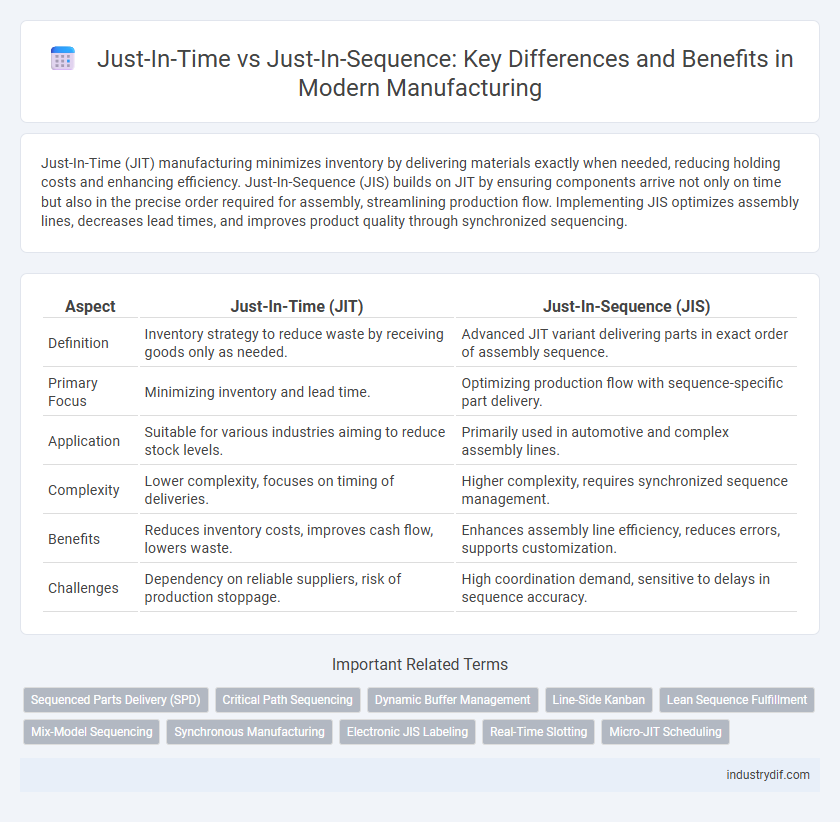

Just-In-Time (JIT) manufacturing minimizes inventory by delivering materials exactly when needed, reducing holding costs and enhancing efficiency. Just-In-Sequence (JIS) builds on JIT by ensuring components arrive not only on time but also in the precise order required for assembly, streamlining production flow. Implementing JIS optimizes assembly lines, decreases lead times, and improves product quality through synchronized sequencing.

Table of Comparison

| Aspect | Just-In-Time (JIT) | Just-In-Sequence (JIS) |

|---|---|---|

| Definition | Inventory strategy to reduce waste by receiving goods only as needed. | Advanced JIT variant delivering parts in exact order of assembly sequence. |

| Primary Focus | Minimizing inventory and lead time. | Optimizing production flow with sequence-specific part delivery. |

| Application | Suitable for various industries aiming to reduce stock levels. | Primarily used in automotive and complex assembly lines. |

| Complexity | Lower complexity, focuses on timing of deliveries. | Higher complexity, requires synchronized sequence management. |

| Benefits | Reduces inventory costs, improves cash flow, lowers waste. | Enhances assembly line efficiency, reduces errors, supports customization. |

| Challenges | Dependency on reliable suppliers, risk of production stoppage. | High coordination demand, sensitive to delays in sequence accuracy. |

Introduction to Just-In-Time (JIT) and Just-In-Sequence (JIS)

Just-In-Time (JIT) manufacturing minimizes inventory by delivering materials exactly when needed in the production process, reducing waste and improving efficiency. Just-In-Sequence (JIS) advances this concept by ensuring components arrive not only on time but in the precise order required for assembly, optimizing workflow and minimizing handling. Both strategies enhance supply chain responsiveness but JIS offers greater precision for complex assembly lines, particularly in automotive manufacturing.

