Six Sigma emphasizes reducing defects and variability in manufacturing processes through data-driven statistical analysis, improving quality and efficiency. Digital Twin technology creates virtual replicas of physical assets to simulate, predict, and optimize production in real-time, enhancing decision-making and operational agility. Combining Six Sigma's process precision with Digital Twin's dynamic modeling enables manufacturers to achieve superior performance and innovation.

Table of Comparison

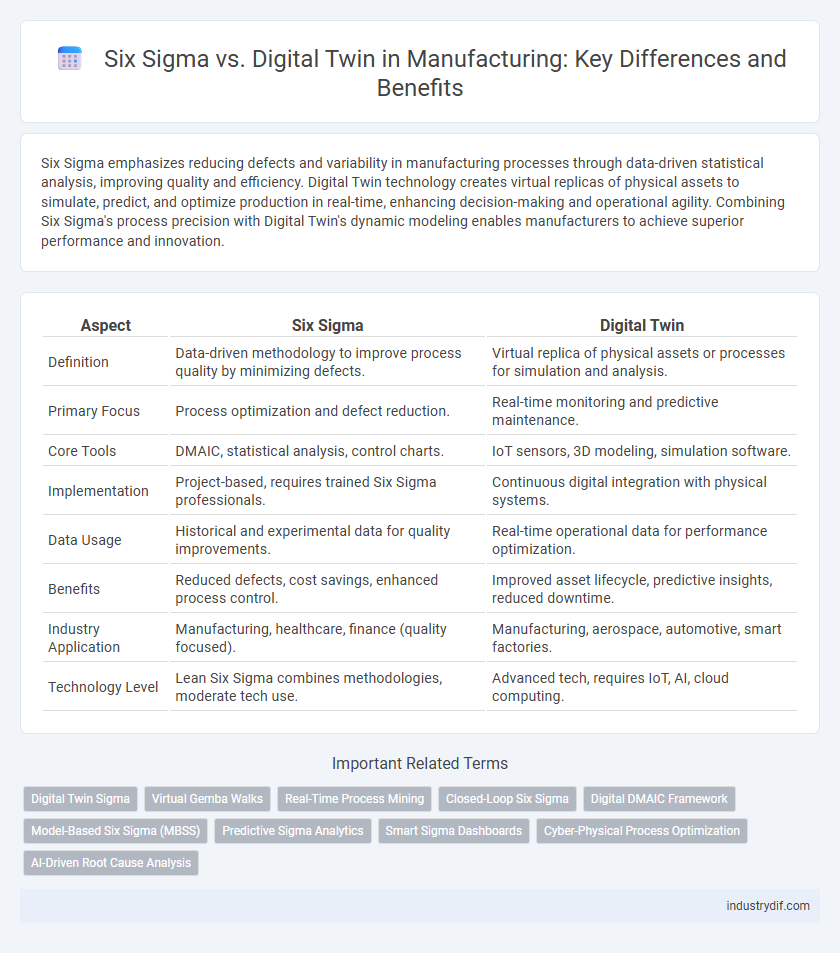

| Aspect | Six Sigma | Digital Twin |

|---|---|---|

| Definition | Data-driven methodology to improve process quality by minimizing defects. | Virtual replica of physical assets or processes for simulation and analysis. |

| Primary Focus | Process optimization and defect reduction. | Real-time monitoring and predictive maintenance. |

| Core Tools | DMAIC, statistical analysis, control charts. | IoT sensors, 3D modeling, simulation software. |

| Implementation | Project-based, requires trained Six Sigma professionals. | Continuous digital integration with physical systems. |

| Data Usage | Historical and experimental data for quality improvements. | Real-time operational data for performance optimization. |

| Benefits | Reduced defects, cost savings, enhanced process control. | Improved asset lifecycle, predictive insights, reduced downtime. |

| Industry Application | Manufacturing, healthcare, finance (quality focused). | Manufacturing, aerospace, automotive, smart factories. |

| Technology Level | Lean Six Sigma combines methodologies, moderate tech use. | Advanced tech, requires IoT, AI, cloud computing. |

Introduction to Six Sigma and Digital Twin in Manufacturing

Six Sigma in manufacturing is a data-driven methodology focused on reducing defects and improving process quality by identifying and eliminating variability through statistical analysis. Digital Twin technology creates a virtual replica of physical manufacturing processes, enabling real-time monitoring, simulation, and optimization of production performance. Combining Six Sigma with Digital Twin allows manufacturers to enhance process control and predictive maintenance, resulting in increased efficiency and reduced operational costs.

