Agile manufacturing emphasizes rapid responsiveness to market changes through flexible production processes and adaptive workforce strategies. Resilient manufacturing prioritizes robustness against disruptions by incorporating risk management, redundancy, and robust supply chain design. Combining agility with resilience enables manufacturers to swiftly adapt to evolving demands while maintaining operational continuity under adverse conditions.

Table of Comparison

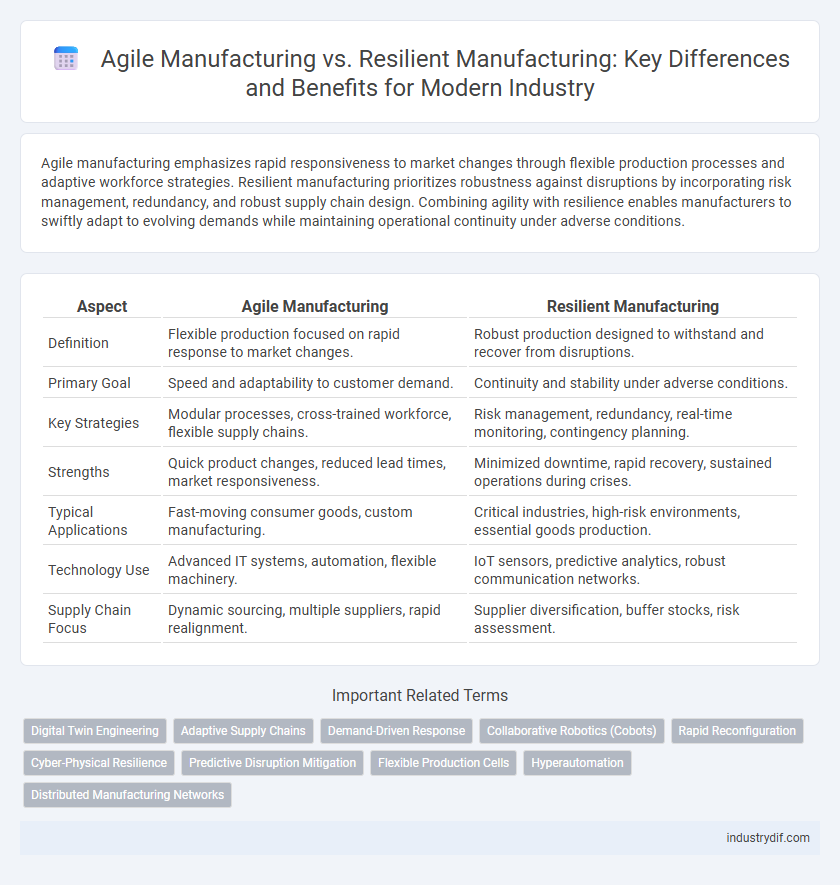

| Aspect | Agile Manufacturing | Resilient Manufacturing |

|---|---|---|

| Definition | Flexible production focused on rapid response to market changes. | Robust production designed to withstand and recover from disruptions. |

| Primary Goal | Speed and adaptability to customer demand. | Continuity and stability under adverse conditions. |

| Key Strategies | Modular processes, cross-trained workforce, flexible supply chains. | Risk management, redundancy, real-time monitoring, contingency planning. |

| Strengths | Quick product changes, reduced lead times, market responsiveness. | Minimized downtime, rapid recovery, sustained operations during crises. |

| Typical Applications | Fast-moving consumer goods, custom manufacturing. | Critical industries, high-risk environments, essential goods production. |

| Technology Use | Advanced IT systems, automation, flexible machinery. | IoT sensors, predictive analytics, robust communication networks. |

| Supply Chain Focus | Dynamic sourcing, multiple suppliers, rapid realignment. | Supplier diversification, buffer stocks, risk assessment. |

Introduction to Agile and Resilient Manufacturing

Agile manufacturing emphasizes rapid responsiveness and flexibility to market changes by leveraging modular processes and cross-functional teams. Resilient manufacturing focuses on the ability to withstand and recover from disruptions through robust supply chains and adaptive risk management strategies. Both methodologies aim to enhance operational efficiency, but agile manufacturing prioritizes speed, while resilient manufacturing prioritizes durability.