Key Principles of Just-In-Time Manufacturing

Just-In-Time (JIT) manufacturing focuses on minimizing inventory by producing goods only as they are needed in the production process, reducing waste and enhancing efficiency. Key principles of JIT include continuous improvement (Kaizen), demand-driven production, and maintaining close supplier relationships to ensure timely delivery of materials. This method emphasizes quality control at every stage and streamlines workflow to eliminate non-value-added activities.

Just-In-Sequence: Next-Level Supply Chain Efficiency

Just-In-Sequence (JIS) enhances supply chain efficiency by delivering components directly to the production line in the exact order they are needed, minimizing inventory and reducing handling costs. This streamlined approach optimizes assembly processes, improves production flow, and supports lean manufacturing principles better than traditional Just-In-Time (JIT) systems. By synchronizing supplier deliveries with production schedules, JIS reduces waste and boosts overall operational performance.

Core Differences Between JIT and JIS

Just-In-Time (JIT) focuses on reducing inventory by delivering materials exactly when needed for production, while Just-In-Sequence (JIS) refines this by ensuring components arrive in the precise order required for assembly. JIT optimizes inventory levels and reduces waste, whereas JIS enhances production flow by synchronizing delivery sequences with assembly line processes. The core difference lies in JIT's emphasis on timing and inventory control, versus JIS's integration of sequential delivery to match production steps.

Benefits of Implementing Just-In-Time Systems

Just-In-Time systems minimize inventory costs by synchronizing production schedules closely with demand, reducing storage needs and waste. This lean manufacturing approach enhances cash flow and operational efficiency by delivering materials precisely when needed. Improved responsiveness to market changes supports higher product quality and customer satisfaction.

Advantages and Challenges of Just-In-Sequence Production

Just-In-Sequence (JIS) production enhances manufacturing efficiency by delivering components precisely in the order of assembly, reducing inventory costs and minimizing handling time compared to Just-In-Time (JIT) systems. This approach improves synchronization between suppliers and assembly lines, increasing production accuracy and reducing lead times. Challenges include the need for highly reliable logistics, precise scheduling, and strong communication to prevent disruptions that can halt entire production sequences.

Integration of JIT and JIS in Modern Manufacturing

Integrating Just-In-Time (JIT) and Just-In-Sequence (JIS) in modern manufacturing enhances inventory efficiency by synchronizing material deliveries with production schedules, minimizing storage costs. Advanced ERP and IoT technologies enable real-time tracking and precise coordination between suppliers and assembly lines, reducing lead times and waste. This integration supports lean manufacturing principles, improves production flexibility, and accelerates response to demand fluctuations in automotive and electronics industries.

Technology Enablers for JIT and JIS Implementation

Technology enablers such as real-time data analytics, IoT sensors, and advanced ERP systems drive effective Just-In-Time (JIT) manufacturing by optimizing inventory levels and reducing waste. Just-In-Sequence (JIS) implementation benefits from digital twin technology, automated guided vehicles (AGVs), and barcode scanning to ensure precise component sequencing on production lines. Integration of cloud computing and AI-powered predictive maintenance enhances synchronization and responsiveness in both JIT and JIS processes, supporting lean manufacturing goals.

Industry Case Studies: JIT vs. JIS in Action

Industry case studies reveal that Just-In-Time (JIT) manufacturing excels in reducing inventory costs by delivering materials only as needed, while Just-In-Sequence (JIS) enhances production efficiency through synchronized delivery of parts arranged in production order. Automotive manufacturers using JIS reported a 30% reduction in assembly time compared to traditional JIT methods, highlighting its advantage in complex, high-variation production environments. Case analysis from electronics companies shows JIT's strength in minimizing waste, but JIS's ability to streamline workflows and reduce sequencing errors leads to higher overall productivity in highly automated systems.

Future Trends in Production Logistics: JIT and JIS

Future trends in production logistics emphasize the integration of Just-In-Time (JIT) and Just-In-Sequence (JIS) methodologies to enhance efficiency and reduce inventory costs. Advanced data analytics, IoT, and AI-driven forecasting systems enable real-time synchronization of supplies with production schedules, ensuring precise sequencing and minimizing delays. Robotics and automated guided vehicles (AGVs) further optimize JIS implementation by improving accuracy in component delivery and assembly line workflows.