Core Principles of Six Sigma

Six Sigma centers on reducing process variation through a data-driven approach, emphasizing DMAIC methodology--Define, Measure, Analyze, Improve, and Control--to enhance quality and efficiency in manufacturing. It relies on statistical tools and Six Sigma belts certification levels to systematically eliminate defects and optimize production processes. Unlike Digital Twin technology, which creates virtual replicas for real-time simulation and predictive maintenance, Six Sigma's core principle is focused on continuous process improvement through rigorous measurement and analysis.

Fundamentals of Digital Twin Technology

Digital Twin technology in manufacturing creates precise virtual replicas of physical assets, processes, or systems to enable real-time monitoring, simulation, and predictive analytics. Unlike Six Sigma which focuses on reducing defects through statistical methods, Digital Twins integrate IoT sensors, AI, and data analytics to optimize operations continuously. This fundamental shift enhances proactive maintenance, reduces downtime, and accelerates decision-making by providing a dynamic, data-driven model of manufacturing environments.

Key Differences Between Six Sigma and Digital Twin

Six Sigma is a data-driven methodology aimed at reducing defects and improving process quality through statistical analysis and DMAIC phases, while Digital Twin technology creates a virtual replica of physical assets or processes for real-time monitoring and simulation. Six Sigma emphasizes process improvement by analyzing historical data to identify root causes of inefficiencies, whereas Digital Twin leverages sensors and IoT data to provide dynamic insights and predictive maintenance. Key differences include Six Sigma's focus on quality control and structured problem-solving contrasted with Digital Twin's emphasis on continuous virtual modeling and real-time operational optimization.

Applications of Six Sigma in Manufacturing Processes

Six Sigma is widely applied in manufacturing to reduce process variability and defects, enhancing product quality and operational efficiency through data-driven decision making and statistical analysis. Key applications include optimizing production workflows, minimizing waste, and improving equipment reliability by systematically identifying root causes of defects. Integrating Six Sigma methodologies streamlines manufacturing processes, leading to consistent output and increased customer satisfaction.

Real-Time Optimization with Digital Twin

Real-time optimization in manufacturing leverages Digital Twin technology to create dynamic, virtual replicas of physical production systems that enable continuous monitoring and predictive adjustments. Unlike Six Sigma, which primarily focuses on statistical process improvement and defect reduction through historical data analysis, Digital Twins provide live data integration and simulation for proactive decision-making. This real-time feedback loop enhances operational efficiency, reduces downtime, and accelerates innovation by dynamically adapting processes based on current conditions.

Integrating Six Sigma and Digital Twin for Process Excellence

Integrating Six Sigma with Digital Twin technology enhances process excellence by combining data-driven quality management with real-time simulation and analytics. Six Sigma's DMAIC methodology benefits from Digital Twin's capability to model and predict process variations, enabling proactive identification of defects and continuous improvement. This integration accelerates problem-solving, reduces downtime, and optimizes manufacturing efficiency through precise process control and virtual experimentation.

Benefits and Limitations of Six Sigma

Six Sigma enhances manufacturing quality by reducing defects through data-driven methodologies and rigorous statistical analysis, resulting in cost savings and improved customer satisfaction. Its limitations include lengthy implementation timelines and reliance on extensive employee training, which can hinder agility in fast-paced production environments. While Six Sigma excels in process optimization, it may struggle to adapt to real-time changes compared to more dynamic technologies like Digital Twin simulations.

Advantages and Challenges of Digital Twin

Digital Twin technology offers real-time simulation and predictive analytics, enabling manufacturers to optimize processes, reduce downtime, and enhance product quality with precise virtual models. Its advantages include improved decision-making through data integration from IoT sensors and advanced analytics, allowing early detection of potential failures and cost savings in maintenance. Challenges involve high implementation costs, complex data management, and the need for skilled personnel to maintain and interpret the digital models effectively in a dynamic manufacturing environment.