Defining Agile Manufacturing: Principles and Practices

Agile manufacturing emphasizes flexibility and rapid responsiveness to market changes by integrating principles such as modular product design, cross-functional teams, and real-time information sharing. This approach relies on just-in-time production, lean inventory management, and adaptive supply chains to minimize waste and accelerate product delivery. Core practices include collaborative decision-making, continuous improvement cycles, and leveraging advanced technologies like IoT and AI for dynamic resource allocation and process optimization.

Understanding Resilient Manufacturing: Core Concepts

Resilient manufacturing emphasizes adaptability and rapid recovery from disruptions by integrating robust supply chain risk management and flexible production systems. Core concepts include redundancy, real-time data analytics, and decentralized decision-making to maintain continuous operations under uncertain conditions. This approach contrasts with agile manufacturing, which primarily focuses on speed and customization, by prioritizing system robustness and long-term stability.

Key Differences Between Agile and Resilient Manufacturing

Agile manufacturing emphasizes rapid responsiveness and flexibility to changing customer demands and market conditions, leveraging modular processes and cross-functional teams. Resilient manufacturing prioritizes robustness and recovery capability in the face of disruptions such as supply chain interruptions or equipment failures, focusing on risk management and redundancy. Key differences lie in agility's speed and adaptability versus resilience's stability and continuity under adverse conditions.

Benefits of Agile Manufacturing Strategies

Agile manufacturing strategies enhance production flexibility, enabling companies to respond quickly to market changes and customer demands, resulting in reduced lead times and increased customer satisfaction. This approach leverages cross-functional teams and adaptive processes to optimize resource utilization and minimize waste. Companies adopting agile methodologies experience improved innovation cycles and a competitive advantage in rapidly evolving markets.

Advantages of Resilient Manufacturing Approaches

Resilient manufacturing approaches enhance supply chain stability by quickly adapting to disruptions such as material shortages or demand fluctuations, reducing downtime and financial losses. These approaches prioritize flexibility and redundancy, enabling rapid recovery and continuous production under unpredictable conditions. Emphasizing risk management and real-time data analytics, resilient manufacturing helps maintain product quality and customer satisfaction during market volatility.

Challenges in Implementing Agile Manufacturing

Implementing Agile Manufacturing faces challenges such as high initial investment costs in advanced technologies and the need for workforce upskilling to manage rapidly changing production processes. Integrating flexible supply chains while maintaining quality and efficiency demands significant coordination among suppliers and internal teams. Resistance to change and the complexity of adapting legacy systems further complicate the transition from traditional to agile manufacturing environments.

Overcoming Obstacles in Resilient Manufacturing

Resilient manufacturing overcomes obstacles by emphasizing adaptability and rapid recovery from disruptions such as supply chain interruptions or equipment failures. Unlike agile manufacturing, which focuses on flexibility and speed in production processes, resilient manufacturing incorporates robust risk management strategies and redundancy to maintain continuous operations under stress. Implementing advanced data analytics and real-time monitoring systems enhances a facility's ability to detect issues early and respond effectively, ensuring sustained productivity amidst uncertainty.

Case Studies: Agile vs. Resilient Manufacturing in Action

Case studies comparing Agile and Resilient Manufacturing reveal distinct advantages: Agile Manufacturing excels in responsiveness to rapid market changes by leveraging modular production lines and real-time data analytics, exemplified by automotive firms rapidly iterating prototypes. Resilient Manufacturing emphasizes robustness against disruptions such as supply chain shocks and natural disasters, as demonstrated by aerospace companies implementing diversified supplier networks and redundancies to maintain production continuity. Corporations adopting hybrid strategies report enhanced competitiveness by balancing agility's speed with resilience's durability in complex manufacturing environments.