Related Important Terms

Sequenced Parts Delivery (SPD)

Just-In-Time (JIT) manufacturing streamlines inventory by delivering parts exactly when needed, whereas Just-In-Sequence (JIS) enhances this by ensuring Sequenced Parts Delivery (SPD), providing components in precise assembly order to optimize production flow. SPD reduces assembly line downtime and inventory holding costs by synchronizing part delivery with specific production sequences.

Critical Path Sequencing

Just-In-Time (JIT) manufacturing emphasizes producing and delivering goods exactly when needed to minimize inventory, whereas Just-In-Sequence (JIS) refines this approach by aligning component delivery with the exact production sequence, optimizing the critical path. Critical Path Sequencing in JIS ensures precise synchronization of assembly line tasks, reducing downtime and enhancing production flow efficiency in complex manufacturing systems.

Dynamic Buffer Management

Dynamic Buffer Management in Just-In-Time (JIT) manufacturing minimizes inventory by synchronizing production with demand, enhancing efficiency. Just-In-Sequence (JIS) further optimizes this by ensuring components arrive in the exact order of assembly, reducing buffer space and enabling precise line-side delivery.

Line-Side Kanban

Line-Side Kanban in Just-In-Time (JIT) manufacturing emphasizes delivering components precisely when needed to minimize inventory and reduce waste, enhancing production flow with real-time replenishment signals. Just-In-Sequence (JIS) extends JIT by synchronizing component delivery in exact order of assembly, optimizing line-side inventory management and supporting complex, variant-rich manufacturing environments.

Lean Sequence Fulfillment

Just-In-Time (JIT) focuses on minimizing inventory by delivering materials exactly when needed, reducing waste but often requiring stringent supplier reliability and scheduling. Just-In-Sequence (JIS) enhances JIT by delivering components in the exact order of production, optimizing lean sequence fulfillment through synchronized supply chains and reducing assembly line downtime.

Mix-Model Sequencing

Just-In-Time (JIT) optimizes inventory by delivering materials exactly when needed, while Just-In-Sequence (JIS) enhances Mix-Model Sequencing by supplying components in the exact order of production, reducing handling and assembly time. JIS is critical in automotive manufacturing for managing complex product variants efficiently and minimizing production line interruptions.

Synchronous Manufacturing

Just-In-Time (JIT) manufacturing minimizes inventory by synchronizing production with demand, while Just-In-Sequence (JIS) extends this principle by delivering components in the exact order they are needed on the assembly line, enhancing workflow efficiency. Both strategies are critical in synchronous manufacturing systems, aiming to reduce waste, optimize resource utilization, and enable real-time production synchronization with customer orders.

Electronic JIS Labeling

Just-In-Time (JIT) manufacturing emphasizes delivering components precisely when needed to minimize inventory, while Just-In-Sequence (JIS) enhances this by arranging parts in the exact order of assembly, crucial for complex electronic manufacturing. Electronic JIS labeling integrates real-time data tracking and automated identification systems, improving accuracy and efficiency by ensuring that each component matches its specific sequence position on the assembly line.

Real-Time Slotting

Real-time slotting in manufacturing enhances Just-In-Time (JIT) by dynamically adjusting inventory placement to optimize material flow and reduce lead times. In contrast, Just-In-Sequence (JIS) leverages real-time slotting to synchronize component arrivals precisely with the assembly line sequence, minimizing inventory costs and improving production efficiency.

Micro-JIT Scheduling

Micro-JIT Scheduling enhances manufacturing efficiency by synchronizing production sequences with delivery times at a granular level, reducing inventory costs and minimizing waste compared to traditional Just-In-Time methods. Integrating Just-In-Sequence principles enables precise alignment of components with assembly processes, optimizing workflow and ensuring timely part arrival for complex manufacturing systems.

Just-In-Time vs Just-In-Sequence Infographic

industrydif.com

industrydif.com