaptive production systems.

Choosing the Right Strategy for Your Manufacturing Needs

Kaizen emphasizes continuous, incremental improvements to enhance efficiency and reduce waste in manufacturing processes, making it ideal for organizations seeking long-term, sustainable growth. Quick Response Manufacturing focuses on agility and rapid production to meet fluctuating customer demands, best suited for industries requiring high flexibility and fast turnaround times. Selecting the right strategy depends on the specific goals, production complexity, and market responsiveness of your manufacturing operation.

Related Important Terms

Kaizen Blitz

Kaizen Blitz emphasizes rapid, focused improvements within manufacturing processes by engaging cross-functional teams in short, intensive problem-solving events that identify and eliminate inefficiencies. Quick Response Manufacturing prioritizes reducing lead times through synchronized production and supply chain coordination but lacks the deep, immediate process optimization driven by Kaizen Blitz activities.

Rapid Improvement Event (RIE)

Rapid Improvement Events (RIE) in Kaizen emphasize continuous, incremental enhancements through focused, short-term projects engaging cross-functional teams to systematically eliminate waste and improve processes. Quick Response Manufacturing leverages RIE to accelerate cycle times and increase flexibility, enabling faster adaptation to customer demands while maintaining quality and reducing inventory.

POLCA (Paired-cell Overlapping Loops of Cards with Authorization)

Kaizen emphasizes continuous incremental improvements in manufacturing processes, fostering waste reduction and efficiency through employee involvement, while Quick Response Manufacturing (QRM) targets lead time reduction by focusing on the entire production system. POLCA, a card-based production control system used within QRM, optimizes flow by regulating work-in-progress between cells, minimizing bottlenecks and enhancing responsiveness in custom and small-batch manufacturing environments.

Continuous Flow Manufacturing

Kaizen emphasizes incremental, continuous improvement through employee involvement and standardized work, fostering a culture of ongoing efficiency gains in Continuous Flow Manufacturing. Quick Response Manufacturing prioritizes rapid production cycle times by minimizing lead times and inventory, enabling swift adaptation to customer demand within Continuous Flow processes.

Quick Changeover

Quick Response Manufacturing (QRM) emphasizes reducing lead times across all manufacturing processes, with quick changeover techniques minimizing equipment downtime to accelerate production cycles. Kaizen focuses on continuous incremental improvements, but QRM's rapid changeover strategies enable more flexible and responsive manufacturing systems tailored to dynamic customer demands.

Value Stream Mapping (VSM)

Kaizen emphasizes continuous, incremental improvements by analyzing each step in the value stream to eliminate waste and enhance efficiency, leveraging Value Stream Mapping (VSM) as a core tool for identifying bottlenecks. Quick Response Manufacturing (QRM) uses VSM to accelerate lead times across the entire production system, focusing on reducing queue times and improving responsiveness to customer demand.

Gemba Walk

Kaizen emphasizes continuous improvement through Gemba Walks, where managers observe and engage directly with shop floor activities to identify inefficiencies and empower workers. Quick Response Manufacturing prioritizes rapid changeover and agile production but integrates Gemba Walks primarily to swiftly diagnose bottlenecks and accelerate problem-solving within lean workflows.

QRM Cells

Quick Response Manufacturing (QRM) cells prioritize reducing lead times by organizing cross-functional teams around specific product families to accelerate production and improve responsiveness. Unlike Kaizen's continuous incremental improvements, QRM cells implement rapid process changes that significantly cut system-wide delays in low-volume, high-mix manufacturing environments.

High-Mix Low-Volume (HMLV)

Kaizen emphasizes continuous incremental improvements in processes, ideal for High-Mix Low-Volume (HMLV) manufacturing by enhancing flexibility and reducing waste systematically. Quick Response Manufacturing (QRM) accelerates lead times through organization-wide strategies, making it highly effective for HMLV environments where rapid adaptation to changing customer demands is crucial.

Organizational Time Wastes

Kaizen minimizes organizational time wastes by fostering continuous, incremental improvements that streamline workflows and eliminate inefficiencies through employee-driven problem solving. Quick Response Manufacturing (QRM) targets organizational time wastes by drastically reducing lead times and production delays via cross-functional teams and real-time decision-making in the shop floor environment.

Kaizen vs Quick Response Manufacturing Infographic

industrydif.com

industrydif.com