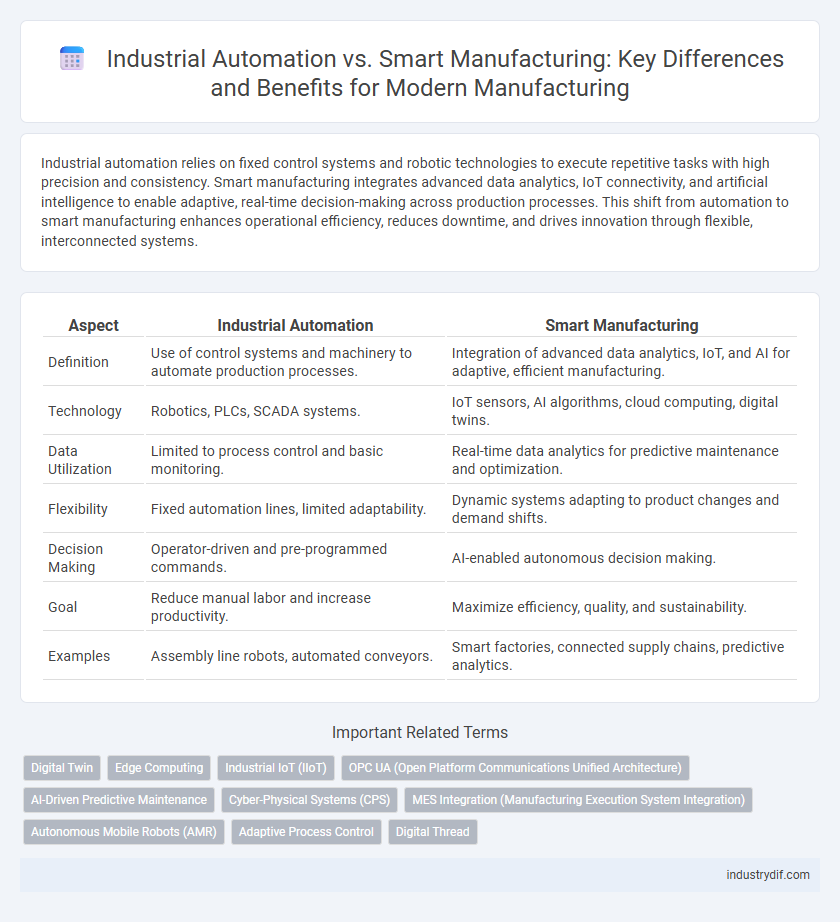

Industrial automation relies on fixed control systems and robotic technologies to execute repetitive tasks with high precision and consistency. Smart manufacturing integrates advanced data analytics, IoT connectivity, and artificial intelligence to enable adaptive, real-time decision-making across production processes. This shift from automation to smart manufacturing enhances operational efficiency, reduces downtime, and drives innovation through flexible, interconnected systems.

Table of Comparison

| Aspect | Industrial Automation | Smart Manufacturing |

|---|---|---|

| Definition | Use of control systems and machinery to automate production processes. | Integration of advanced data analytics, IoT, and AI for adaptive, efficient manufacturing. |

| Technology | Robotics, PLCs, SCADA systems. | IoT sensors, AI algorithms, cloud computing, digital twins. |

| Data Utilization | Limited to process control and basic monitoring. | Real-time data analytics for predictive maintenance and optimization. |

| Flexibility | Fixed automation lines, limited adaptability. | Dynamic systems adapting to product changes and demand shifts. |

| Decision Making | Operator-driven and pre-programmed commands. | AI-enabled autonomous decision making. |

| Goal | Reduce manual labor and increase productivity. | Maximize efficiency, quality, and sustainability. |

| Examples | Assembly line robots, automated conveyors. | Smart factories, connected supply chains, predictive analytics. |

Defining Industrial Automation

Industrial automation involves using control systems such as robots, programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) systems to operate machinery and processes with minimal human intervention. This technology enables consistent production quality, increased efficiency, and reduced operational costs by automating repetitive and complex tasks. Industrial automation primarily focuses on mechanizing production lines, whereas smart manufacturing integrates advanced data analytics, IoT, and AI for real-time decision-making and adaptive operations.

