Manual inspection in manufacturing relies on human judgment and experience to identify defects, offering flexibility but limited scalability and consistency. AI-based inspection leverages machine learning algorithms and computer vision to detect flaws with higher accuracy, speed, and repeatability across large volumes. Integrating AI systems reduces human error and enhances quality control, enabling manufacturers to optimize production efficiency and product reliability.

Table of Comparison

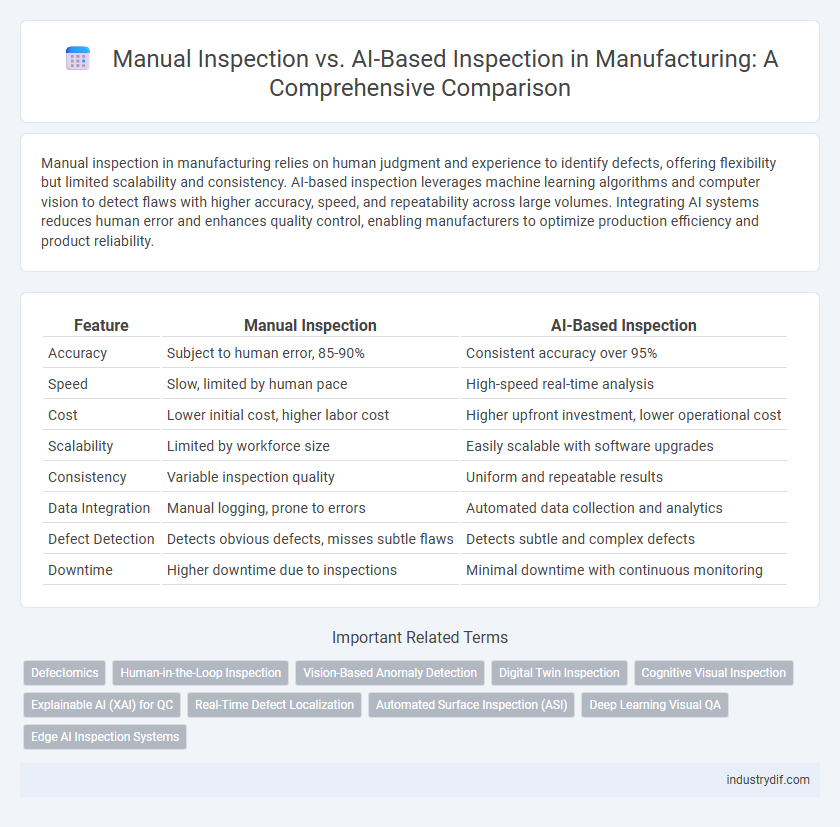

| Feature | Manual Inspection | AI-Based Inspection |

|---|---|---|

| Accuracy | Subject to human error, 85-90% | Consistent accuracy over 95% |

| Speed | Slow, limited by human pace | High-speed real-time analysis |

| Cost | Lower initial cost, higher labor cost | Higher upfront investment, lower operational cost |

| Scalability | Limited by workforce size | Easily scalable with software upgrades |

| Consistency | Variable inspection quality | Uniform and repeatable results |

| Data Integration | Manual logging, prone to errors | Automated data collection and analytics |

| Defect Detection | Detects obvious defects, misses subtle flaws | Detects subtle and complex defects |

| Downtime | Higher downtime due to inspections | Minimal downtime with continuous monitoring |

Introduction to Manual and AI-Based Inspection

Manual inspection relies on human operators to visually examine products for defects, leveraging expert judgment and experience. AI-based inspection employs machine learning algorithms and computer vision technology to rapidly analyze images and detect anomalies with high precision. Integrating AI enhances consistency and efficiency, reducing human error in quality control processes within manufacturing environments.

Key Differences Between Manual and AI-Driven Quality Control

Manual inspection in manufacturing relies on human expertise and visual assessment, often resulting in variable accuracy and slower throughput. AI-based inspection employs machine learning algorithms and computer vision to consistently detect defects with higher precision and faster processing speeds. Key differences include scalability, objectivity, and the ability of AI systems to analyze large datasets for predictive quality control.

Efficiency Comparison: Human Inspectors vs AI Systems

Manual inspection in manufacturing typically suffers from slower throughput and higher error rates due to human fatigue and subjective judgment. AI-based inspection systems leverage computer vision and machine learning algorithms to achieve consistent, high-speed defect detection with accuracy rates often surpassing 95%. This efficiency gain translates into reduced downtime, lower labor costs, and improved product quality control.

Accuracy and Error Rates in Inspection Methods

Manual inspection in manufacturing often suffers from inconsistent accuracy and higher error rates due to human fatigue and subjective judgment. AI-based inspection systems utilize advanced machine learning algorithms and computer vision to consistently identify defects with higher precision and significantly reduced errors. Data from industry studies indicate AI inspection can reduce defect rates by up to 70%, enhancing overall quality control efficiency.

Scalability of Manual versus Automated Inspection

Manual inspection in manufacturing faces scalability challenges due to limited human resources and increased fatigue, leading to inconsistent quality control as production volumes rise. AI-based inspection systems utilize advanced machine learning algorithms and high-resolution imaging to efficiently analyze large datasets, maintaining accuracy and speed regardless of scale. Automated inspection enhances throughput and reduces bottlenecks, enabling manufacturers to meet high demand without compromising defect detection precision.