Future Trends: Synergies Between Six Sigma and Digital Twin

Future trends in manufacturing highlight the powerful synergies between Six Sigma and Digital Twin technologies, enabling real-time data analytics for enhanced process optimization. Integrating Digital Twin simulations with Six Sigma's DMAIC methodology drives predictive quality control and reduces defects through virtual process modeling. This convergence supports continuous improvement initiatives, accelerates decision-making, and fosters smarter, data-driven manufacturing environments.

Related Important Terms

Digital Twin Sigma

Digital Twin Sigma integrates Six Sigma methodologies with advanced digital twin technology to enhance manufacturing process optimization and quality control. By using real-time virtual simulations, Digital Twin Sigma enables predictive analytics and continuous improvement, reducing defects and operational costs more effectively than traditional Six Sigma alone.

Virtual Gemba Walks

Six Sigma enhances manufacturing quality through data-driven problem solving, while Digital Twin technology enables virtual Gemba walks by providing real-time, immersive simulations of the production floor. Virtual Gemba walks foster proactive identification of inefficiencies and process improvements without physical presence, combining Six Sigma's analytical rigor with Digital Twin's dynamic visualization for optimized operational excellence.

Real-Time Process Mining

Six Sigma enhances manufacturing quality by reducing defects through data-driven statistical analysis, while Digital Twin technology leverages real-time process mining to create dynamic virtual models that monitor and optimize production workflows instantly. Real-time process mining enables continuous data extraction and analysis from digital footprints, providing actionable insights for operational efficiency and predictive maintenance in manufacturing environments.

Closed-Loop Six Sigma

Closed-Loop Six Sigma integrates real-time data analytics and digital twin simulations to continuously monitor, analyze, and optimize manufacturing processes, enhancing defect reduction and operational efficiency. Leveraging digital twin technology enables rapid scenario testing and feedback, ensuring closed-loop control and sustained quality improvements across production cycles.

Digital DMAIC Framework

Digital DMAIC Framework integrates Six Sigma methodologies with digital twin technology to enhance process optimization in manufacturing. By utilizing real-time data and virtual simulations, it enables precise identification and rectification of defects, leading to improved quality and reduced cycle times.

Model-Based Six Sigma (MBSS)

Model-Based Six Sigma (MBSS) integrates Six Sigma's statistical rigor with digital twin technology to enhance process optimization and defect reduction in manufacturing. By utilizing digital twins to simulate and analyze processes in real-time, MBSS enables precise identification of variability and improved decision-making, driving higher-quality product outcomes and operational efficiency.

Predictive Sigma Analytics

Predictive Sigma Analytics leverages Six Sigma methodologies integrated with Digital Twin technology to enhance manufacturing process optimization by simulating real-time system behavior and forecasting defects. This combination enables precise data-driven decision-making that minimizes variability, reduces waste, and improves overall product quality and operational efficiency.

Smart Sigma Dashboards

Smart Sigma Dashboards integrate Six Sigma methodologies with Digital Twin technology, enabling real-time data visualization and predictive analytics for enhanced process optimization. These dashboards provide dynamic insights into quality metrics and operational performance, driving informed decision-making and continuous improvement in manufacturing systems.

Cyber-Physical Process Optimization

Six Sigma leverages statistical methods to reduce process variation and enhance quality control in manufacturing, while Digital Twin technology creates real-time virtual replicas of physical assets to enable predictive analytics and dynamic process optimization. Integrating Cyber-Physical Systems through Digital Twins allows continuous monitoring and simulation of manufacturing processes, surpassing traditional Six Sigma approaches by enabling proactive and adaptive improvements.

AI-Driven Root Cause Analysis

Six Sigma leverages statistical analysis and process improvement techniques to identify and eliminate defects, while Digital Twin technology integrates AI-driven root cause analysis by simulating real-time operations and predicting system failures through machine learning algorithms. AI-enabled Digital Twins provide dynamic insights into manufacturing processes, enabling faster identification of underlying issues and proactive decision-making compared to the traditionally data-intensive Six Sigma methodology.

Six Sigma vs Digital Twin Infographic

industrydif.com

industrydif.com