Understanding Smart Manufacturing

Smart manufacturing integrates advanced data analytics, IoT sensors, and AI algorithms to optimize production processes, reduce downtime, and enhance quality control beyond traditional industrial automation capabilities. Unlike conventional industrial automation that primarily automates repetitive tasks, smart manufacturing enables real-time decision-making and adaptive systems through interconnected cyber-physical systems. This shift leads to increased flexibility, predictive maintenance, and efficient resource management aligned with Industry 4.0 standards.

Key Technologies in Industrial Automation

Key technologies in industrial automation include programmable logic controllers (PLCs), human-machine interfaces (HMIs), robotics, and sensors that facilitate real-time data acquisition and control processes. These technologies enable automated production lines, reducing human intervention and increasing precision in manufacturing operations. Integration with cyber-physical systems and industrial Internet of Things (IIoT) platforms drives efficiency and predictive maintenance in modern industrial automation setups.

Core Components of Smart Manufacturing

Smart manufacturing integrates advanced technologies such as IoT sensors, AI-driven analytics, and cyber-physical systems to enhance productivity and flexibility. Core components include real-time data acquisition, automated decision-making processes, and interconnected machinery for seamless communication. These elements enable adaptive production lines and predictive maintenance, surpassing traditional industrial automation capabilities.

Evolution from Automation to Smart Manufacturing

Industrial automation primarily involves the use of control systems and machinery to perform manufacturing processes with minimal human intervention, focusing on efficiency and precision. Smart manufacturing evolves this concept by integrating Internet of Things (IoT), artificial intelligence (AI), and data analytics to create interconnected, adaptive production systems that optimize performance in real-time. This evolution enhances flexibility, predictive maintenance, and quality control, driving Industry 4.0 transformation across global manufacturing sectors.

Efficiency and Productivity Comparison

Industrial automation relies on fixed control systems to enhance efficiency by automating repetitive tasks, leading to consistent productivity improvements within predefined parameters. Smart manufacturing integrates IoT, AI, and real-time data analytics to optimize processes dynamically, significantly boosting efficiency through adaptive decision-making and predictive maintenance. The shift from industrial automation to smart manufacturing results in superior productivity gains by enabling more flexible, data-driven operations and reducing downtime.

Integration of IoT and AI

Industrial automation primarily relies on predefined control systems and robotics to streamline manufacturing processes, whereas smart manufacturing integrates IoT sensors and AI algorithms for real-time data analysis and adaptive decision-making. The integration of IoT enables continuous monitoring of equipment and environmental conditions, while AI-driven predictive maintenance enhances operational efficiency and reduces downtime. This convergence facilitates a more connected, intelligent production ecosystem that optimizes resource use and enhances product quality.

Data Management and Analytics

Industrial automation primarily focuses on the control and machinery processes using programmable logic controllers and SCADA systems to optimize production efficiency. Smart manufacturing integrates advanced data management and analytics platforms, leveraging IoT sensors and AI algorithms to enable real-time decision-making and predictive maintenance. This data-driven approach enhances operational agility, quality control, and overall equipment effectiveness beyond traditional automation capabilities.

Challenges and Barriers in Adoption

Industrial automation faces challenges such as high initial capital investment, integration complexities with legacy systems, and workforce skill gaps, which hinder seamless adoption. Smart manufacturing encounters barriers including cybersecurity risks, data interoperability issues, and the need for advanced analytics capabilities to fully leverage IoT and AI technologies. Both paradigms require overcoming resistance to change and ensuring robust infrastructure to achieve optimal operational efficiency.

Future Trends in Industrial Automation and Smart Manufacturing

Future trends in industrial automation emphasize increased integration of artificial intelligence, machine learning, and advanced robotics to enhance precision, efficiency, and predictive maintenance. Smart manufacturing leverages IoT connectivity, real-time data analytics, and digital twins to enable adaptive production processes and reduce downtime. The convergence of edge computing and 5G technology will drive faster decision-making and seamless communication across industrial ecosystems.