Cost Implications of Manual and AI-Based Inspection

Manual inspection in manufacturing often incurs higher labor costs and slower throughput due to its reliance on human operators, leading to increased operational expenses. In contrast, AI-based inspection systems require a significant initial investment but reduce long-term costs by improving efficiency, minimizing errors, and decreasing rework rates. Over time, AI-driven solutions offer better cost-effectiveness by enhancing defect detection accuracy and reducing downtime compared to manual inspection methods.

Integration of AI Inspection in Existing Manufacturing Workflows

Integrating AI-based inspection into existing manufacturing workflows enhances defect detection accuracy and accelerates quality control processes without disrupting operational efficiency. AI systems utilize machine learning algorithms to analyze high volumes of visual data in real-time, identifying anomalies that manual inspection might miss. Seamless interoperability with legacy equipment and scalable software solutions enable manufacturers to optimize inspection routines while reducing labor costs and minimizing human error.

Challenges in Adopting AI-Based Inspection Technologies

Manual inspection in manufacturing offers simplicity and direct human judgment, but scalability and consistency issues limit its effectiveness. AI-based inspection technologies face challenges such as high initial costs, integration complexities with existing systems, and the need for large annotated datasets to train accurate models. Overcoming data privacy concerns and ensuring AI interpretability remain critical to successful adoption in production environments.

Impact on Workforce: Upskilling and Job Transformation

Manual inspection in manufacturing requires workers to have specialized skills in identifying defects through direct sensory evaluation, often limiting scalability and consistency. AI-based inspection leverages machine learning algorithms and computer vision, automating defect detection and enabling real-time quality control while necessitating workforce upskilling in data analysis, system management, and maintenance. This shift transforms job roles from routine inspection tasks to higher-skilled positions focused on overseeing AI systems, interpreting data insights, and continuous optimization of manufacturing processes.

Future Trends in Manufacturing Quality Inspection

Future trends in manufacturing quality inspection emphasize a shift from traditional manual inspection methods towards AI-based inspection technologies, which offer enhanced accuracy and real-time defect detection. Adoption of machine learning algorithms and advanced sensors enables predictive maintenance and continuous quality monitoring, reducing downtime and operational costs. Integrating AI-driven inspection systems with IoT and cloud platforms facilitates scalable, data-driven decision-making for improved manufacturing efficiency and product reliability.

Related Important Terms

Defectomics

Manual inspection in manufacturing often struggles with inconsistent defect detection and limited scalability, resulting in higher error rates and slower production cycles. AI-based inspection leverages defectomics to analyze vast datasets of defect patterns, enabling precise identification, classification, and prediction of manufacturing flaws with increased accuracy and efficiency.

Human-in-the-Loop Inspection

Human-in-the-loop inspection integrates expert human judgment with AI-driven automation to enhance accuracy and reduce errors in manufacturing quality control. This approach leverages machine learning algorithms for initial defect detection while relying on human inspectors to validate complex cases and ensure nuanced decision-making.

Vision-Based Anomaly Detection

Vision-based anomaly detection in manufacturing using AI surpasses manual inspection by enabling real-time identification of defects with higher accuracy and consistency, reducing human error and inspection time. Advanced deep learning algorithms analyze complex visual patterns on product surfaces, ensuring early detection of anomalies and improving overall production quality and efficiency.

Digital Twin Inspection

Digital Twin Inspection leverages AI-based models to replicate physical manufacturing processes with real-time data, enabling predictive maintenance and defect detection beyond the capabilities of manual inspection. This technology enhances accuracy and reduces inspection time by simulating various scenarios and identifying anomalies in a virtual environment before they occur on the production line.

Cognitive Visual Inspection

Cognitive visual inspection leverages AI algorithms to enhance defect detection accuracy and consistency compared to traditional manual inspection methods in manufacturing. This technology utilizes machine learning and computer vision to analyze complex patterns at high speed, reducing human error and increasing throughput.

Explainable AI (XAI) for QC

Explainable AI (XAI) enhances AI-based inspection in manufacturing by providing transparent decision-making processes that enable quality control (QC) teams to understand and trust automated defect detection. Unlike manual inspection, XAI integrates interpretable models that highlight specific features leading to quality assessment, improving accuracy and reducing human error in production lines.

Real-Time Defect Localization

Manual inspection relies on human judgment and is often slower with higher error rates, whereas AI-based inspection uses real-time defect localization powered by machine learning algorithms to detect anomalies with greater speed and accuracy. Integrating AI solutions enhances production line efficiency by reducing downtime and enabling immediate corrective actions through precise defect mapping.

Automated Surface Inspection (ASI)

Manual inspection in manufacturing often leads to inconsistent results and higher labor costs, while AI-based Automated Surface Inspection (ASI) enhances defect detection accuracy by leveraging machine learning algorithms and high-resolution imaging. Implementing ASI systems increases production efficiency, reduces human error, and enables real-time quality control in industries such as automotive, electronics, and metal fabrication.

Deep Learning Visual QA

Manual inspection in manufacturing relies heavily on human expertise and is prone to variability and fatigue-related errors, whereas AI-based inspection uses deep learning visual quality assurance to consistently detect defects with higher accuracy and speed. Deep learning models leverage large datasets to identify complex patterns and subtle anomalies that traditional inspection methods often miss, significantly improving overall product quality and reducing operational costs.

Edge AI Inspection Systems

Edge AI inspection systems in manufacturing leverage real-time data processing at the device level, significantly enhancing defect detection accuracy and reducing latency compared to traditional manual inspection methods. These advanced systems enable continuous monitoring and adaptive learning, improving product quality and operational efficiency while minimizing human error and labor costs.

Manual Inspection vs AI-Based Inspection Infographic

industrydif.com

industrydif.com