Future Trends: Integrating Agility and Resilience in Manufacturing

Future trends in manufacturing emphasize integrating agility and resilience to enhance responsiveness and robustness against disruptions. Agile manufacturing leverages rapid reconfiguration and lean processes, while resilient manufacturing focuses on adaptive recovery and risk management. Combining these approaches enables manufacturers to optimize supply chain flexibility, minimize downtime, and sustain competitive advantage in dynamic markets.

Related Important Terms

Digital Twin Engineering

Agile manufacturing leverages digital twin engineering to simulate rapid design iterations and optimize production workflows, enabling swift adaptation to market changes. Resilient manufacturing uses digital twins to predict system disruptions and enhance recovery strategies, ensuring continuous operation amid supply chain uncertainties.

Adaptive Supply Chains

Agile manufacturing emphasizes rapid responsiveness and flexibility through adaptive supply chains that optimize inventory levels and minimize lead times. Resilient manufacturing builds on this by incorporating risk management and redundancy in supply networks to absorb disruptions while maintaining operational continuity.

Demand-Driven Response

Agile manufacturing emphasizes rapid adaptation to changing customer demands through flexible processes and real-time data integration, enabling swift product customization and market responsiveness. Resilient manufacturing prioritizes maintaining continuous operations under disruptions by incorporating robust supply chain risk management and redundancy, ensuring sustained demand-driven production despite unforeseen challenges.

Collaborative Robotics (Cobots)

Collaborative robotics (cobots) enhance agile manufacturing by enabling rapid reconfiguration of production lines through flexible, human-robot interaction, which accelerates responsiveness to market changes. In resilient manufacturing, cobots contribute to operational continuity by autonomously performing repetitive tasks during disruptions, ensuring consistent output despite supply chain or workforce challenges.

Rapid Reconfiguration

Agile manufacturing emphasizes rapid reconfiguration by enabling flexible production processes that quickly adapt to customer demands and market changes. Resilient manufacturing incorporates this rapid reconfiguration ability while also focusing on maintaining operational continuity during disruptions to minimize downtime and supply chain vulnerabilities.

Cyber-Physical Resilience

Cyber-physical resilience in manufacturing integrates real-time data analytics, IoT sensors, and adaptive control systems to ensure both agile manufacturing's rapid responsiveness and resilient manufacturing's robust recovery from disruptions. This synergy enhances operational continuity by enabling dynamic reconfiguration of production lines and proactive threat detection within smart factory environments.

Predictive Disruption Mitigation

Agile manufacturing emphasizes rapid adaptation to market changes through flexible processes and modular production systems, while resilient manufacturing focuses on maintaining operations during disruptions by leveraging predictive analytics and real-time data monitoring. Predictive disruption mitigation in resilient manufacturing employs advanced machine learning algorithms and IoT sensors to anticipate supply chain interruptions and equipment failures, enabling preemptive responses that minimize downtime and sustain productivity.

Flexible Production Cells

Flexible production cells in agile manufacturing prioritize rapid responsiveness and customization, enabling quick adaptation to changing market demands through modular equipment and cross-trained labor. In contrast, resilient manufacturing emphasizes robustness and recovery, designing flexible cells to maintain continuous operation despite disruptions, ensuring durability and sustained output in volatile environments.

Hyperautomation

Hyperautomation enhances Agile Manufacturing by integrating AI, machine learning, and robotics to accelerate production cycles and improve flexibility in response to market changes. In Resilient Manufacturing, hyperautomation strengthens system robustness by enabling predictive maintenance and real-time supply chain adjustments, minimizing downtime and operational risks.

Distributed Manufacturing Networks

Distributed manufacturing networks enhance agile manufacturing by enabling rapid adaptation to market changes through decentralized production sites. These networks also strengthen resilient manufacturing by distributing risk, ensuring continuity and recovery during supply chain disruptions.

Agile Manufacturing vs Resilient Manufacturing Infographic

industrydif.com

industrydif.com