Related Important Terms

Digital Twin

Digital Twin technology in smart manufacturing creates real-time virtual replicas of physical assets, enabling predictive maintenance and process optimization, surpassing traditional industrial automation systems that rely on fixed control tasks. This dynamic digital representation integrates IoT data, AI analytics, and simulation models to enhance decision-making and operational efficiency in manufacturing environments.

Edge Computing

Edge computing in industrial automation enhances real-time data processing by minimizing latency and bandwidth usage, enabling faster decision-making on the factory floor. In smart manufacturing, edge computing integrates with IoT devices and AI analytics to optimize production efficiency, predictive maintenance, and adaptive control systems.

Industrial IoT (IIoT)

Industrial Automation relies on programmable logic controllers (PLCs) and robotics to streamline repetitive production tasks, while Smart Manufacturing integrates Industrial Internet of Things (IIoT) technologies to enable real-time data analytics, predictive maintenance, and adaptive process optimization. IIoT connects machinery, sensors, and control systems through cloud platforms and edge computing, driving enhanced operational efficiency and reduced downtime in manufacturing facilities.

OPC UA (Open Platform Communications Unified Architecture)

OPC UA (Open Platform Communications Unified Architecture) enhances Industrial Automation by providing a standardized, secure, and interoperable communication framework between diverse manufacturing devices and control systems. In Smart Manufacturing, OPC UA facilitates real-time data integration and advanced analytics, enabling seamless connectivity across IoT devices, enterprise systems, and cloud platforms to optimize production efficiency and decision-making.

AI-Driven Predictive Maintenance

AI-driven predictive maintenance in industrial automation utilizes sensor data and machine learning algorithms to detect equipment anomalies before failures occur, reducing downtime and maintenance costs. Smart manufacturing integrates this technology within interconnected systems, enabling real-time analytics and adaptive maintenance scheduling for enhanced operational efficiency and asset longevity.

Cyber-Physical Systems (CPS)

Industrial automation relies on Cyber-Physical Systems (CPS) to integrate physical machinery with embedded computing, enabling real-time control and monitoring within manufacturing processes. Smart manufacturing extends CPS functionality by incorporating advanced data analytics, IoT connectivity, and adaptive algorithms to optimize production efficiency and predictive maintenance.

MES Integration (Manufacturing Execution System Integration)

Industrial automation enhances production efficiency through programmable controllers and robotics, whereas smart manufacturing integrates advanced MES systems to enable real-time data analytics, process optimization, and seamless communication across the supply chain. MES integration in smart manufacturing facilitates precise monitoring, quality control, and adaptive scheduling, driving higher agility and informed decision-making on the factory floor.

Autonomous Mobile Robots (AMR)

Autonomous Mobile Robots (AMRs) enhance smart manufacturing by enabling dynamic, flexible material handling and real-time adaptation to production changes, surpassing traditional industrial automation's fixed, repetitive tasks. Integrating AMRs optimizes workflow efficiency, reduces human error, and supports scalable, data-driven decision-making within Industry 4.0 frameworks.

Adaptive Process Control

Industrial automation streamlines manufacturing by utilizing fixed, pre-programmed control systems to enhance efficiency, while smart manufacturing integrates adaptive process control through IoT sensors and AI algorithms, enabling real-time adjustments and predictive maintenance. Adaptive process control dynamically optimizes production parameters based on continuous data analysis, improving product quality, reducing downtime, and increasing operational flexibility.

Digital Thread

Industrial automation primarily focuses on automating physical manufacturing processes through programmable logic controllers (PLCs) and robotics, while smart manufacturing integrates these systems with advanced data analytics and IoT to create a continuous digital thread. This digital thread enables seamless data flow across design, production, and supply chain operations, enhancing real-time decision-making and product lifecycle management.

Industrial Automation vs Smart Manufacturing Infographic

industrydif.com

industrydif.com